Method for preventing example from being oxygenized by double silica tube

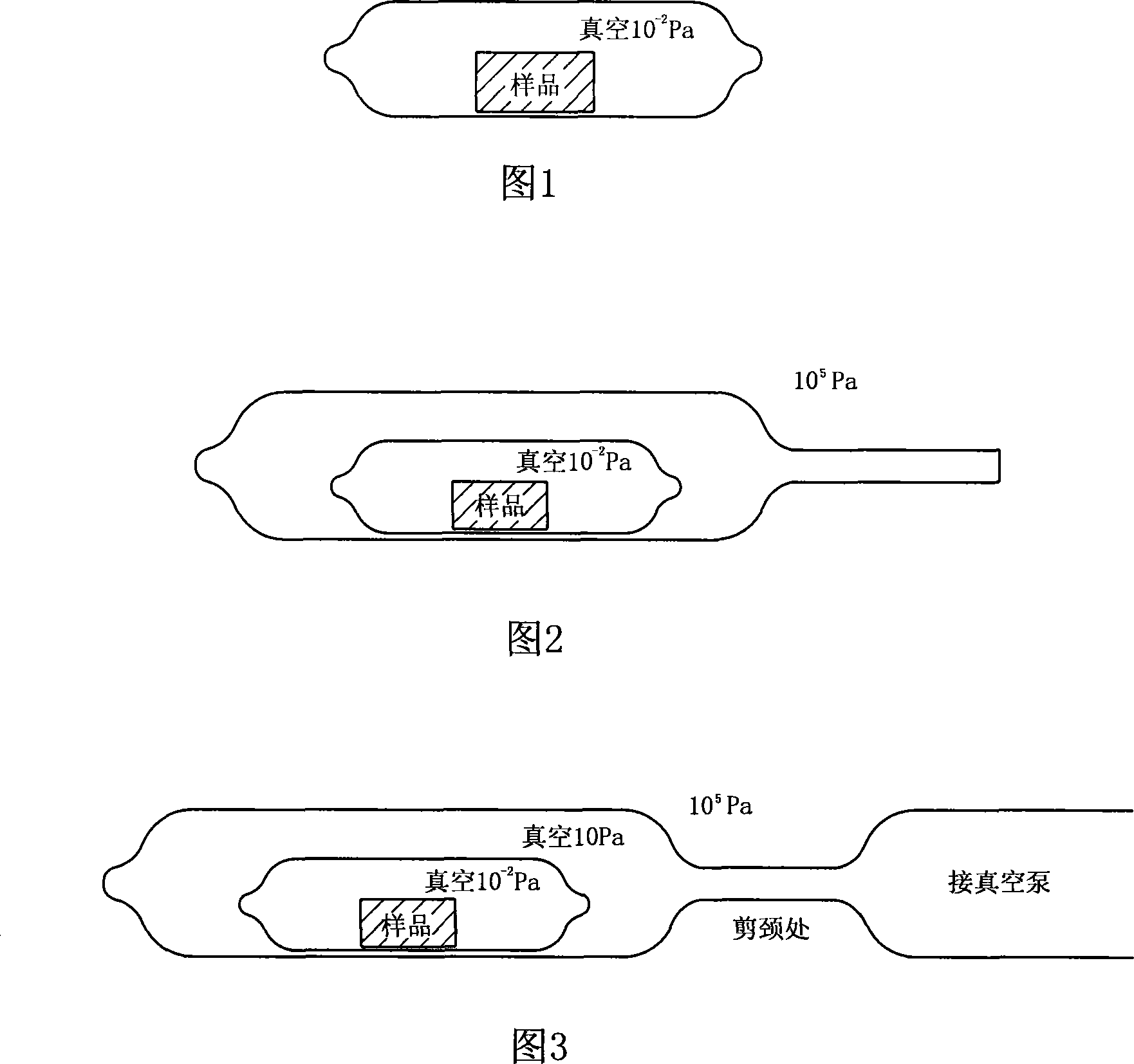

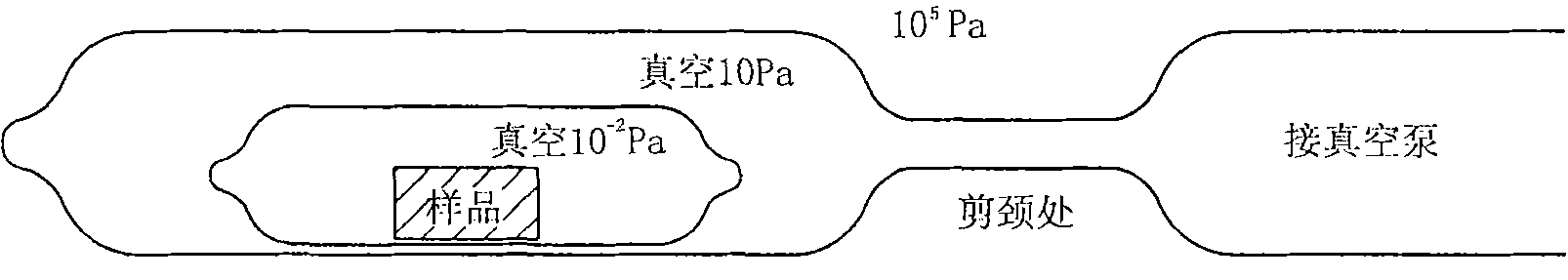

A technology for quartz tubes and samples, which is applied in the field of using double quartz tubes to prevent oxidation reactions of samples during heating, which can solve problems such as failure to prevent oxidation and leaks, reduce experimental costs, reduce experimental risks, and improve experimental results. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] In the determination of the Fe-Mn-Al system isothermal cross-sectional phase diagram test at 1300 °C, the sample was put into a double quartz tube and sealed according to the above experimental steps and methods, and then placed in a Si rod heating furnace with the temperature raised to 1300 °C for 3 hours. Afterwards, the sample was taken out and quenched in water. After the experiment, no Fe-Mn-Al sample was oxidized. The experimental results show that when the sample is heated at high temperature, the double quartz tube can be used to protect the sample from oxidation. The double quartz tube method can not only prevent the sample from , the whole experiment is very simple and easy to operate, and it also reduces the cost of the experiment, reduces the risk of the experiment, and improves the efficiency of the experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com