Hybrid vehicle drive device

A technology for a hybrid vehicle and a drive device, which is applied in the direction of a hybrid vehicle, a power device, an electric power device, etc., can solve the problems such as the reduction of the performance of the electric motor and the deterioration of the performance of the vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0028] Next, a first embodiment of the present invention will be described based on the drawings.

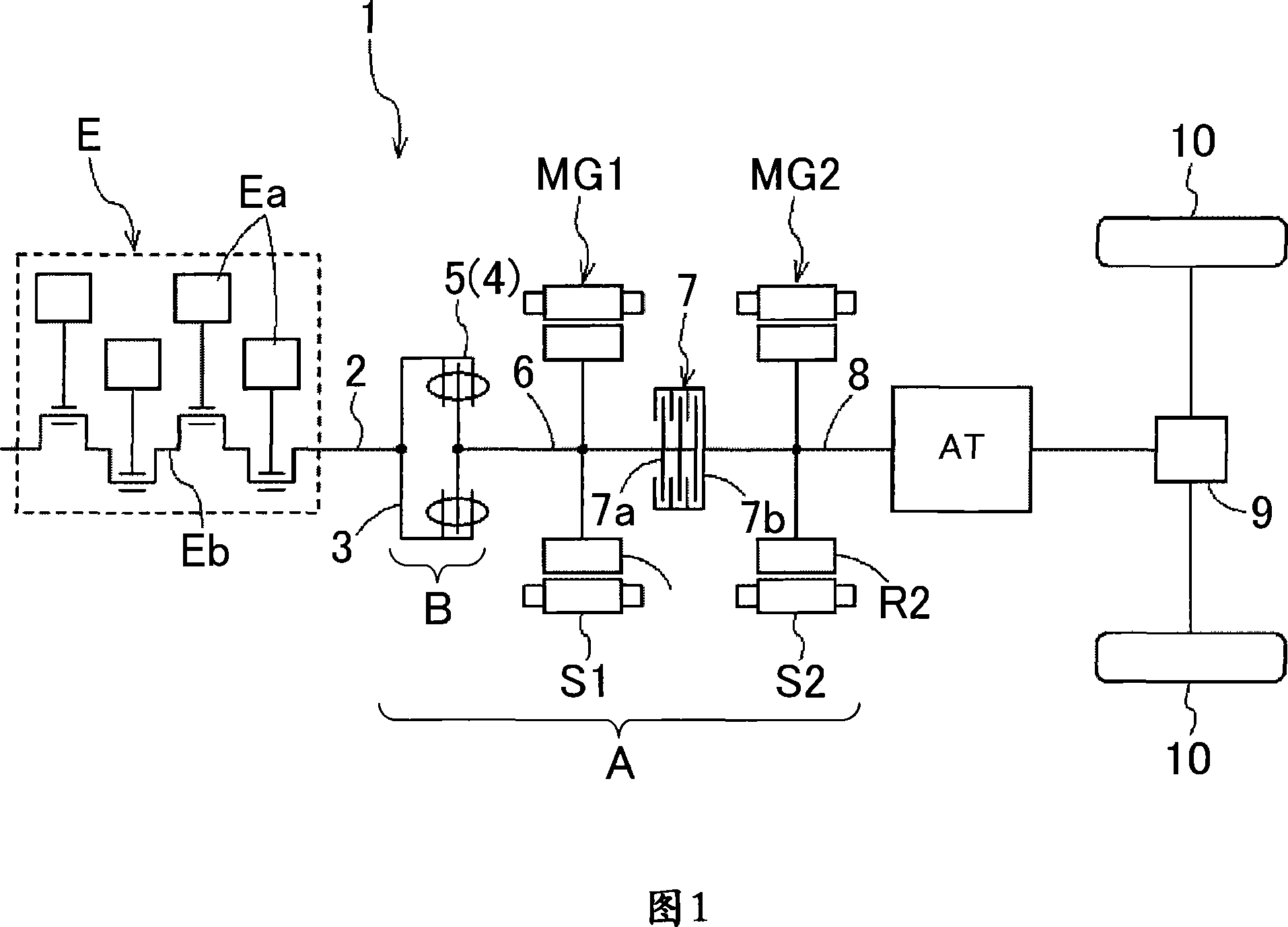

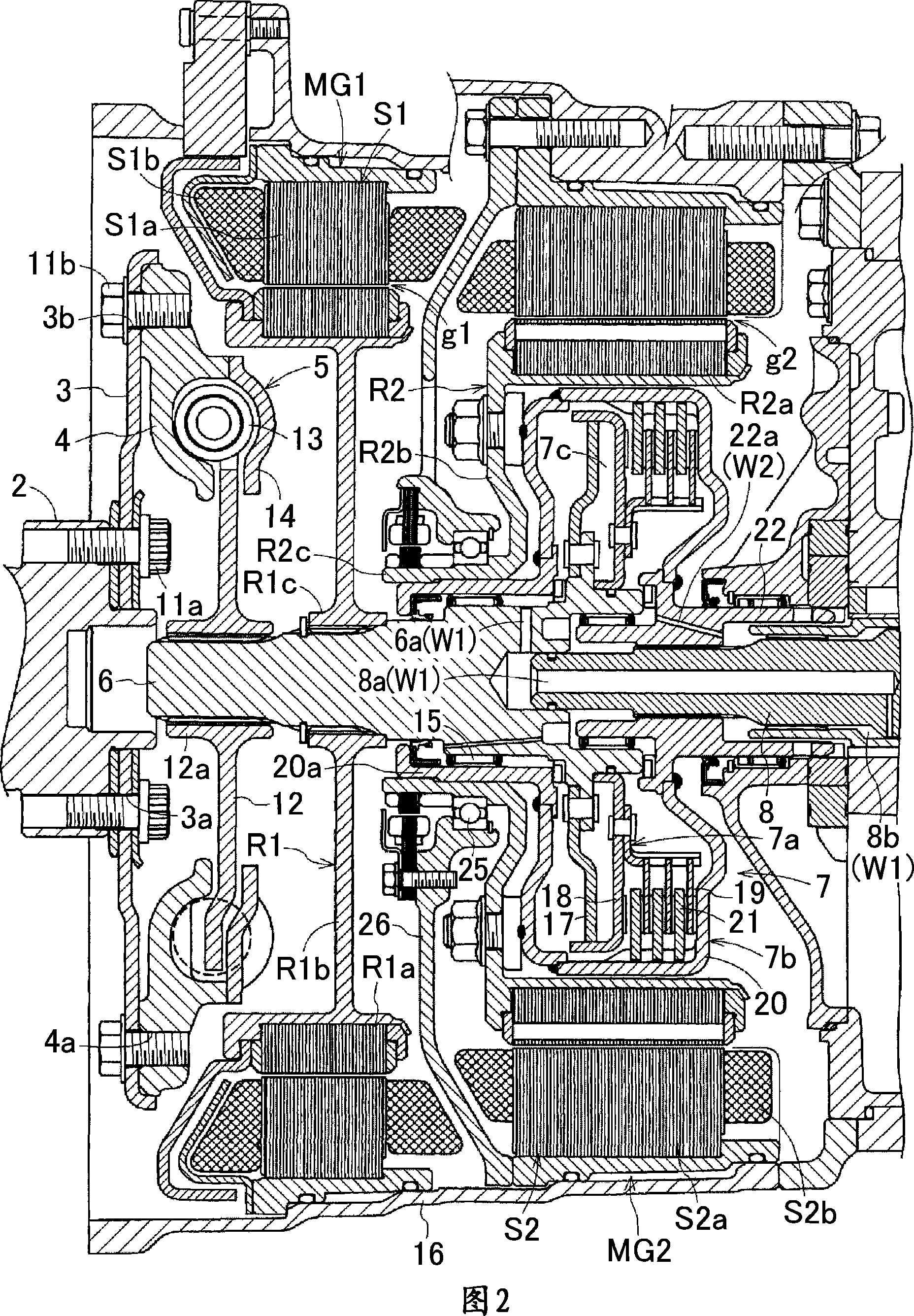

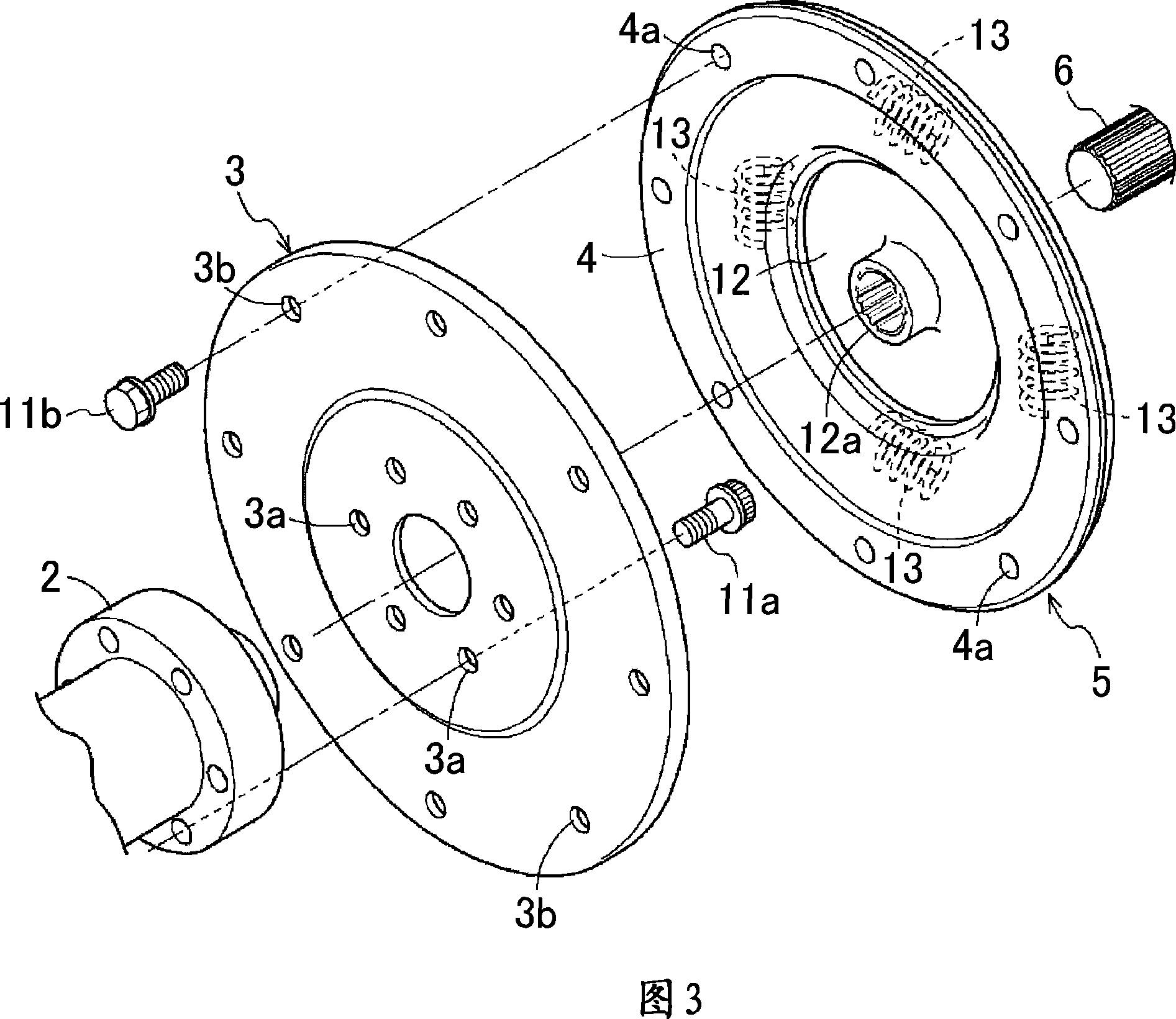

[0029] FIG. 1 is an explanatory diagram showing a schematic configuration of a drive device 1 for a hybrid vehicle according to the present embodiment. FIG. 2 is a cross-sectional view showing a specific configuration of part A in FIG. 1 . Fig. 3 is an exploded perspective view showing a specific configuration of part B in Fig. 1 .

[0030] As shown in FIG. 1 , a drive system 1 for a hybrid vehicle includes two motor / generators MG1 and MG2 between an engine E and an automatic transmission AT. Further, the driving device 1 for a hybrid vehicle, along the transmission path of the