Narrow slit Venturi throttling set and gas-liquid two-phase flow measuring system

A throttling device, Venturi technology, applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, instruments, etc., can solve the problem that it is difficult to ensure that the flow parameters of the two-phase fluid flow through the combined device are consistent , principle error and other issues, to achieve accurate flow pattern and phase holdup measurement, simple implementation, and small device volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

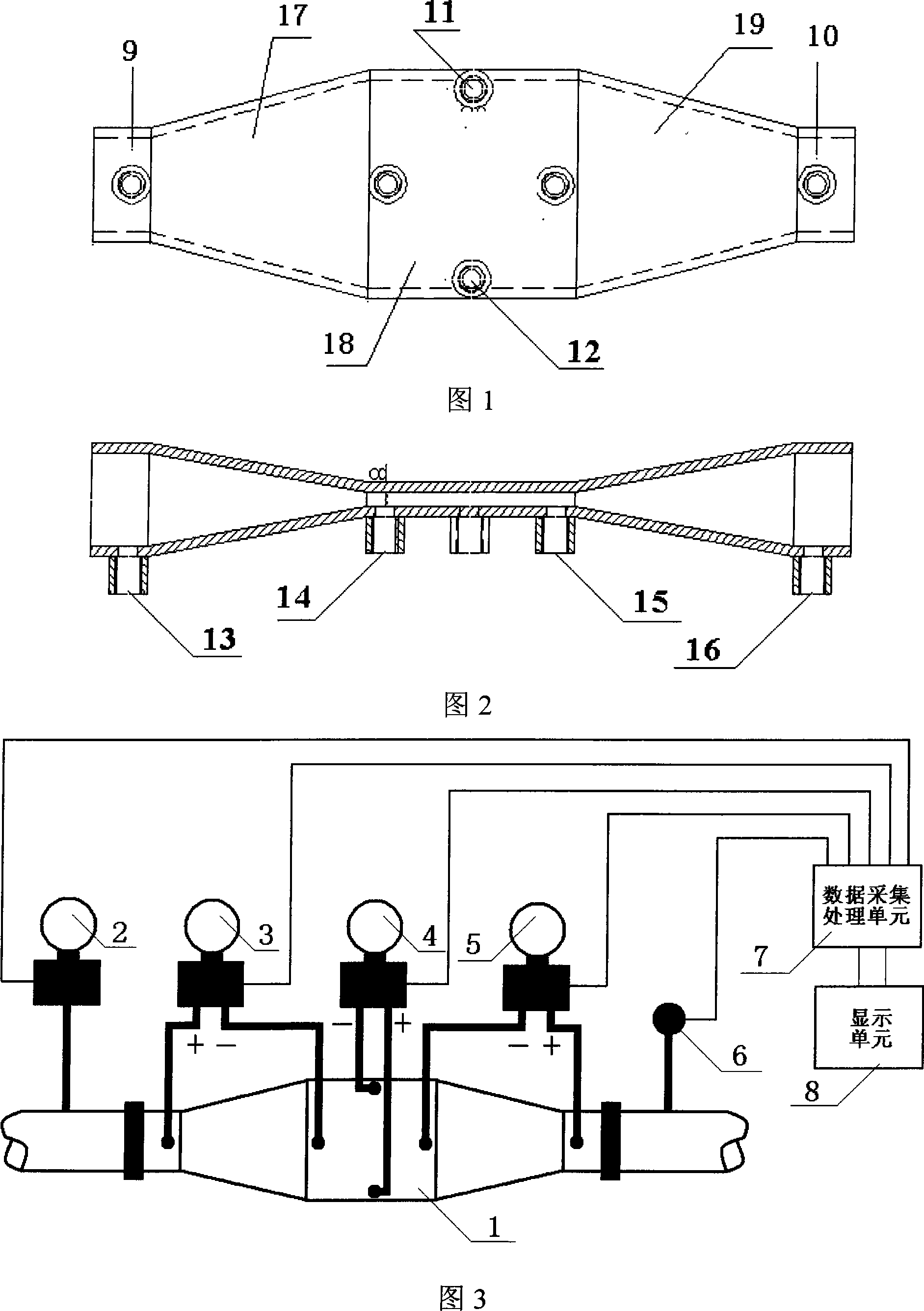

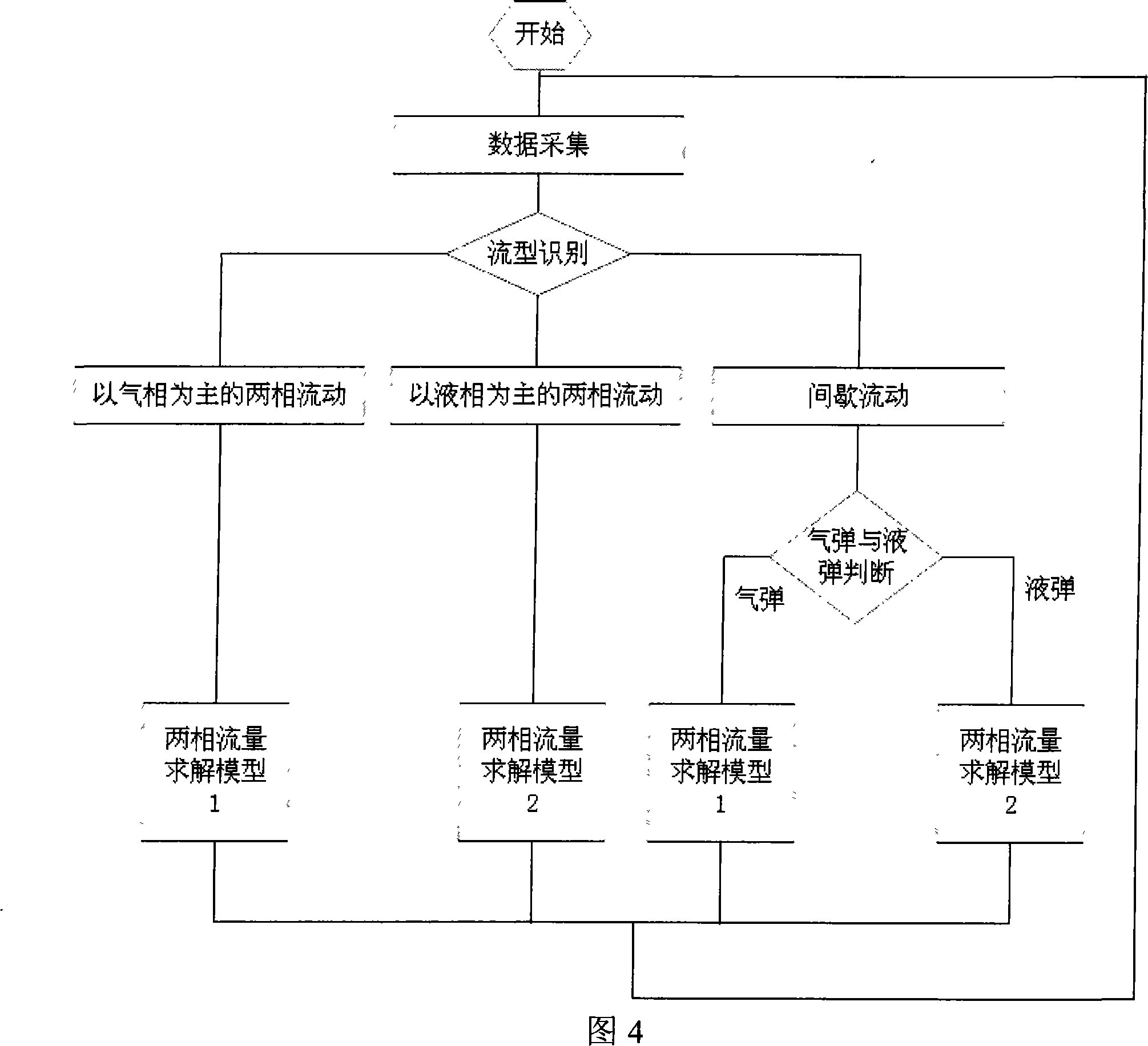

[0015] Referring to Figure 1 and Figure 2, Figure 1 is a front view and Figure 2 is a top view. The slit Venturi throttling device of the present invention includes an inlet 9 , a constriction section 17 , a slit section 18 , an expansion section 19 and an outlet 10 . The slit section 18 in the middle is a long and narrow pipe at one end, and its cross-section is a long and narrow rectangle whose length is much greater than its width. From the front view, the width of the slit section 18 is greater than that of the shrinkage section 17 and the expansion section 19 , and viewed from a top view, the width of the slit segment 18 is much larger than the width of the constriction segment 17 and the expansion segment 19 . The cross-sectional area of the tube of the slit section 18 is smaller than that of the constriction section 17 and the expansio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com