Powder flame-thrower nozzle

A powder flame and spray gun technology, which is applied in the field of powder flame spray gun nozzles, can solve the problems of low powder feeding rate of spraying powder, and achieve the effects of increasing powder feeding rate, promoting complete combustion, and reducing divergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

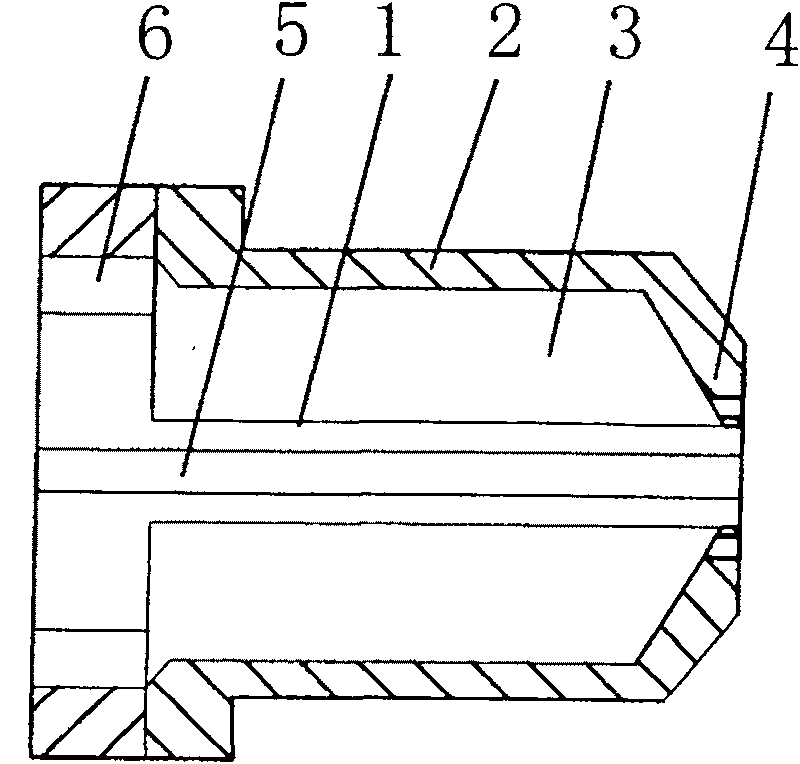

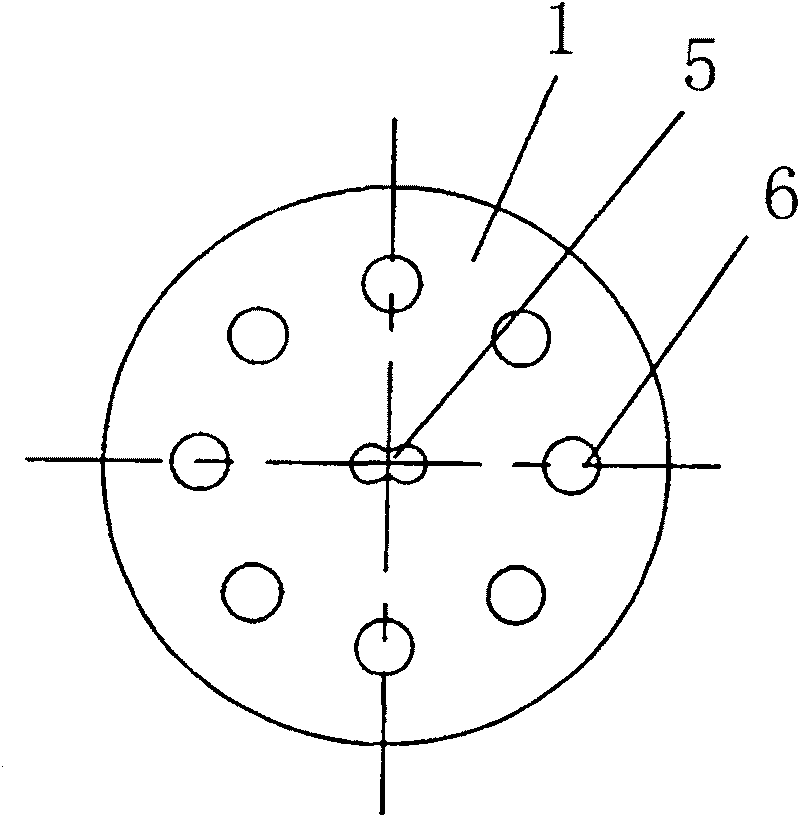

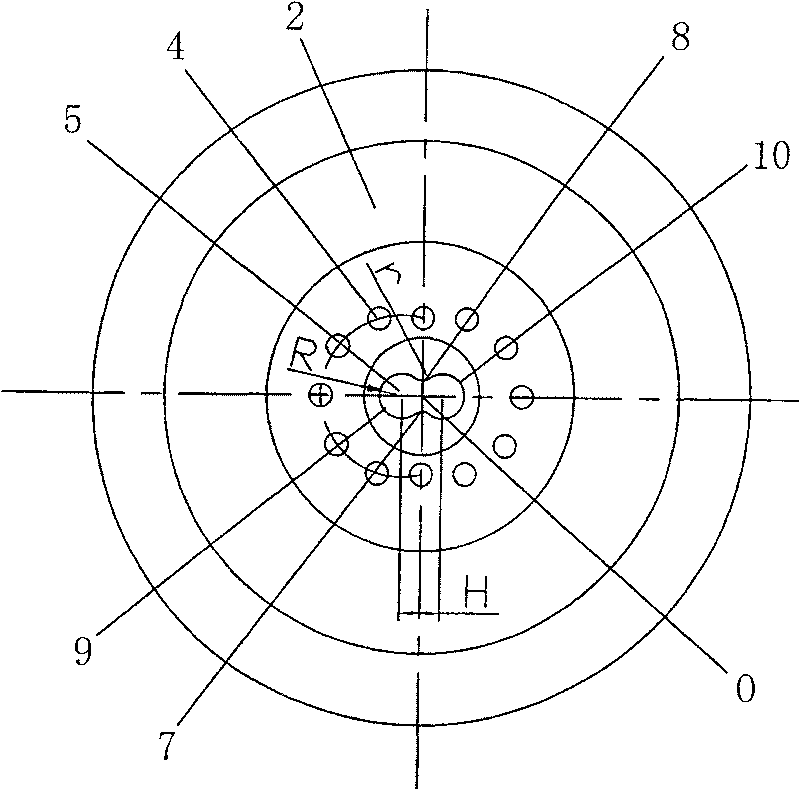

[0017] Such as figure 1 , figure 2 , image 3 As shown, a powder flame spray gun nozzle of the present invention includes an inner core 1 and an outer jacket 2 made of red copper, a mixing chamber 3 is formed between the inner core 1 and the outer jacket 2, and the left end of the inner core 1 is provided with several Evenly distributed air intake holes 6 are characterized in that the center of the inner core 1 has a powder feeding hole 5, and the cross section of the powder feeding hole 5 is composed of two symmetrical convex arcs 7, 8 and two symmetrical concave arcs 9 , 10 are smoothly connected, and the convex arcs 7, 8 are tangent to the concave arcs 9, 10, the radius of the convex arcs 7, 8 is less than the radius of the concave arcs 9, 10; the right end of the coat 2 is provided with a surrounding powder feeding Several air outlet holes 4 of the hole 5, two lines formed by the connection line between the center of any air outlet hole 4 and the center of the powder f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com