Laminated vacuum glass having high safety performance and manufacturing method thereof

A technology of laminated glass and safety performance, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of insecurity, glass fragments falling off the surrounding environment, etc., and achieve the effect of high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

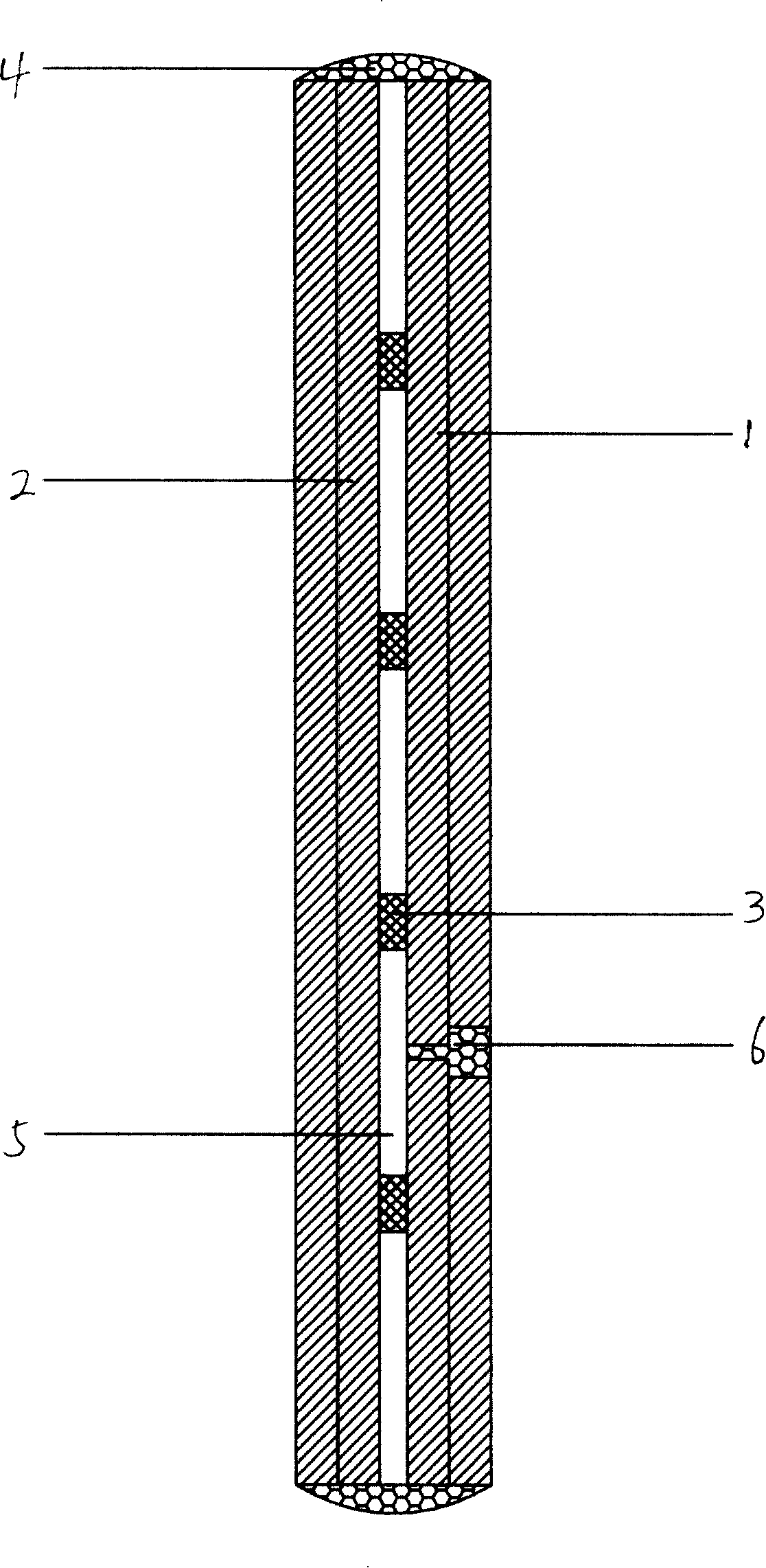

Examples

Embodiment 2

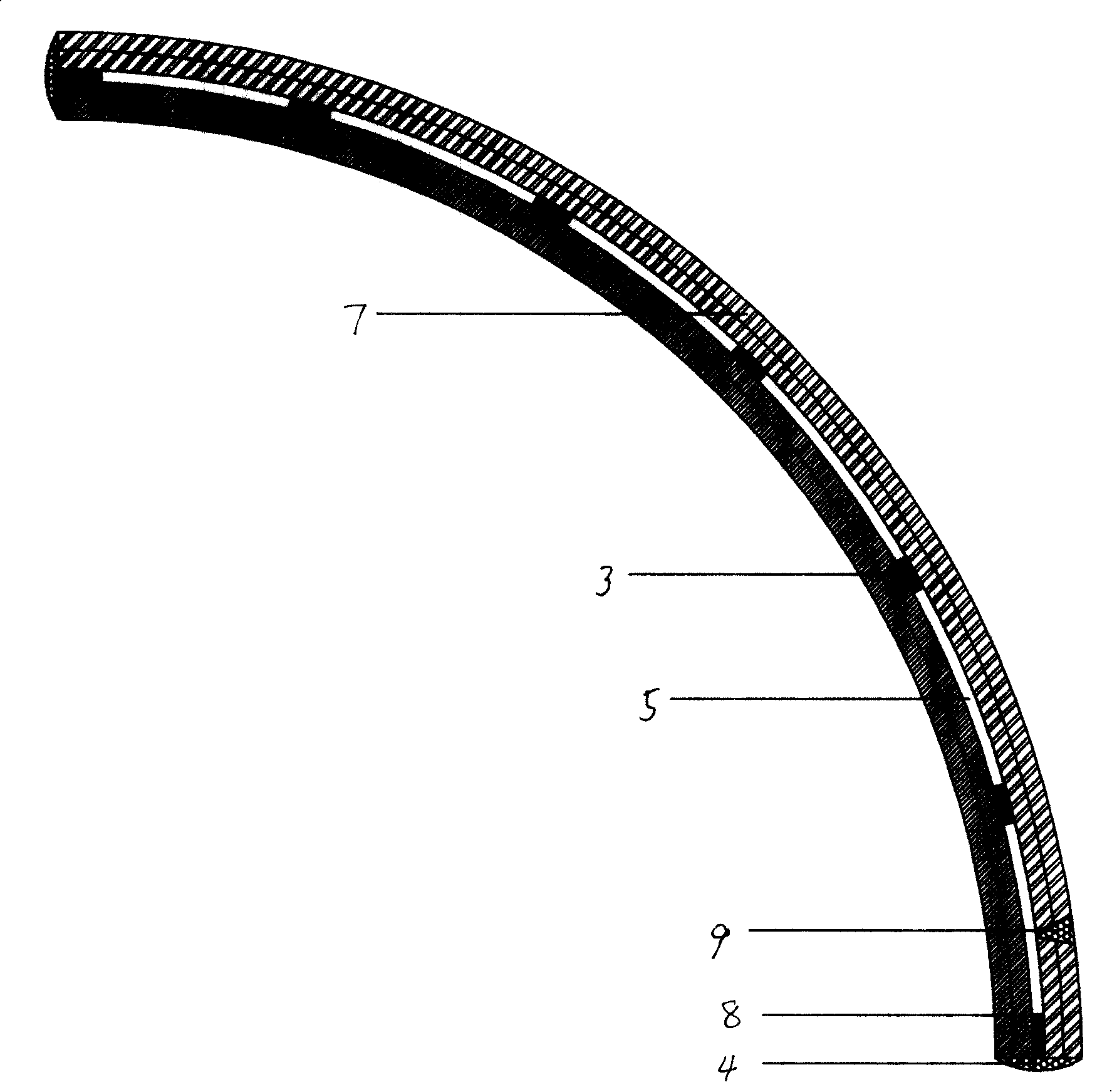

[0025] Such as Figure II As shown, the connection structure in this embodiment is the same as that in Embodiment 1, the difference is that the laminated glass is non-flat laminated glass, one of which is LOW-E coated laminated glass 7, and the other is ordinary laminated glass 8, The air extraction hole adopts a tapered air extraction port 9.

