Transmission device

A technology of transmission device and transmission wheel, which is applied in the direction of transmission device, gear transmission device, transportation and packaging, etc. It can solve problems such as the failure of normal operation of the transmission device, the obstruction of glass substrate production and processing procedures, and the peeling of powder chips, etc., and achieves improvement. Unable to deliver normally, increase production competitiveness, improve delivery interruption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

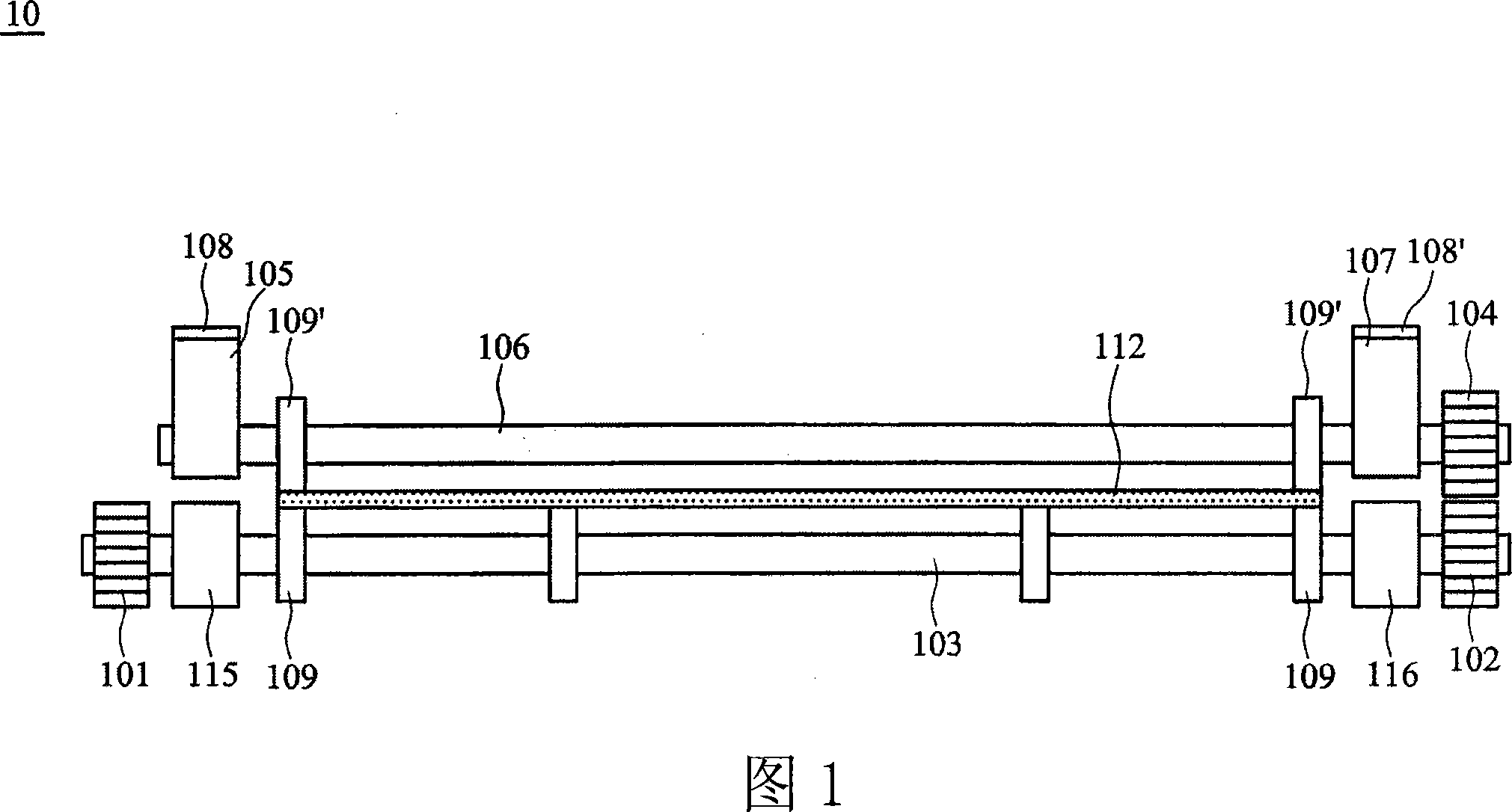

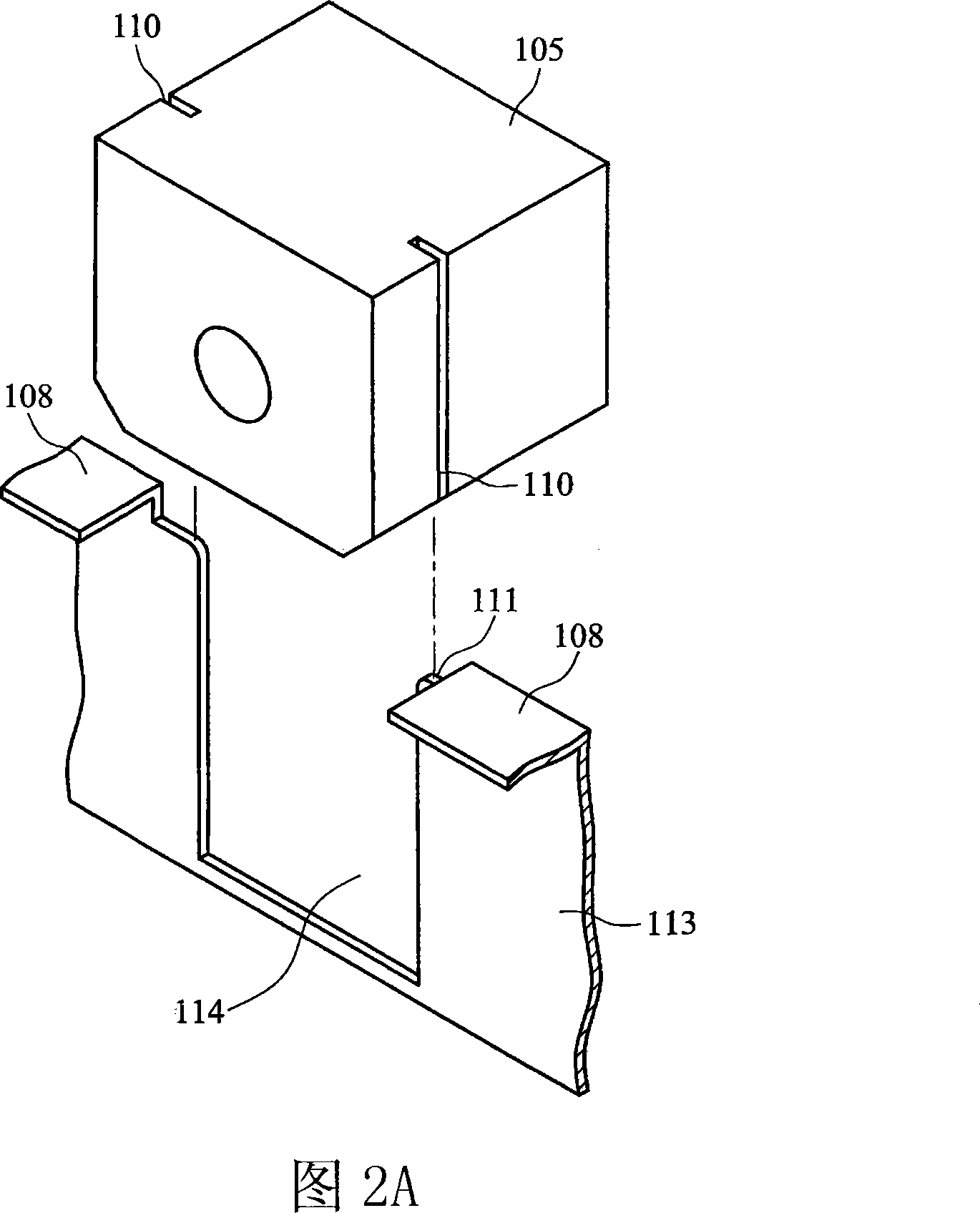

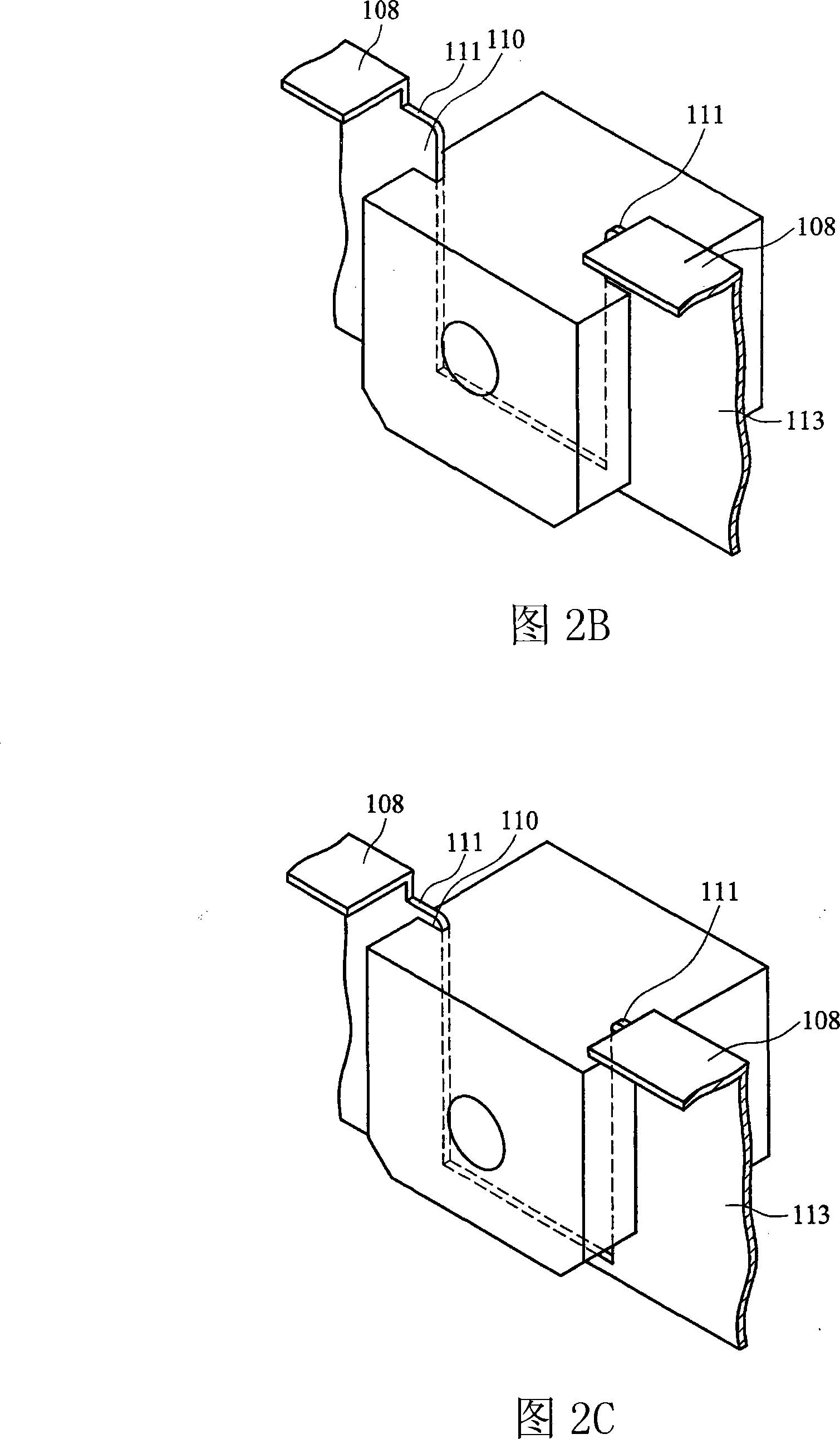

[0080] Fig. 3 shows the schematic diagram of the transmission device embodiment of the present invention, and the transmission device 30 of this embodiment comprises the first transmission wheel 301, the second transmission wheel 302, the lower roller 303, the third transmission wheel 304, the first bearing seat 305, Upper roller 306, first floating assembly 307, second bearing seat 308, second floating assembly 309, first upper cover 310, second upper cover 310', first bearing 321, second bearing 322, and a plurality of rollers Subrings 311, 311'. The link relationship of each component is as follows:

[0081] The lower roller 303 is connected between the first transmission wheel 301 and the second transmission wheel 302, the second transmission wheel 302 is connected (engaged) with the third transmission wheel 304, the upper roller 306 is connected with the third transmission wheel 304, the first Bearing seat 305 is arranged on the top of first bearing 321, and second beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com