Angle fitting for air-conditioner second throttle

A secondary throttling and air conditioner technology, applied in the direction of fluid circulation arrangements, refrigeration components, refrigerators, etc., can solve problems such as capillary welding difficulties and noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

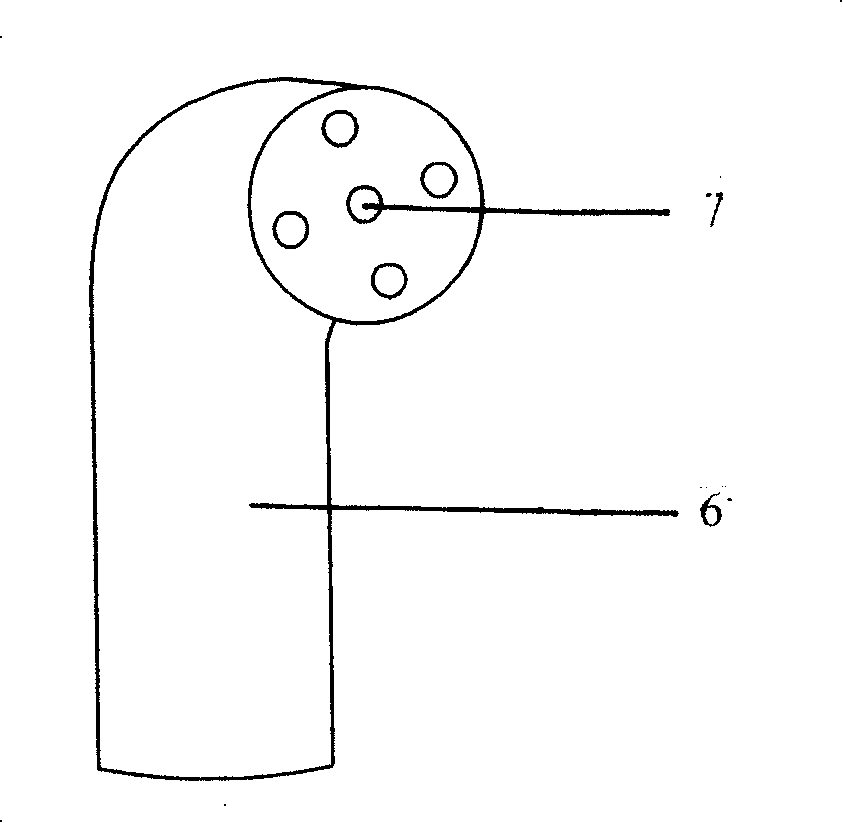

[0030] image 3 It is a sectional view of the elbow for secondary throttling of the present invention.

[0031] Such as image 3 As shown, the shape of the elbow 6 of the present invention is "U" shape, and a plurality of through holes 7 are arranged inside it. The through holes 7 are arranged side by side. In order to achieve the purpose of throttling, the through hole 7 must be thin, similar to a capillary. The number of capillary-shaped through-holes 7 is determined according to throttling requirements, and the number of through-holes 7 is set to five in this embodiment. In order to achieve the original throttling effect, the lengths of all the through holes 7 in the "U" shape must be added together to reach the original length of the capillary 4. In order to transfer heat better, the present invention adopts a round copper material with good he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com