[0026] The use of LOW-E coated laminated glass makes this embodiment have good light wave selective transmission performance, and thus can achieve a better energy saving effect.

[0027] The tapered air extraction hole is used to make air extraction and sealing more convenient, as long as the sealing material is put into the tapered air extraction hole and the air is pumped, a vacuum effect can be obtained.

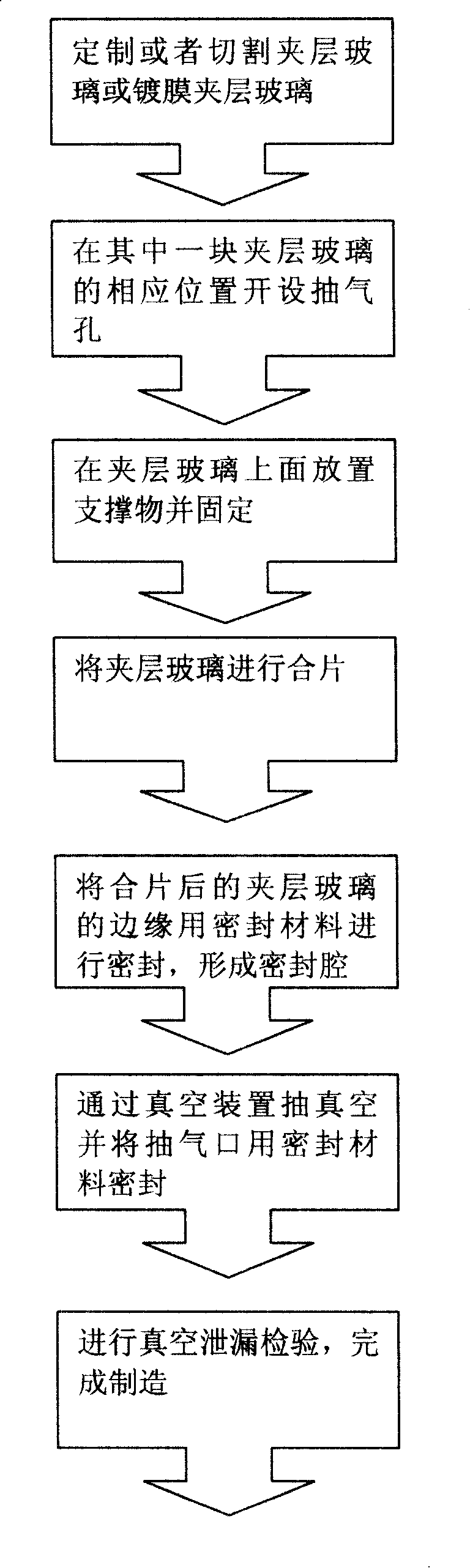

[0028] refer to Figure three As shown, the manufacturing process of this embodiment includes the following steps:

[0029] 1. Customize or cut two pieces of laminated glass according to the size. The selected laminated glass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com