Floor paving structure and paving method

A floor and pavement technology, applied in the direction of building structure, floor, insulation layer, etc., can solve the problems of inability to meet pavement construction requirements, the floor does not reach the service life, the temperature and humidity are greatly different, etc., to eliminate The effect of empty walking, simplified paving work, temperature and humidity equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

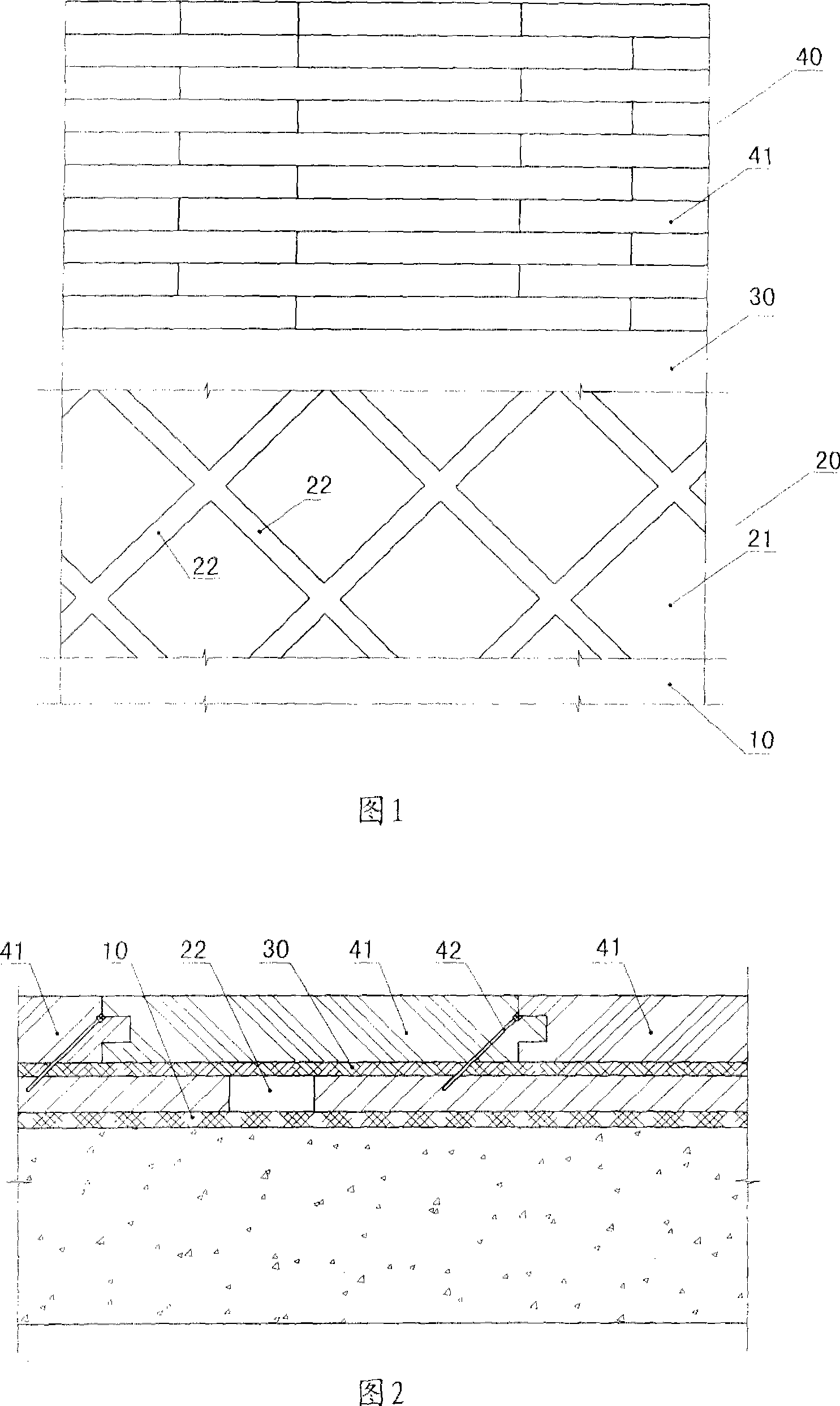

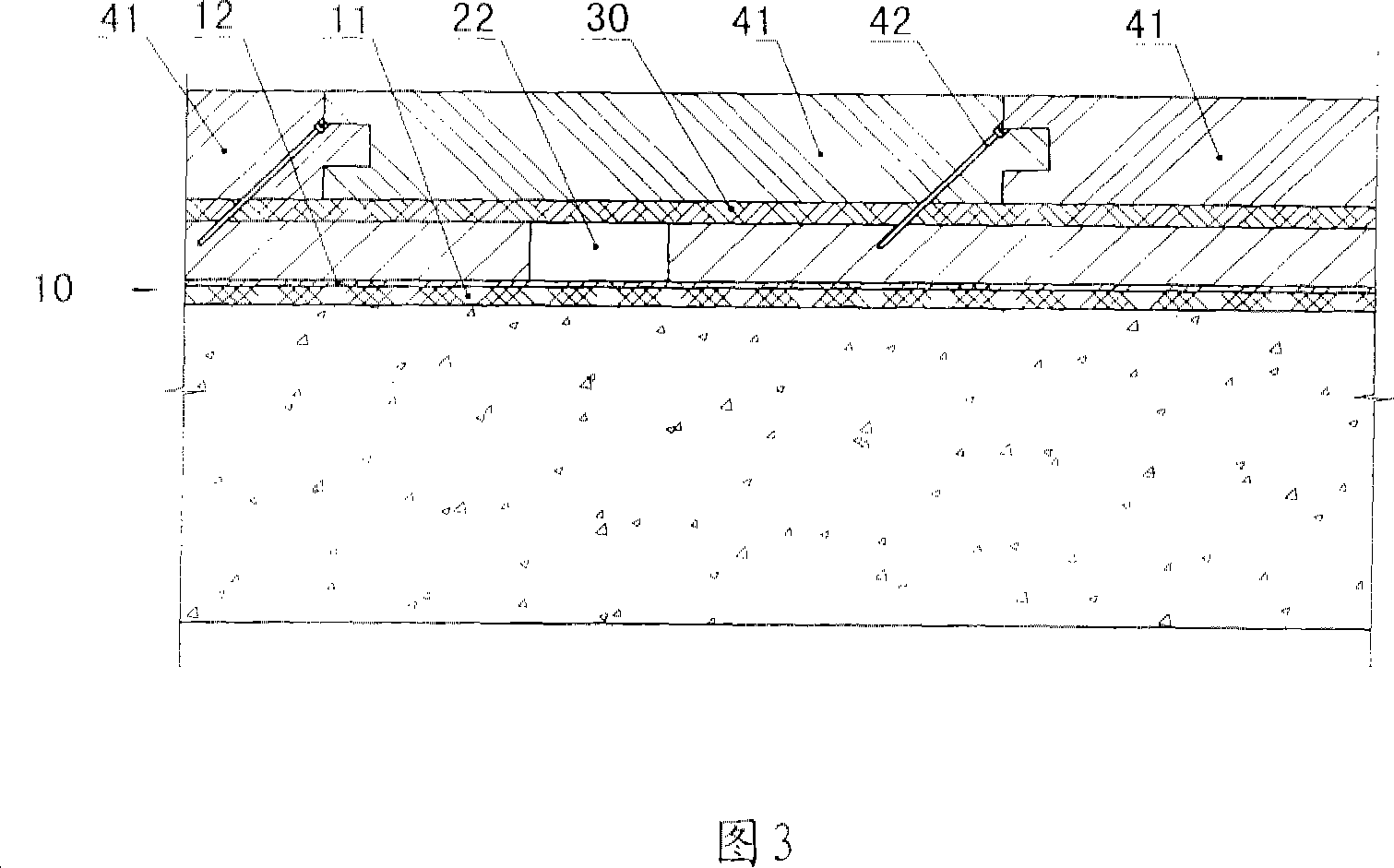

[0019] Referring to Fig. 1 and Fig. 2, the floor pavement structure of the present invention includes a moisture-proof layer 10, a keel layer 20 and a floor 40 sequentially laid on the pavement base surface, and the floor 40 is composed of several floor strips 41. The keel layer 20 is composed of several flat pads 21 arranged at intervals, grooves 22 are formed between the corresponding side walls of each flat pad 21 , and the floor 40 is fixedly connected to the flat pads 21 . Since the solid flat pad 21 is used as the keel structure, there is no large-area closed cavity under any part of the floor 40, so it can effectively eliminate the walking noise, which is conducive to improving and improving the environmental quality of people's work or living places . Because grooves are formed between the corresponding side walls of each flat spacer block 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com