Needle type glazing kiln tool and porcelain ware glazed firing method thereof

A technology of kiln furniture and glaze firing, which is applied to household utensils, other household utensils, applications, etc., can solve the problems of unsightly appearance, affecting the quality and grade of porcelain products, and achieve full combustion, improve product quality and grade, and reduce slag. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

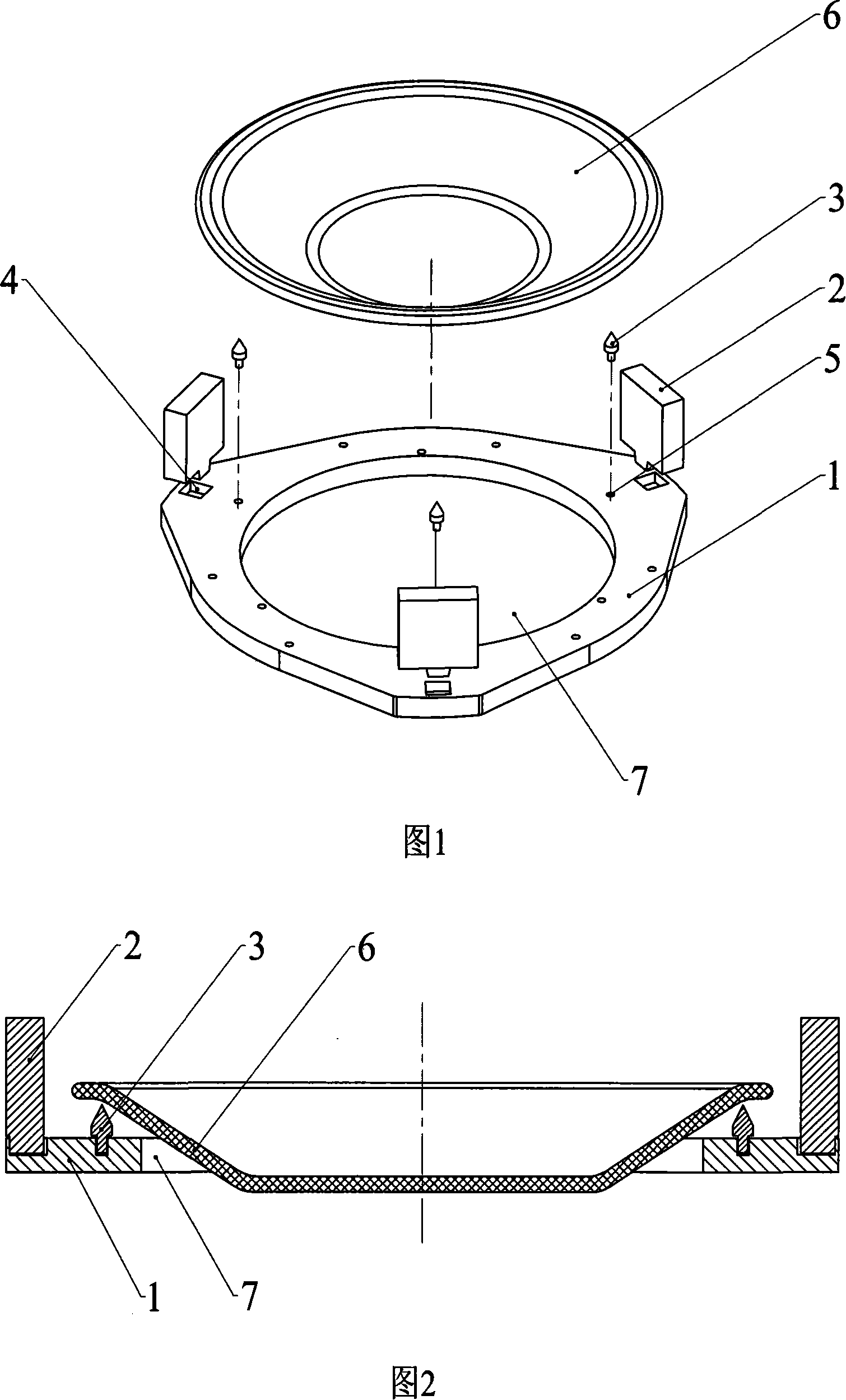

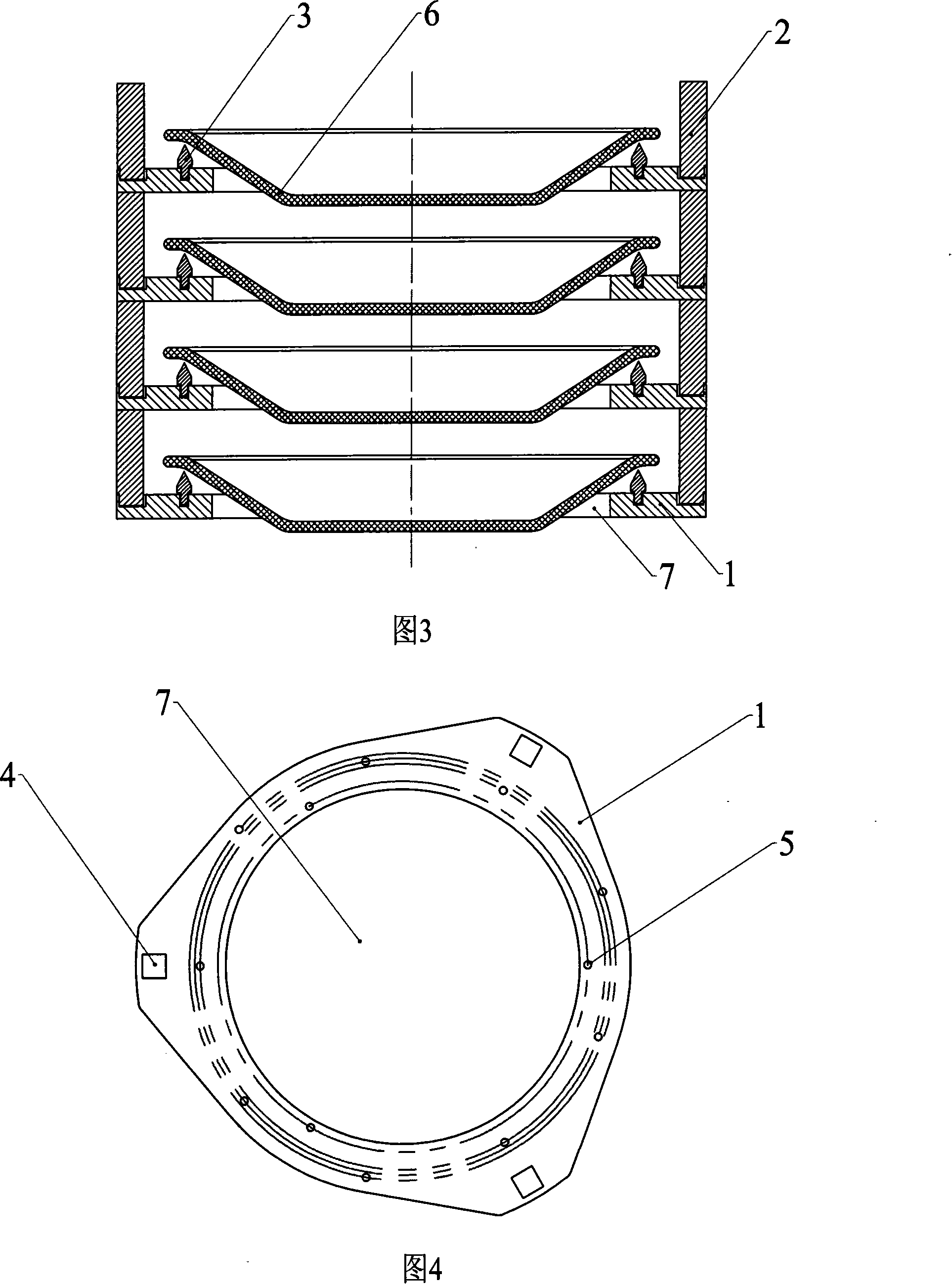

[0026] Embodiment 1: A needle-type glazed firing kiln furniture

[0027] Referring to Fig. 1 to Fig. 3, the present embodiment 1 includes a kiln furniture body 1 and supporting legs 2, and a kiln furniture body 1 is provided with at least three needle supports 3 that are not on the same straight line to form a glazed porcelain needle support plane. ; The kiln furniture body 1 is supported separately by at least three legs 2 that are not on the same straight line, and the legs 2 are fitted and positioned with the leg grooves 4 on the kiln furniture body; The grooves 5 are fit and positioned and connected separately; the kiln furniture body 1 is provided with a hollow part 7 that conforms to the downward extension of the glazed porcelain 6, effectively increasing the loading density of the porcelain.

Embodiment 2

[0028] Embodiment 2: A kind of porcelain glaze firing method of needle type glaze firing kiln furniture

[0029] Referring to Figure 1 to Figure 3, including:

[0030] 1) Place three needle supports that are not on the same straight line on the kiln furniture body to form a glazed porcelain needle support plane;

[0031] 2) The lower part of the glazed porcelain extends downward and passes through the hollow part of the kiln furniture body;

[0032] 3) The main body of the kiln furniture is supported separately by three outriggers that are not on the same straight line, and each layer is stacked on top of each other to form a naked swallowing frame for the glaze-fired porcelain of each layer; when in use, the main body of the kiln furniture It can be fitted and positioned with the outriggers, and can also be bonded firmly with high-temperature adhesives;

[0033] 4) The space between the upper leg and the lower leg and the hollow part of the kiln furniture body conformally m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com