Water spraying device and cooling method for hot converter steelmaking slag

A technology of converter steelmaking and water spraying device, which is applied in the direction of recycling technology, etc., can solve problems such as uneven cooling, environmental pollution, and large water spraying volume, and achieve the effects of reducing cooling costs, avoiding environmental pollution, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] The invention provides a cooling method for hot converter steel-making slag. The specific solution is that the hot converter steel-making slag adopts an upper water spray system and a lower water spray system to spray water in layers, and adopts the method of intermittent water spray. cool down.

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

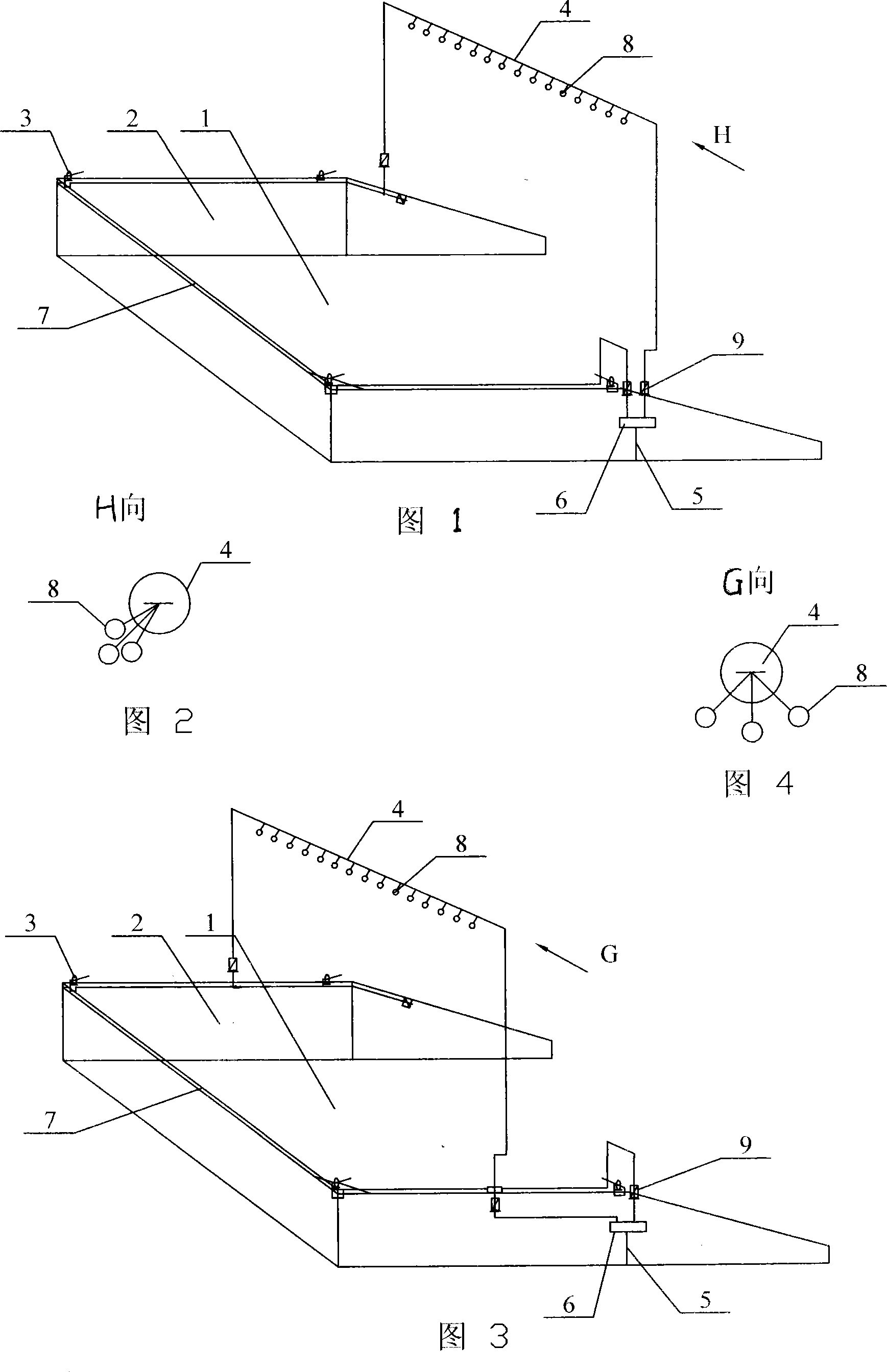

[0019] With reference to Fig. 1, Fig. 1 is the water spray device of hot state converter steelmaking slag, and it is the water spray device that cooperates the cooling method of the present invention and designs.

[0020] The above-mentioned water spraying device includes a slag box 1, a lower water spray system is arranged on the upper edge of the box wall 2 at the corner of the slag box 1, and an upper water spray system is arranged above the slag box 1 so that the spray water can cover the entire slag box 1 .

[0021] The lower water spr...

specific Embodiment approach 2

[0064] In this embodiment, the slag chamber is rectangular, and the water nozzles are four, and the four water nozzles are respectively arranged on the upper edge near the four corners of the wall of the slag chamber; the nozzles on the upper spray pipe are 30 One and set at the position directly above the slag box, referring to Figure 3, since the slag pouring operation is to be performed right above the slag box, it is necessary to set the water spray pipe as a mobile type, that is, install guide rails on the slag box for the upper water spray system Slip, move to the side during the slag-splashing operation, and then move to the middle to spray water after the slag-splashing operation.

[0065] The above-mentioned nozzles are divided into three groups and are respectively arranged in directions of 45, 90, and 135 degrees from the horizontal direction, referring to Figure 4, so that the cooling water can be evenly sprayed on the surface of the steel slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com