Battery with explosion prevention function

A battery and functional technology, applied in primary batteries, secondary battery manufacturing, battery pack components, etc., can solve the problems of not installing safety devices, explosion-proof covers that cannot be used for batteries, etc., to achieve convenient adjustment, good sealing, and overcome operation difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

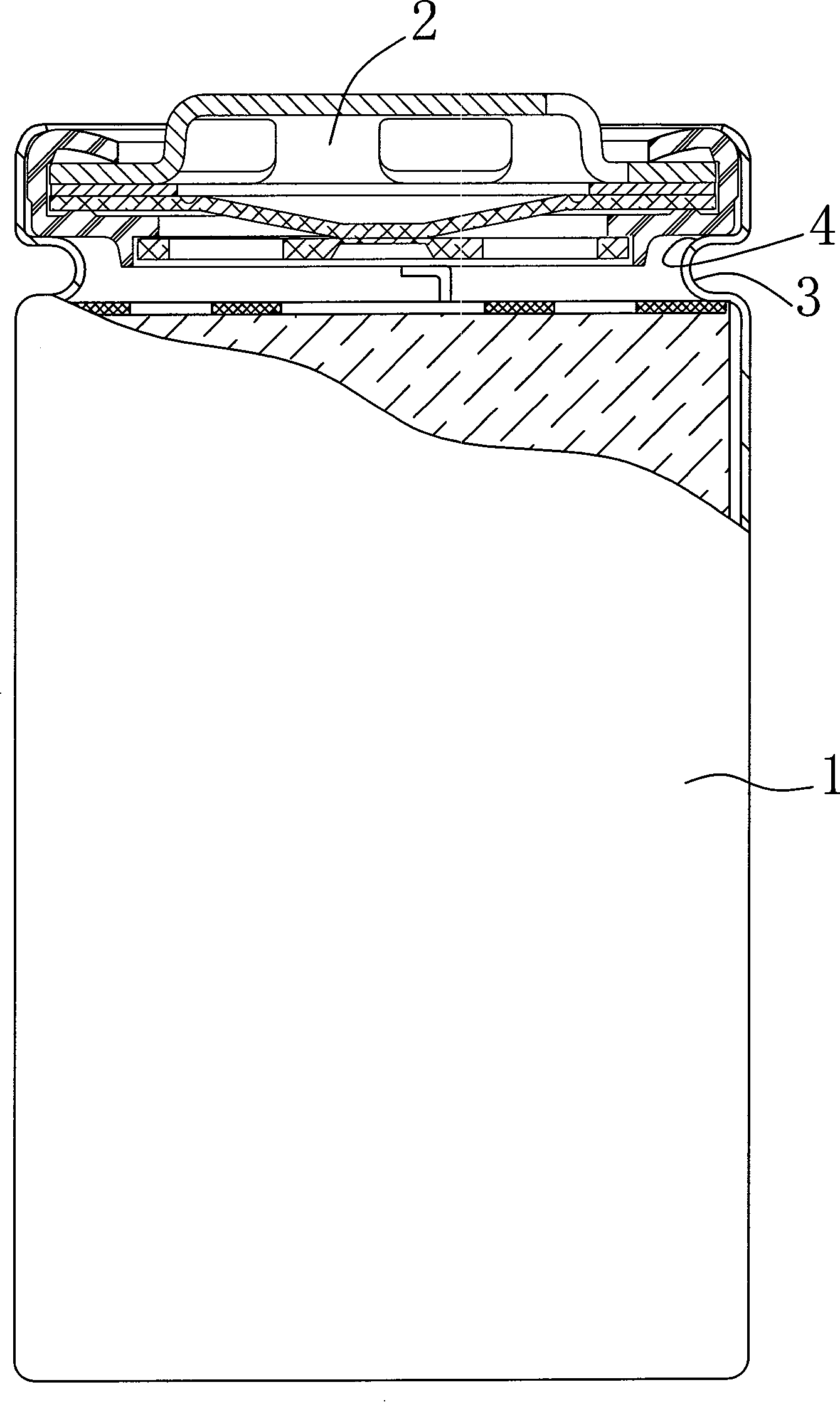

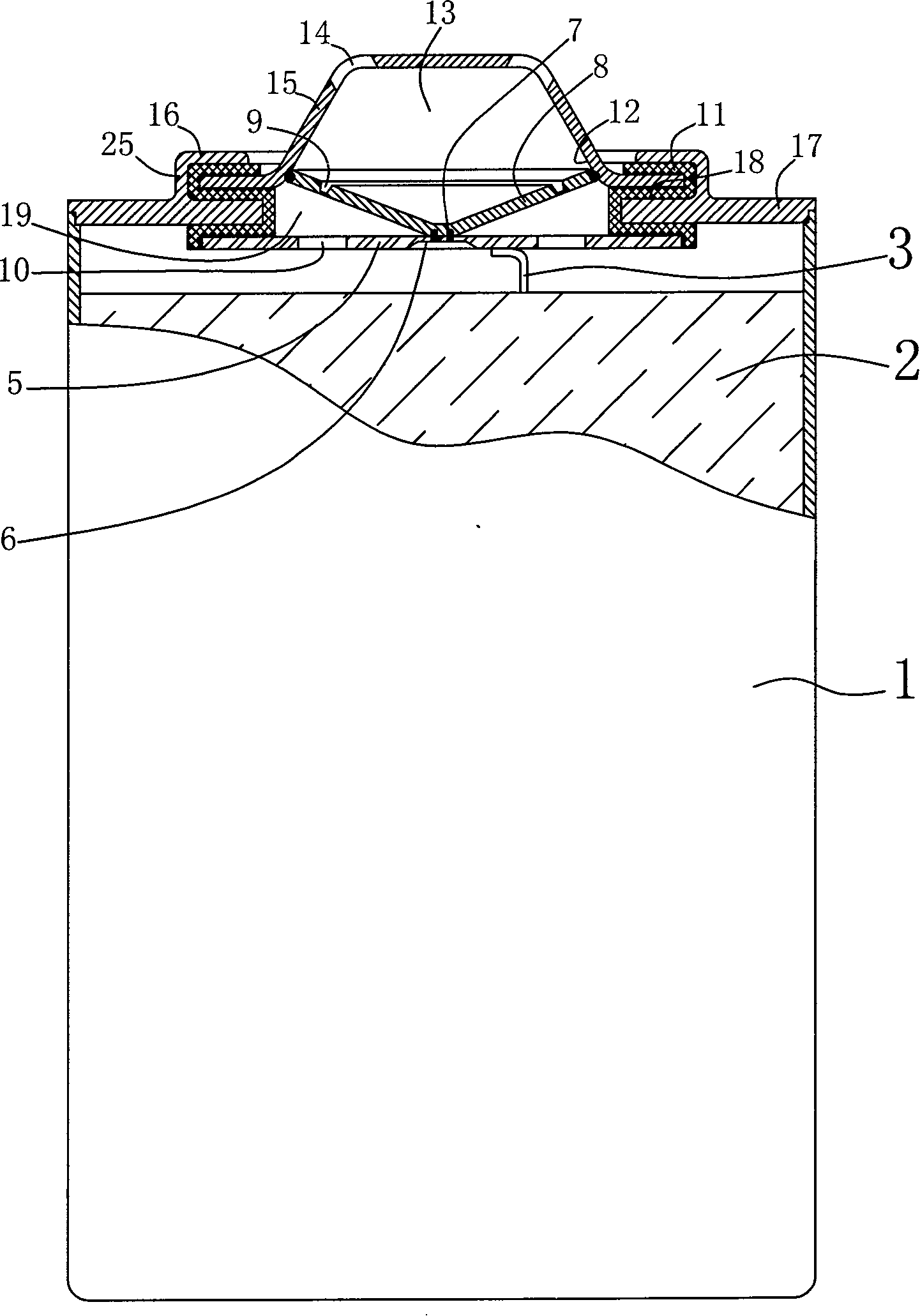

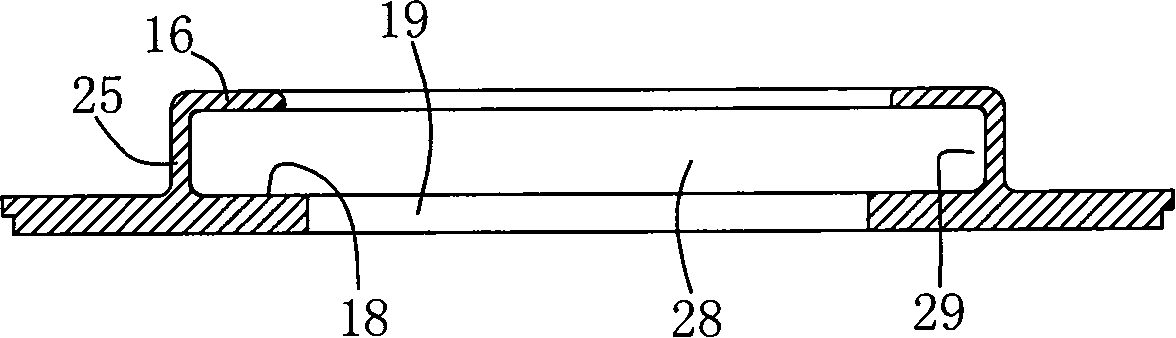

Embodiment 1

[0050] Embodiment 1. A battery combined with figure 2 , image 3As shown, it includes a battery container 1, an electrode assembly 2 accommodated in the battery container 1, and a cover plate assembly for sealing the battery container 1, wherein the cover plate assembly includes an assembly seat 17, a cover plate 15, an insulating member 11, and an explosion-proof film 8 and pull plate 5. The assembly seat 17 is an assembly plate welded on the battery container 1. The assembly plate has a cover plate hole 19, and there is an upwardly extending cylinder 25 around the cover plate hole 19, and a vertically connected cylinder 25 is formed