driving force from the engine output shaft 2 driven by the engine E, includes the driving disc 3, the damper 5 including the flywheel 4, the intermediate shaft 6, and the first motor. Sequential configuration of / generator MG1, clutch 7, second motor / generator MG2, transmission input shaft 8. The drivi...

no. 2 approach

[0061] Next, a driving device 1 for a hybrid vehicle according to a second embodiment of the present invention will be described. The schematic configuration of the drive device 1 for a hybrid vehicle according to this embodiment is the same as that of the first embodiment described above. FIG. 4 is a cross-sectional view showing a specific configuration of part A in FIG. 1 in the hybrid vehicle drive device 1 according to the present embodiment. As shown in the figure, the driving device 1 for a hybrid vehicle according to this embodiment differs from the above-described first embodiment in that the rotor R1 and the damper of the first motor / generator MG1 are integrally connected by a connecting member 23 . 5. The connecting member 23 is spline-engaged with the intermediate shaft 6 . In terms of other configurations, it can be made the same as that of the above-mentioned first embodiment.

[0062] In the present embodiment, the driven plate 12 of the damper 5 is provided wi...

Embodiment approach

[0066] (1) In each of the above-mentioned embodiments, the following structure has been described, that is, the drive plate 3 as a drive plate is connected to the transmission lower side of the engine output shaft 2, and the reducer equipped with the flywheel 4 is connected to the transmission lower side of the drive plate 3. The composition of vibrator 5. However, the scope of application of the present invention is not limited thereto. For example, the configuration of the transmission disc and the shock absorber 5 can also be exchanged, the shock absorber 5 is connected to the transmission lower side of the engine output shaft 2, and the transmission lower side of the shock absorber 5 is connected to the formation of the transmission disc, which is also One of the preferred embodiments. In such a case, the configuration of the transmission plate itself may be the same as that of the drive plate 3 in the above-mentioned first embodiment. But this time, on the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com