Cellular composite board and decorative structure containing the same

A technology for honeycomb composite panels and decorative structures, applied in building components, building structures, covering/lining, etc., can solve problems such as shedding, decreased bonding strength, limited bonding force, etc., to achieve easy adjustment, accurate position, and guaranteed The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] best practice

[0029] The present invention takes a decorative curtain wall arranged on the outer wall of a building as an example, and the curtain wall is assembled by using the honeycomb composite panel provided by the present invention. Of course, the application of the honeycomb composite panel is not limited thereto, and can be used in other various decorative structures.

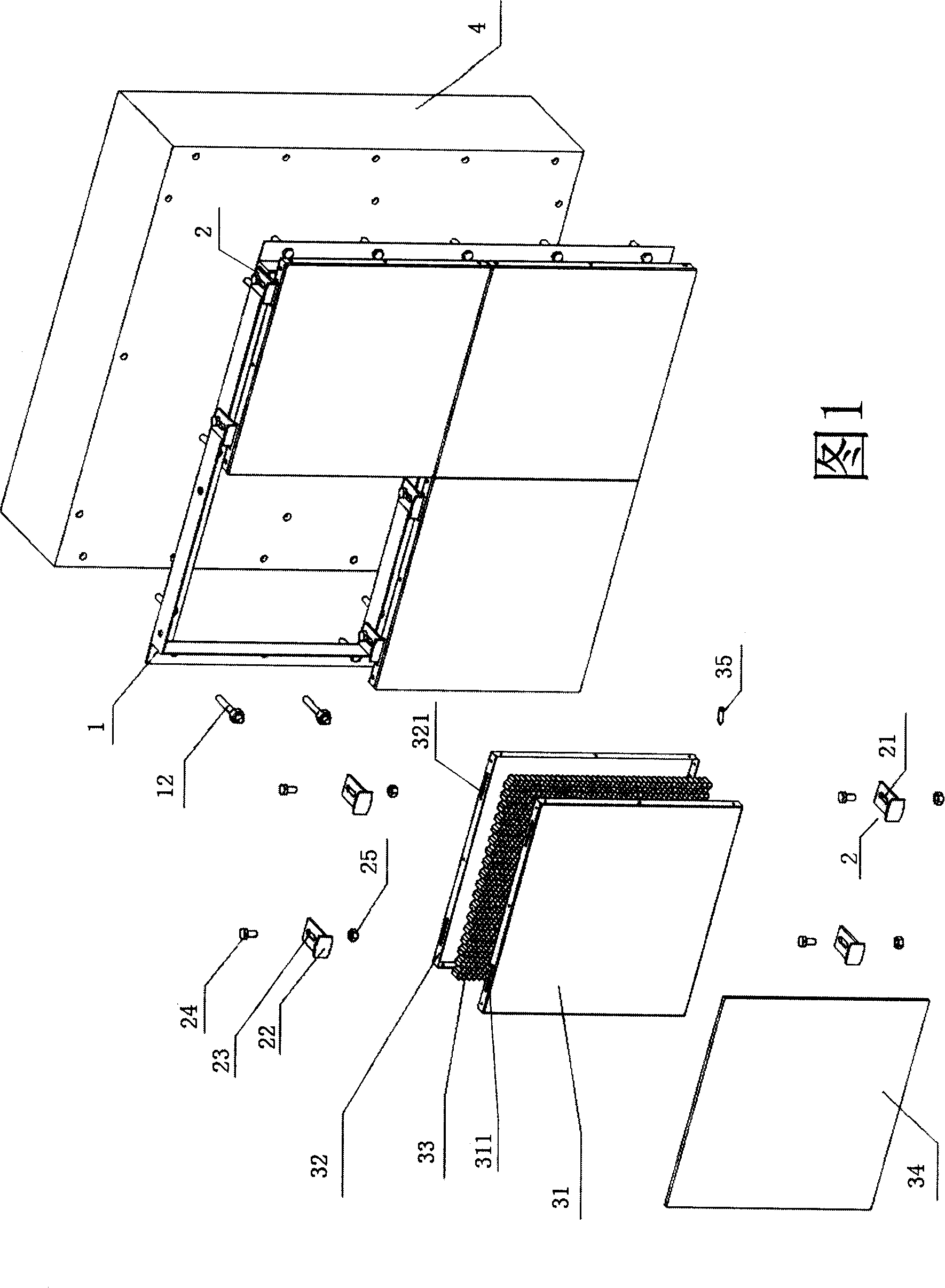

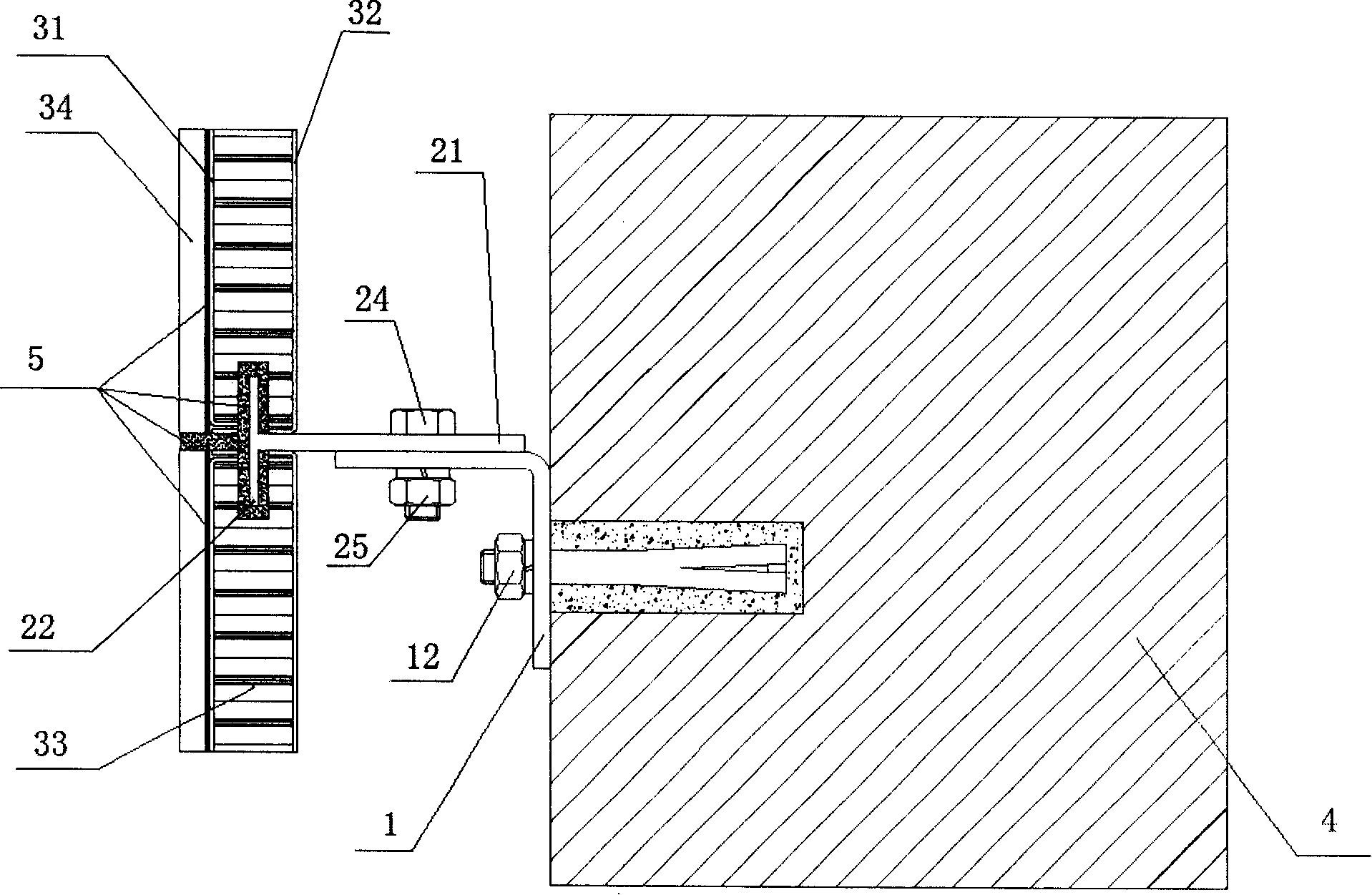

[0030] Referring to Figure 1, figure 2 , the curtain wall includes:

[0031] Skeleton 1 is a frame structure connected by angle steel.

[0032] The T-shaped pendant 2 has a pendant body 21 and a hook portion 22 extending up and down perpendicular to the pendant body 21 , and the pendant body 21 has a mounting hole 23 extending along its length.

[0033] A plurality of honeycomb composite panels 3 are arranged horizontally and vertically. Each honeycomb composite board includes a small inner gusset 31 , a large outer gusset 32 , a honeycomb core board 33 and a marble / granite thin board 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com