Energy circulation device of spraying assembly line

An energy cycle and production line technology, applied in heat exchange equipment, fixed conduit components, heat exchanger types, etc., can solve problems such as energy waste, environmental thermal pollution, energy loss, etc., to reduce production costs, save energy, and eliminate the environment The effect of heat pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

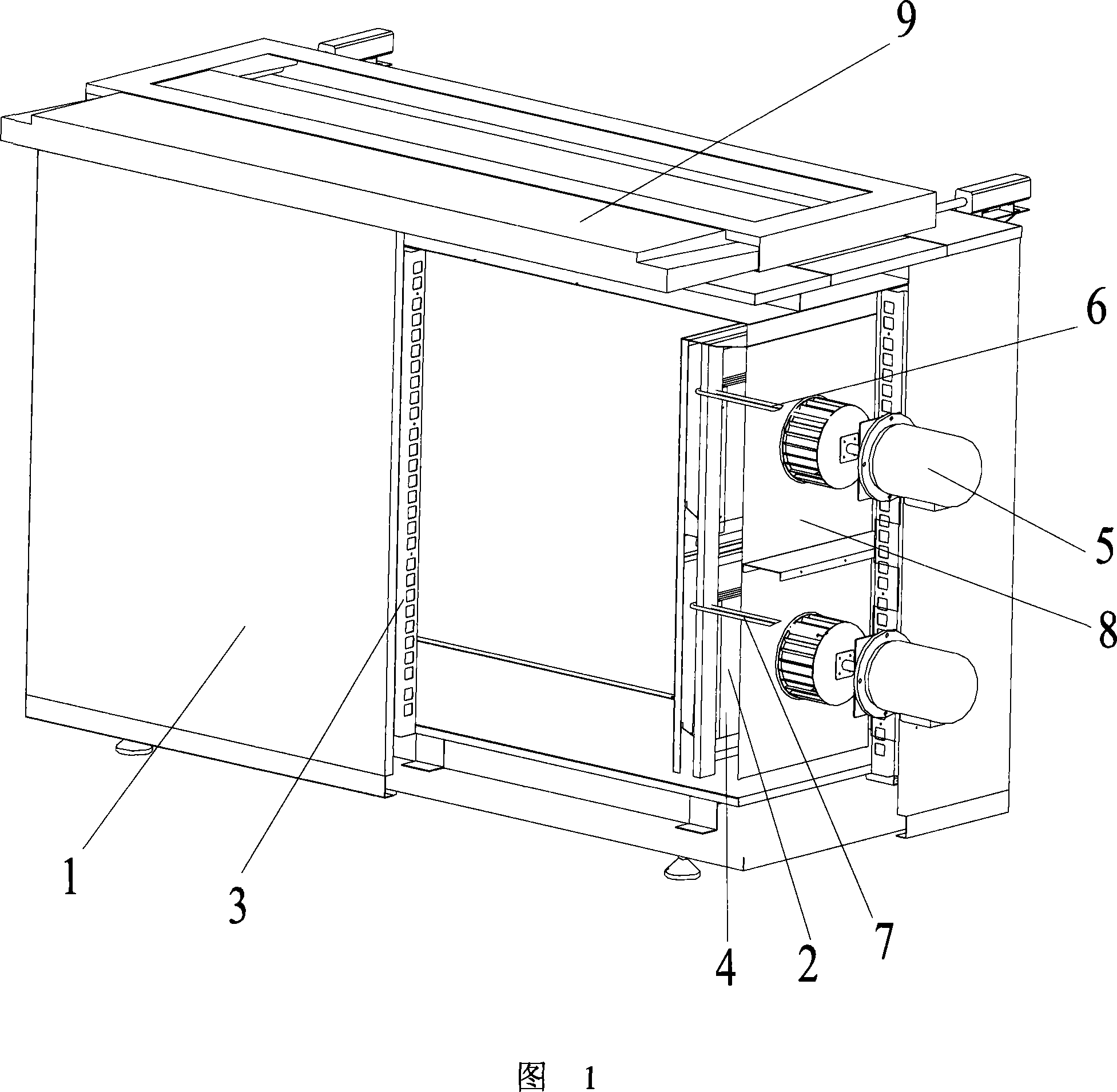

[0011] Embodiment: As shown in Figure 1, a kind of energy circulation device of spraying production line, comprises airtight box body 1 and the heat exchange device 2 in box body 1, and described box body 1 inner wall is provided with heat insulation layer 3, and described The heat exchange device 2 includes a heat exchanger 4 and a fan assembly 5, the heat exchanger 4 is a heat exchange coil, and the heat exchanger 4 is provided with a cooling medium inlet pipe 6 and a cooling medium outlet communicating with the outside of the box body 1 Tube 7.

[0012] The heat exchange device 2 is arranged on one side of the box body 1, the fan assembly 5 is arranged on the fan support frame 8 parallel to the side of the side box body 1, and the heat exchanger 4 is arranged on the side of the fan support frame 8. inside.

[0013] The heat exchanger 4 includes two blocks connected up and down, and the fan assembly 5 includes an upper fan and a lower fan corresponding to the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com