LCD module housing and manufacturing method therefor

The technology of a liquid crystal display and its manufacturing method is applied in the field of LCD module casing and its manufacturing, which can solve the problems of wasting steel plate materials, processing flat steel plates, consumption, etc., and achieves the reduction of mold investment costs, the acceleration of production speed, and good economic effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in combination with specific embodiments and accompanying drawings.

[0042] It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the protection scope of the present invention. with the same reference symbols.

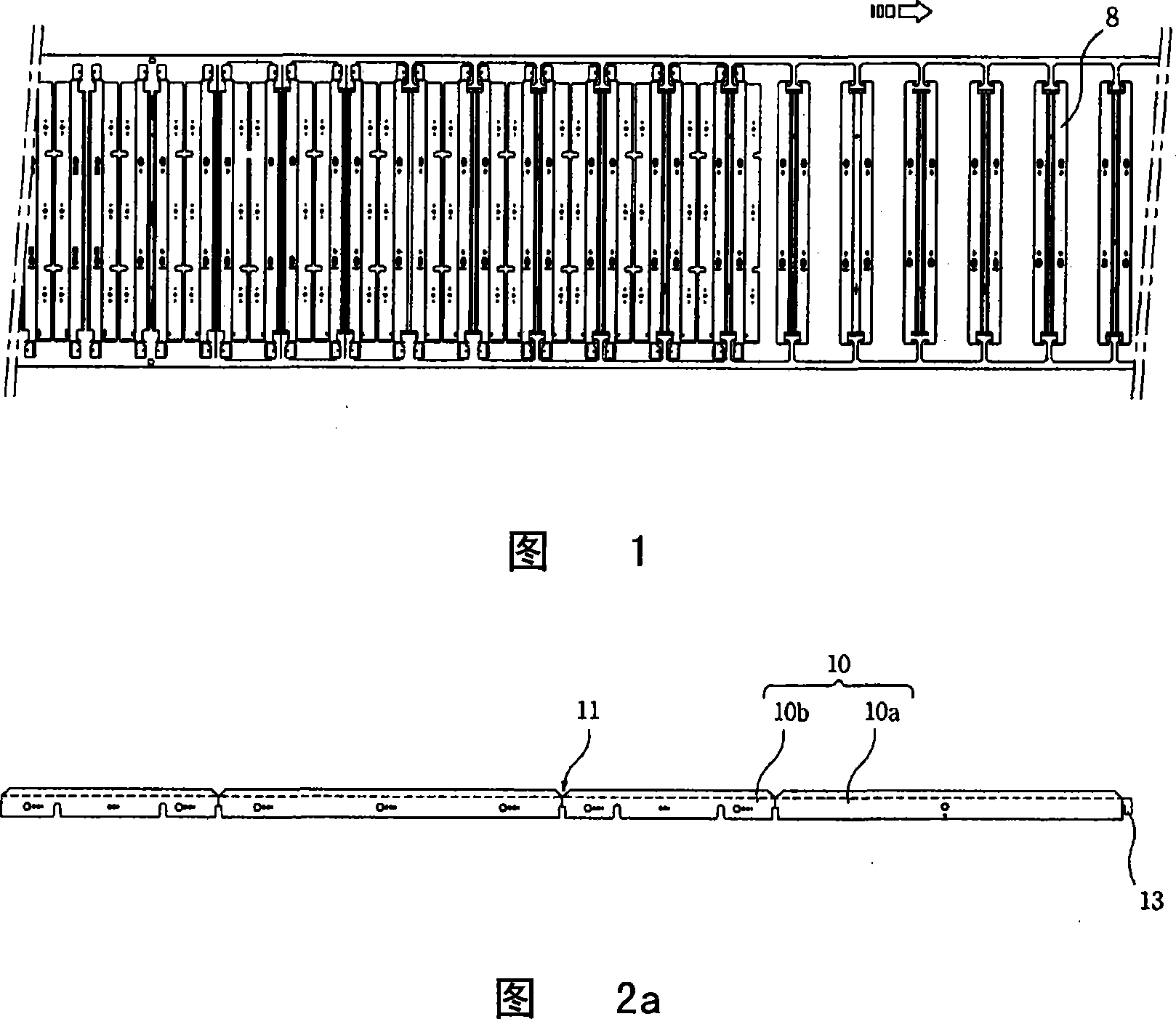

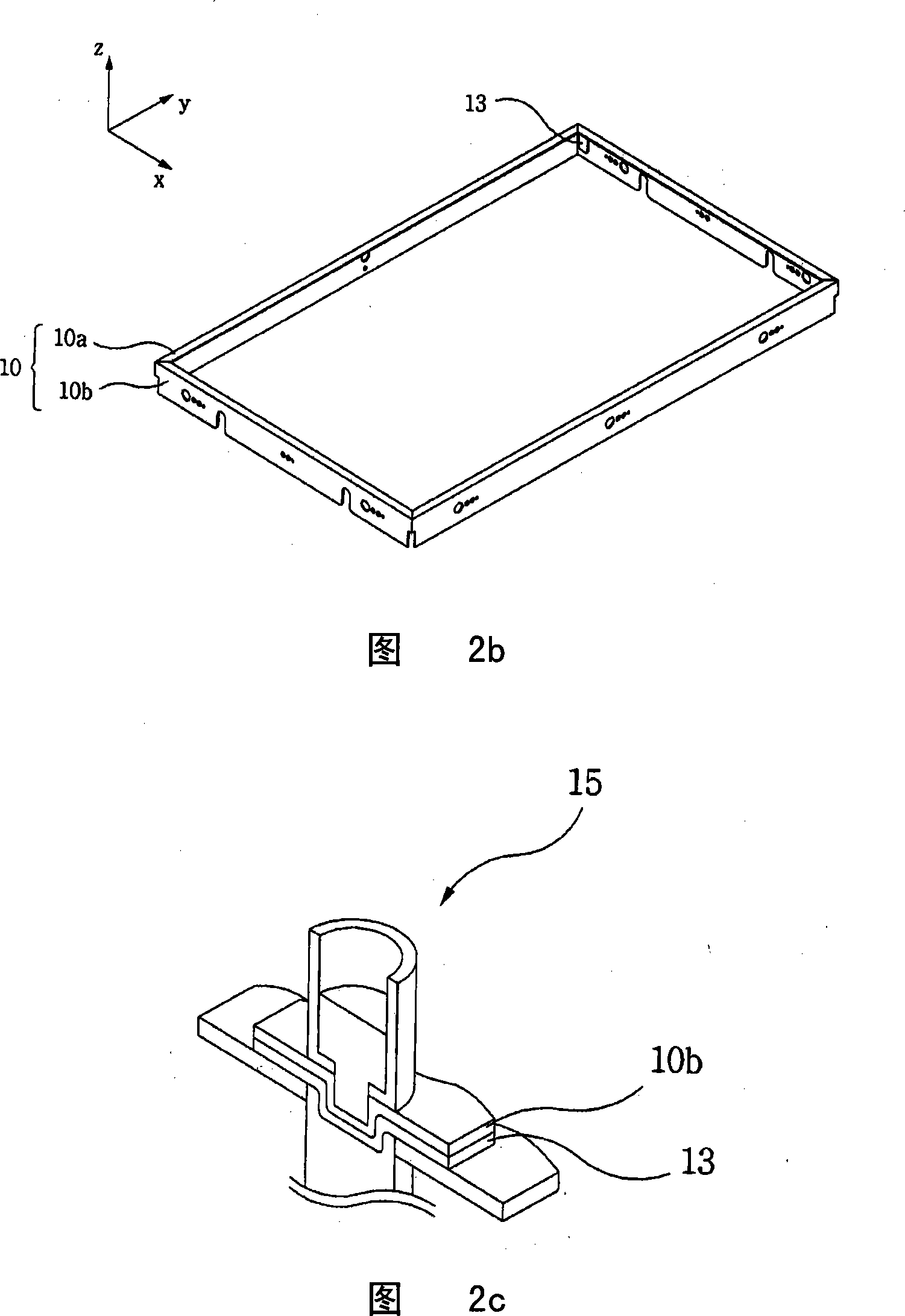

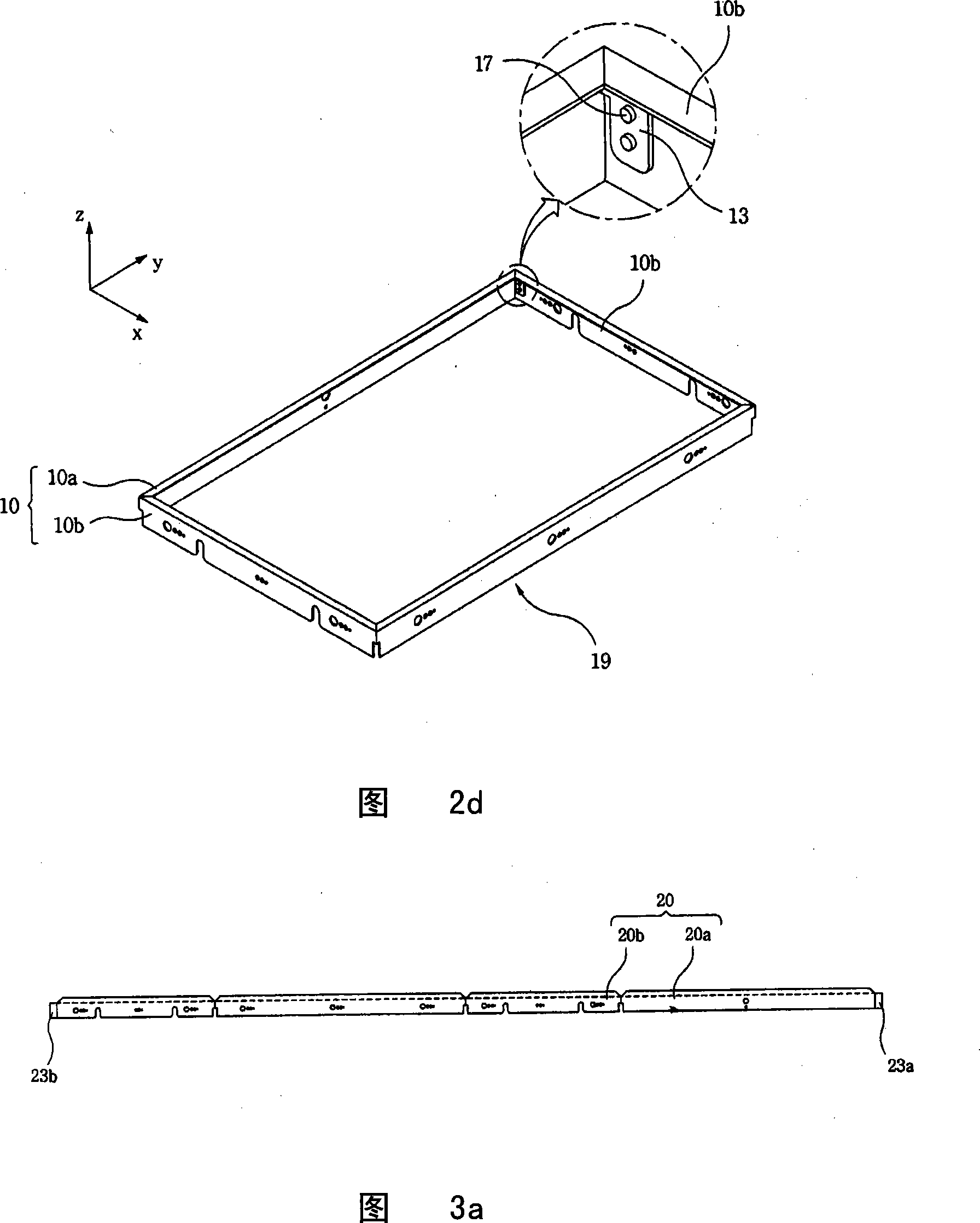

[0043] FIG. 1 is a process flow chart of the manufacturing method of the LCD module housing according to the embodiment of the present invention, which is processed into a linear frame through a progressive type mold.

[0044] As shown in FIG. 1 , the manufacture of the LCD module housing of the embodiment of the present invention is realized through a progressive type mold and continuous stamping and processing of a linear frame. That is, the embodiment of the present invention, unlike the prior art, does not use a flat steel plate cut according to the size of the LCD module, but manufactures the LCD module case by utilizing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com