Hydraulic fill sand expansion polystyrene mixing light road bank stuffing filling and construction method

A technology of polystyrene particles and lightweight fillers is applied in the field of filling sand-filled expanded polystyrene particles mixed with lightweight embankment fillers. The effect of saving soil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

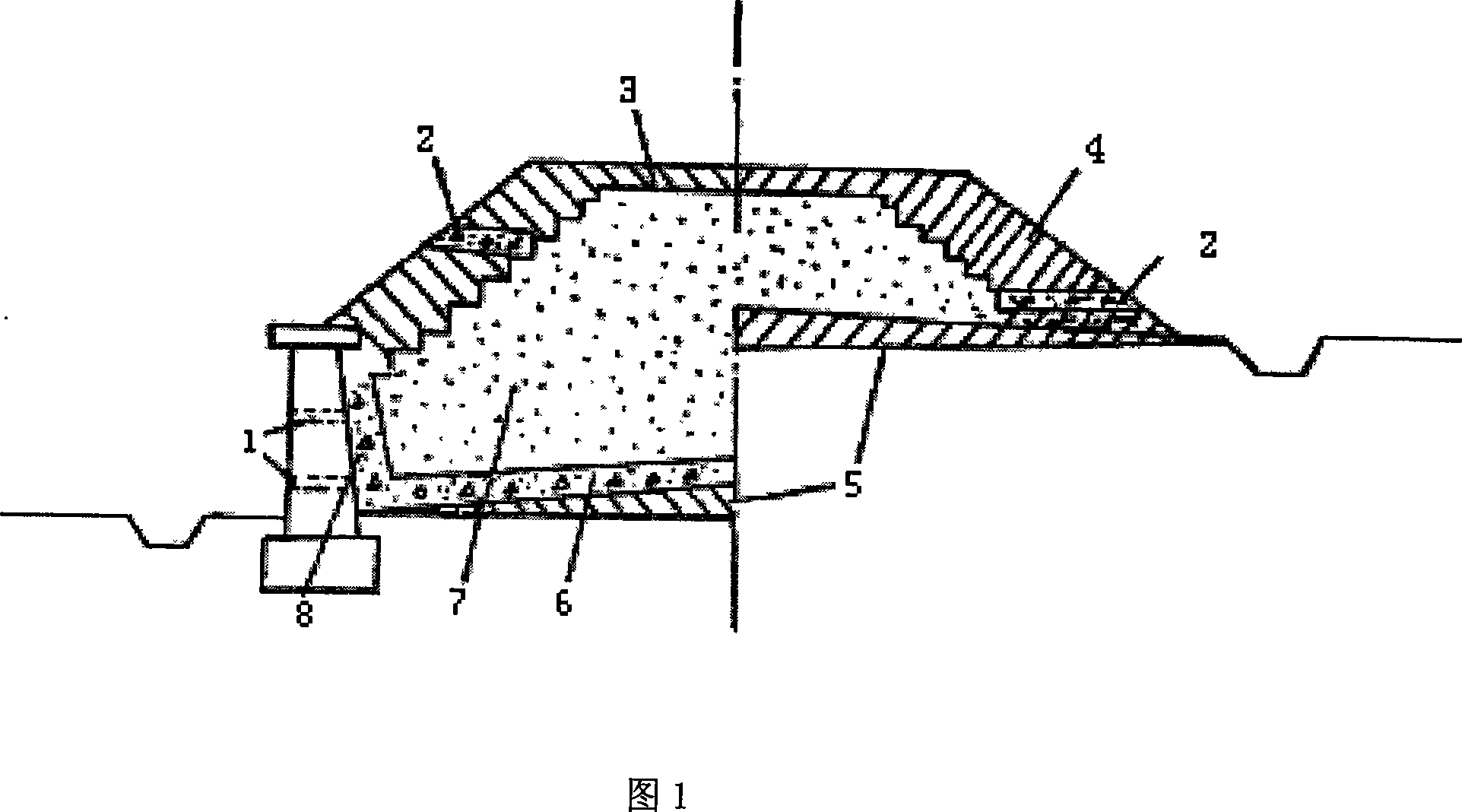

Image

Examples

Embodiment Construction

[0018] The specific operation is as follows:

[0019] a. Determine the particle gradation curve of dredging sand.

[0020] b. Prepare different dredging sand: EPS particle volume ratios, such as dredging sand: EPS volume ratio = 0.4: 0.6, 0.45: 0.55, 0.5: 0.5, 0.55: 0.45, 0.6: 0.4; then add different proportions of curing The mixing amount of the curing agent is 12%~20% of the weight of the dredging sand, and the compaction test is carried out after mixing with an appropriate amount of water, so as to obtain the maximum dryness of the mixed light materials with different proportions. Density and optimal moisture content.

[0021] c. Prepare samples according to the corresponding optimal water content and maximum dry density in step b, and measure the unconfined compressive strength for 7 days, 14 days and 28 days of curing.

[0022] d. Determine the proportion of mixed lightweight materials according to the strength and density requirements of different road embankment grade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com