in the cylinder 25. Cavity 28. There is an annular table top 18 around the cover plate hole 19 in the cylinder, and the upper part of the cylinder 25 forms an annular sealing groove 29 on the inner wall of the cavity 28 of the assembly seat 17 by bending inwardly (bending portion 16 ). There is a pressure relief hole 14 on the cover plate 15 ...

Embodiment 2

[0054] Embodiment 2, another kind of battery, combined with image 3 , Figure 6 As shown, it includes a battery container 1, an electrode assembly 2 accommodated in the battery container 1, and a cover plate assembly for sealing the battery container 1, wherein the cover plate assembly includes an assembly seat 17, a cover plate 15, an insulating member 11, and an explosion-proof film 8 and pull plate 5. The assembly seat 17 is an assembly plate welded on the battery container 1. The assembly plate has a cover plate hole 19, and there is an upwardly extending cylinder 25 around the cover plate hole 19, and a vertically connected cylinder 25 is formed in the cylinder 25. Cavity 28. There is an annular table top 18 around the cover plate hole 19 in the cylinder, and the upper part of the cylinder 25 forms an annular sealing groove 29 on the inner wall of the cavity 28 of the assembly seat 17 by bending inwardly (bending portion 16 ). There is a pressure relief hole 14 on the...

Embodiment 3

[0055] Embodiment 3, yet another battery, combined with Figure 7 and Figure 8 As shown, it includes a battery container 1, an electrode assembly 2 accommodated in the battery container 1, and a cover plate assembly for sealing the battery container 1, wherein the cover plate assembly includes an assembly seat 17, a cover plate 15, an insulating member 11, and an explosion-proof film 8 and pull plate 5. The assembly seat 17 is an assembly plate welded on the battery container 1, and the assembly plate has a cover plate hole 19, and a cylinder 25 extending downward is formed around the cover plate hole 19, and a vertically connected cylinder 25 is formed in the cylinder 25. Cavity 28. There is an annular table top 18 around the cover plate hole 19 in the cylinder, and the lower part of the cylinder 25 forms an annular sealing groove 29 on the inner wall of the cavity 28 of the assembly seat 17 by bending inwardly (bending portion 16 ). There is a pressure relief hole 14 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com