Anti-loosing washer and anti-loosing fastening component

An anti-loose washer and anti-loose technology, applied in the direction of threaded fasteners, locking fasteners, washers, etc., can solve the problem that fasteners and serrated washers or fixed objects are loose, there is no tight meshing effect, and the manufacturing process Difficulty and other problems, to achieve effective anti-loosening and anti-backing effect, increase friction resistance, good effect of anti-loosening and anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (Embodiment 1, lock washer)

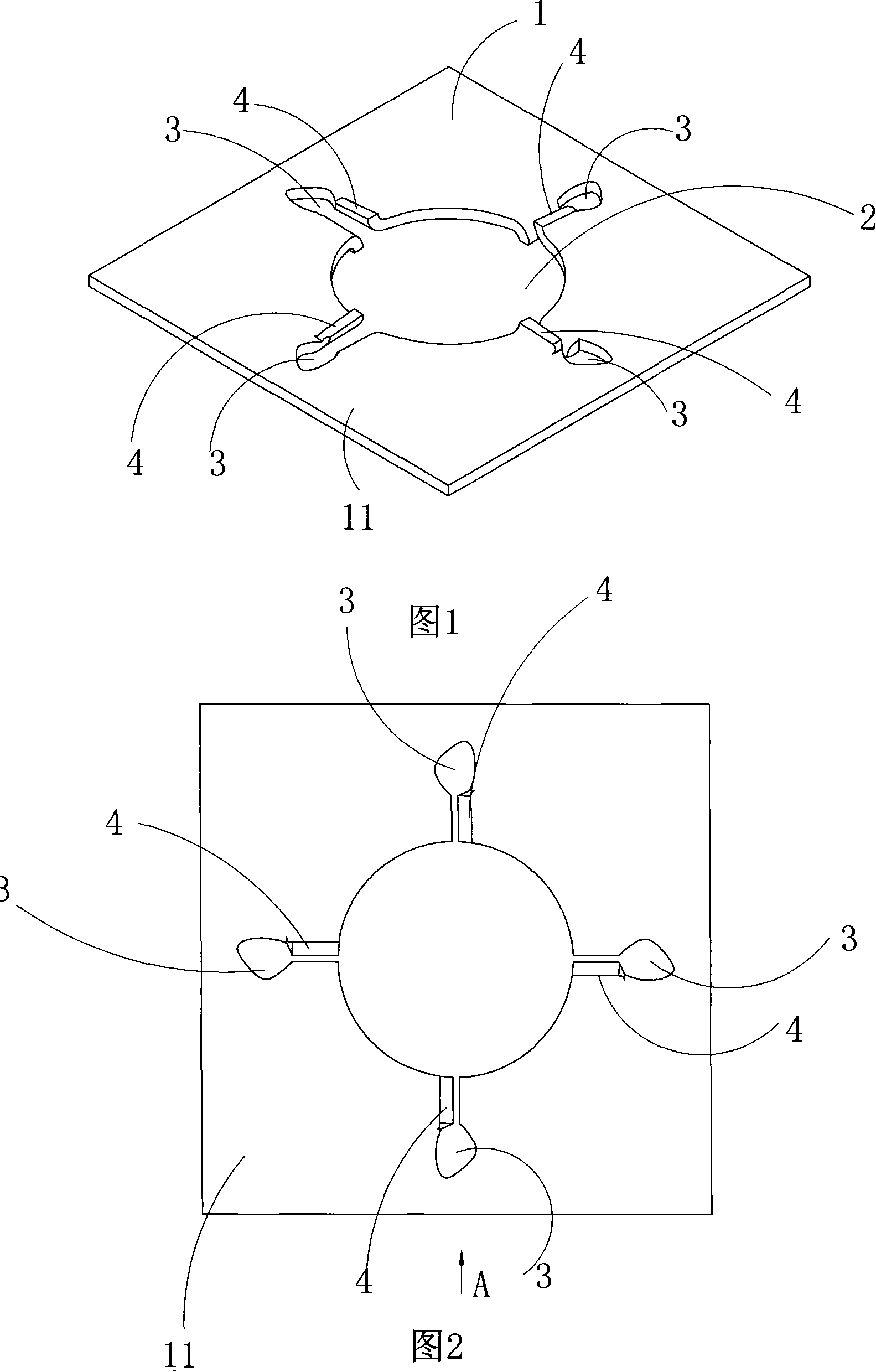

[0035] Figures 1 to 3 show an embodiment of the anti-loosening washer of the present invention; wherein Fig. 1 is a schematic diagram of a three-dimensional structure of the anti-loosening washer of the present invention; Fig. 2 is a view of the anti-loosening washer shown in Fig. 1 when viewed from a top view Schematic diagram of the structure; Figure 3 is a view from the direction A of Figure 2 .

[0036] This embodiment is a kind of anti-loosening washer, see Fig. 1 and Fig. 2, this anti-loosening washer comprises washer main body 1 and the through hole 2 that is arranged in the middle of washer main body 1, and said washer main body 1 includes radially arranged, center A plurality of gaps 3 distributed symmetrically and connected to the through hole 2, the number of gaps 3 in this embodiment is 4, in specific implementation, generally 2 to 6 can be selected according to the size and specific requirements of the gasket; The edge of the ...

