Method for processing poultry products and products thereof

A processing method and poultry technology, applied in the field of food processing, can solve problems such as difficulty in ensuring the freshness of raw materials, influence on product quality, and large difference in thickness, etc., and achieve the effects of good pickling effect, reduced operating costs, and increased freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for processing roast duck products, comprising the following steps:

[0022] (1) Cleaning: slaughter the duck, let it bled, remove the feathers, open the lower part of the belly of the duck to remove the viscera, and rinse;

[0023] (2) Preparation of pickling solution (g): Take 50,000 parts of clear water and put it into a container, then take 3000 parts of table salt, 400 parts of monosodium glutamate, and 1 packet of spices and put it into the container in turn. One of the spice packs contains: 100 parts of fennel, 100 parts of cinnamon, 30 parts of grass fruit, 25 parts of Zanthoxylum bungeanum, 20 parts of fragrant leaves, 15 parts of clove, 10 parts of sand ginger, and 5 parts of licorice. Boil for 2 hours with a slow fire, let it cool to room temperature, and then place it in a refrigerator to drop to 5°C for use.

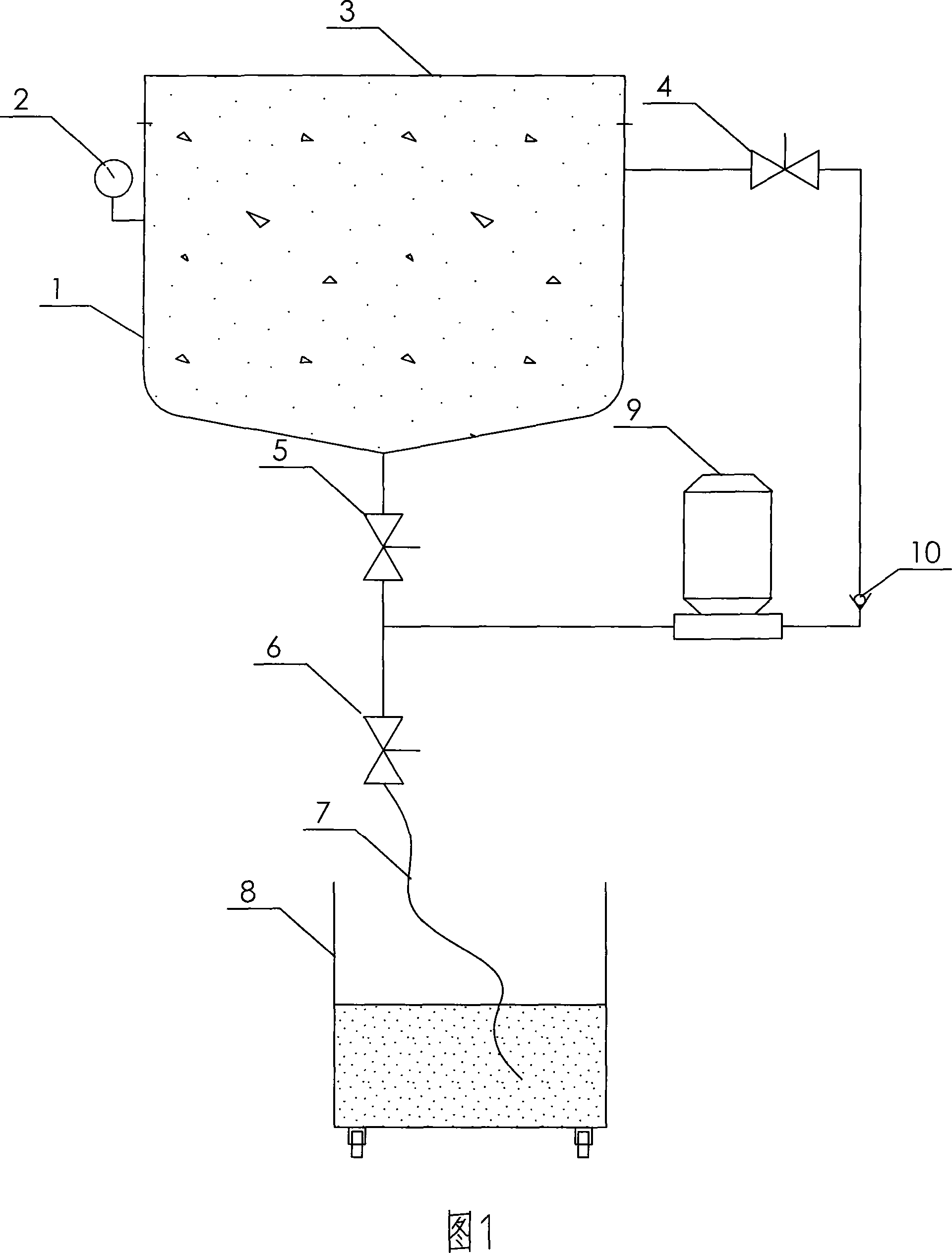

[0024] (3) Injection: Infuse the pickling liquid into the syringe machine, inject 2ml of the pickling liquid into the breast muscles and th...

Embodiment 2

[0032] A method for processing salt-baked chicken products, only need to replace the prepared pickling solution in step (2) of the first embodiment with 25,000 parts of clear water, 1,500 parts of salt, 100 parts of chicken powder, 60 parts of salt curd chicken powder, monosodium glutamate 40 parts, white pepper powder 30 parts, sand ginger powder 20 parts. The pressure value in the step (4) is replaced by 1.5Mpa, and the pickling time is replaced by 2 hours. The rest of the steps are the same as those in Embodiment 1, and will not be repeated in this part.

Embodiment 3

[0034] A method for processing wind duck products, only need to replace the prepared pickling liquid in step (2) of the first embodiment with 50000 parts of clear water, 3000 parts of table salt, 400 parts of monosodium glutamate, 1 package of spices, 1 package of spices contains 100 parts of fennel, 80 parts of cinnamon, 40 parts of grass fruit, 25 parts of Zanthoxylum bungeanum, 20 parts of fragrant leaves, 10 parts of clove, 10 parts of sand ginger, and 5 parts of licorice. The pressure value in the step (4) is 1.2Mpa, and the pickling time is 3 hours. The rest of the steps are the same as those in Embodiment 1, and will not be repeated in this part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com