Roller washing and drying machine, and method for controlling drying process

A washing and drying machine and drum type technology, which is applied to the control device of washing machine, washing device, household clothes dryer, etc., can solve the problems of uneven drying and achieve the effect of preventing uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

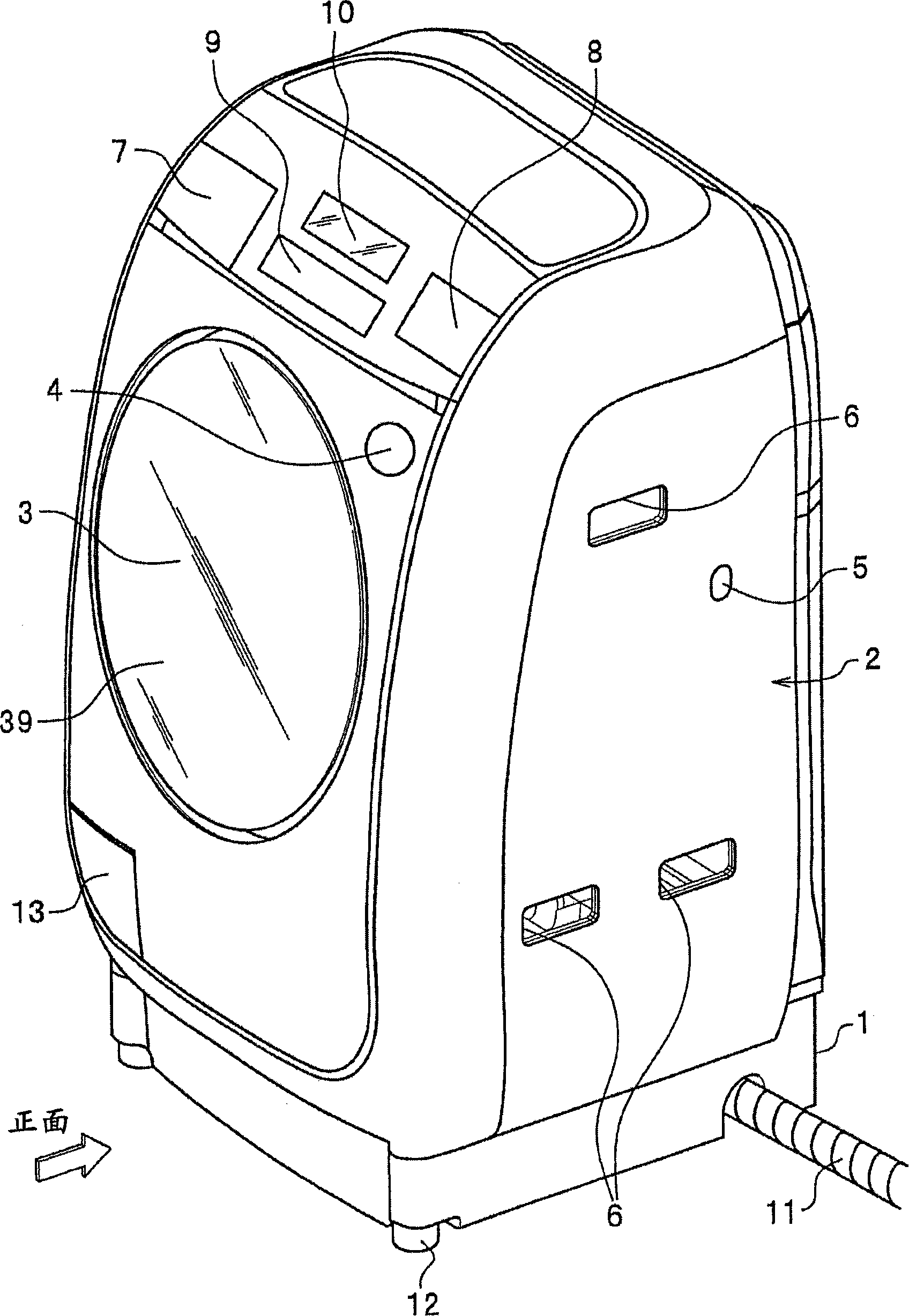

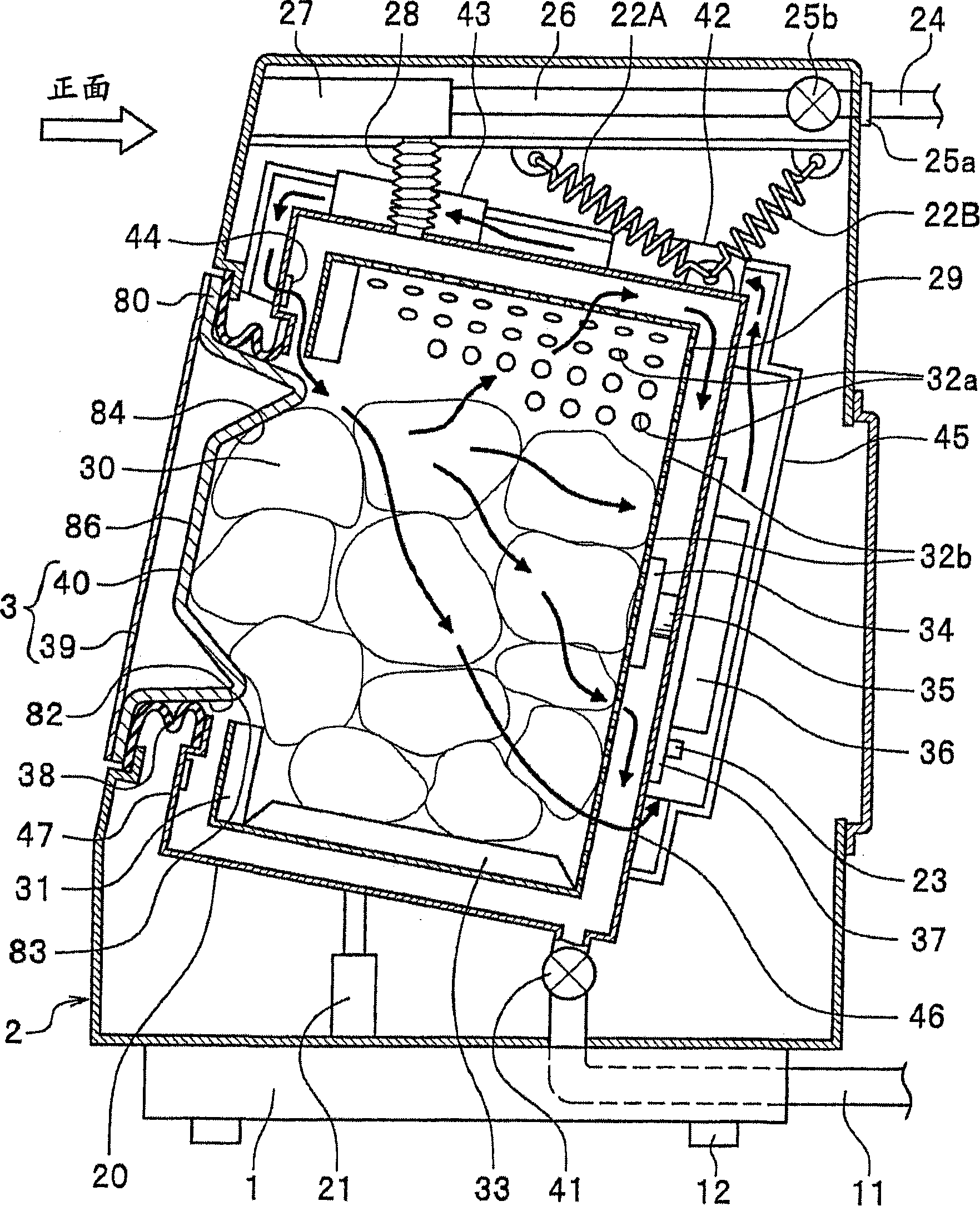

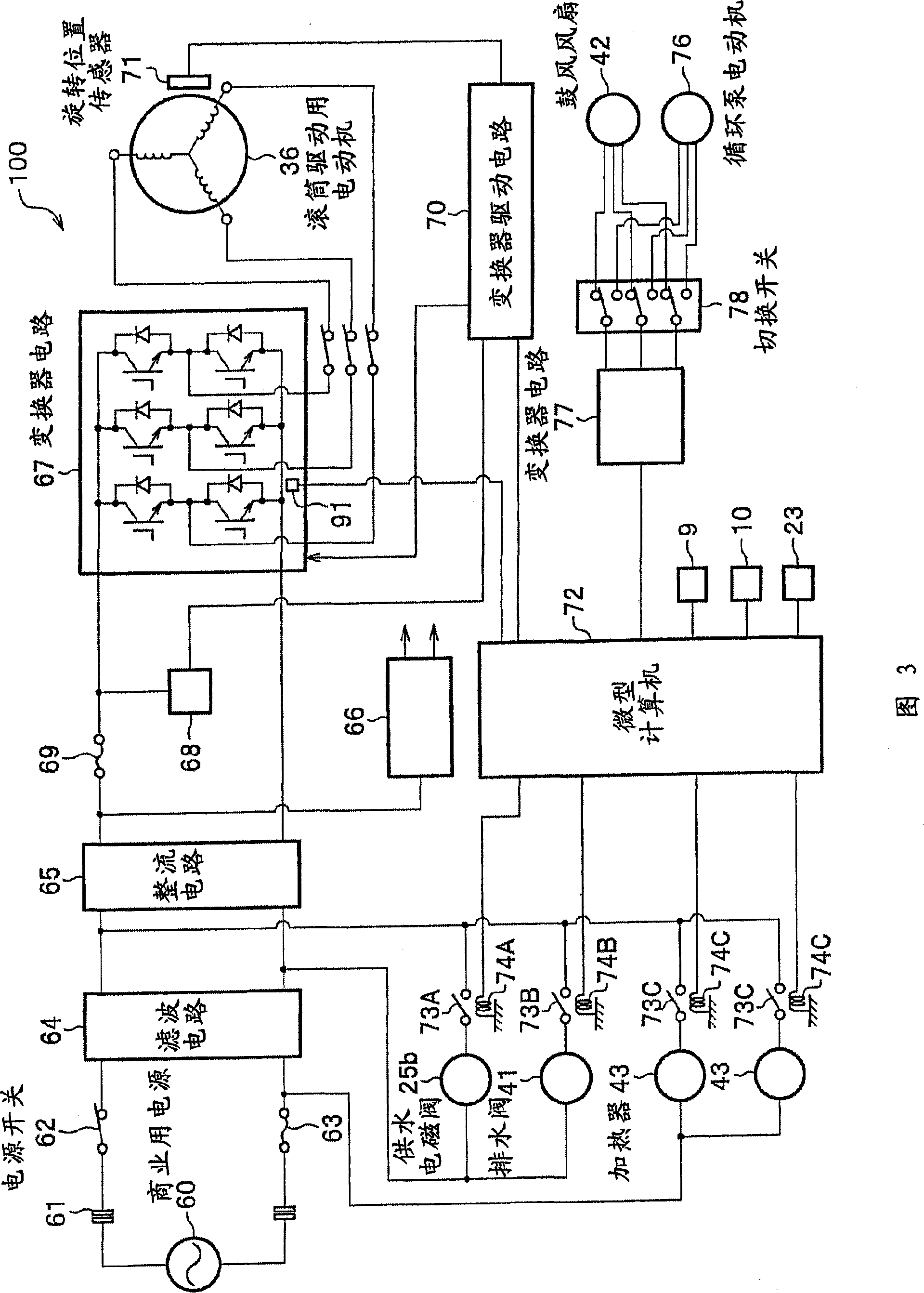

[0016] Next, a drum-type washing and drying machine according to an embodiment of the present invention will be described with reference to the drawings.

[0017] figure 1 It is an external perspective view of the drum type washing and drying machine of this embodiment, figure 2 It is a longitudinal sectional view of a drum type washing and drying machine.

[0018] The drum-type washing and drying machine of this embodiment includes a water supply process, a washing process, a draining process, a dehydration process, a rinsing process, and a drying process in an operation process as mentioned later.

[0019] Such as figure 1 As shown, in the drum type washing and drying machine of this embodiment, the outer frame 2 composed of a combination of steel plate and resin molding is placed on the base 1 .

[0020] The front side of outer frame 2 is provided with taking out and storing laundry 30 (referring to figure 2 ) round door 3, the door 3 can be opened and closed by press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com