Embodiment 2

[0037] (Embodiment 2, lock washer)

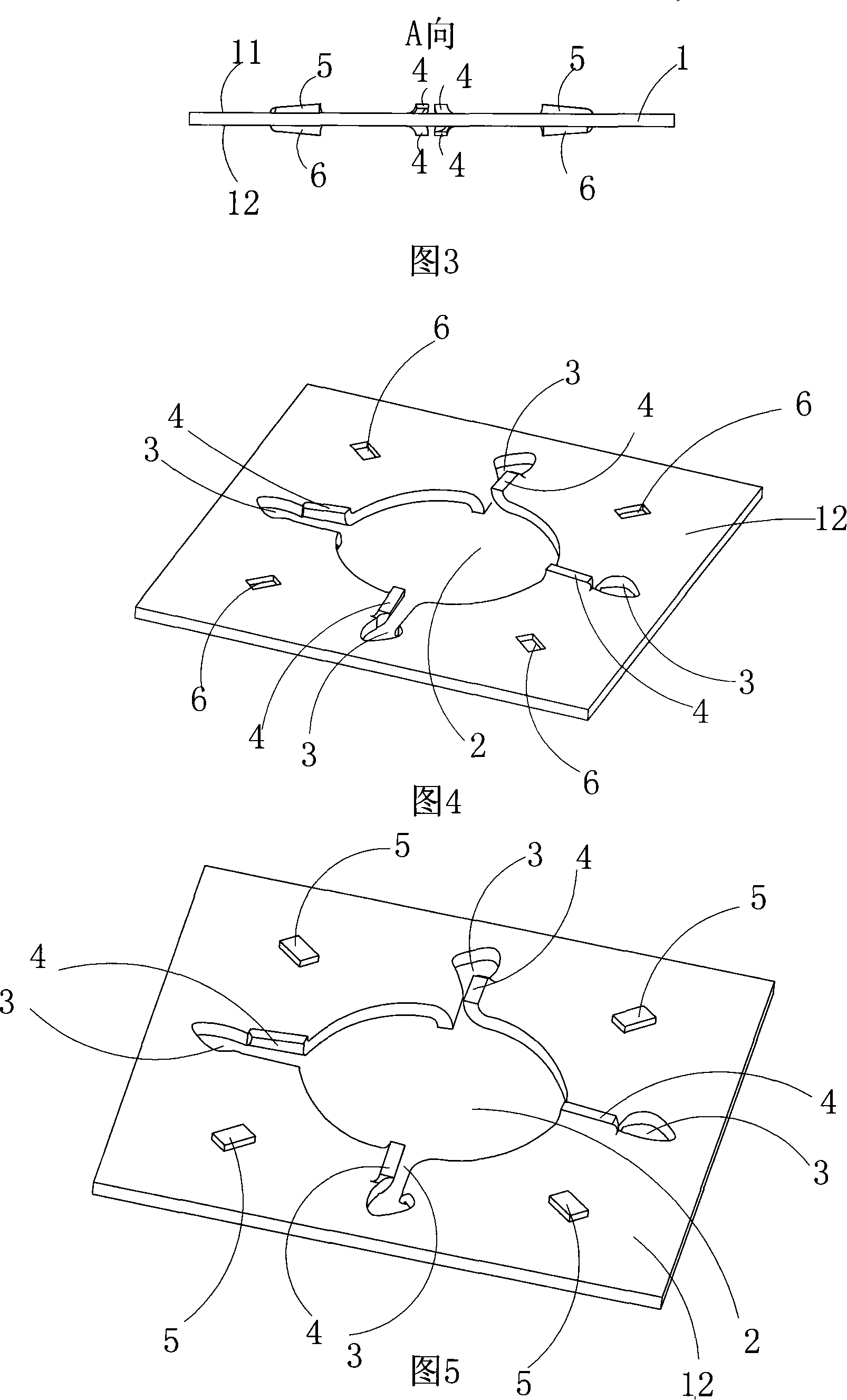

[0038] Fig. 4 is a three-dimensional schematic diagram of another structure of the anti-loosening washer of the present invention, showing the second embodiment of the anti-loosening washer of the present invention.

[0039] This embodiment is basically the same as Embodiment 1, except that: the inner end 12 of the washer body is provided with four concave grooves 6 .

Embodiment 3

[0040] (Embodiment 3, lock washer)

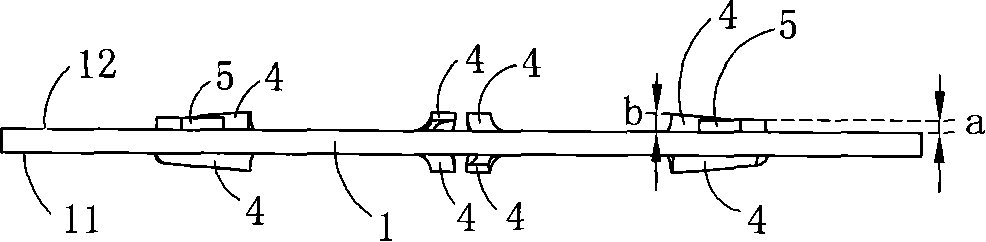

[0041] Figure 5 and Image 6 A third embodiment of the anti-loosening washer of the present invention is shown, wherein FIG. 5 is a schematic perspective view of the third structure of the anti-loosening washer of the present invention; Image 6 It is a structural schematic view of the anti-loosening washer shown in Figure 5 when viewed from the side.

[0042] This embodiment is basically the same as Embodiment 1, except that: the inner end 12 of the washer main body is provided with four protruding bosses 5, and the height a of the bosses 5 is smaller than the height b of the anti-loosening member 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com