Modularized equipment hot-plugging module powering method and hot-plug control circuit

A control circuit, hot-swap technology, applied in electrical program control, emergency protection circuit devices, program control in sequence/logic controllers, etc., can solve problems such as large inrush current, reduce power waste, and improve the overall Reliability, the effect of improving the impact of inrush current on the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

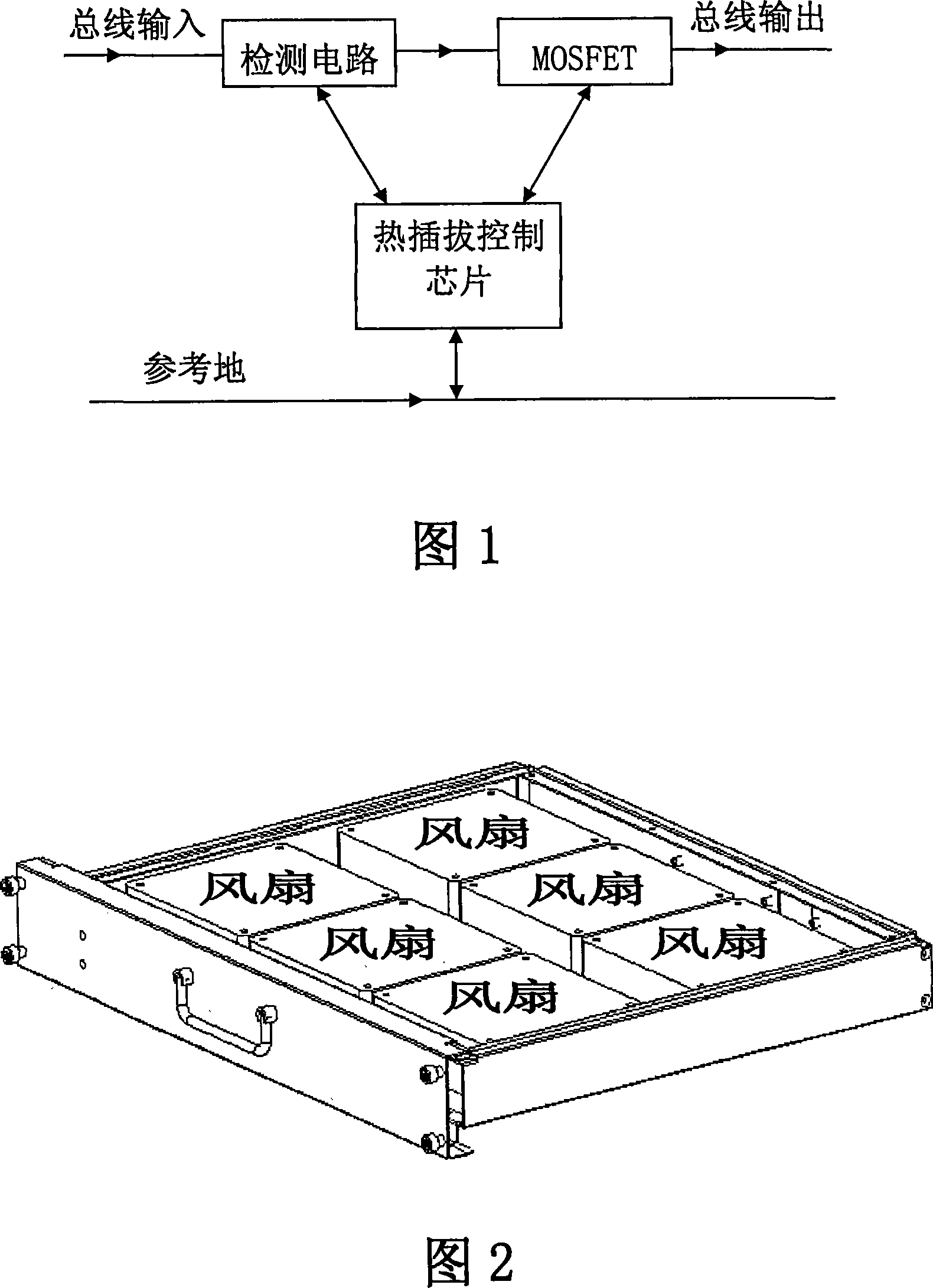

[0035] This embodiment provides a hot swap control circuit. In order to achieve the purpose of hierarchical power-on, the present invention improves the hot-swap control circuit of the module system of the modular equipment, and improves the control circuit that controls power-on by one hot-swap control chip to be controlled by multiple hot-swap control chips A control circuit that controls power-on. FIG. 3 is a schematic diagram of the hot swap control circuit when the fan modules of the modular switch are powered on in three stages according to this embodiment. As shown in Figure 3, the hot-swap control circuit includes: a three-stage hot-swap control unit, which is used to respectively control the three groups of fans of the hot-swap fan module to be powered on; and two delay circuits, the first delay The timing circuit is set between the first-level hot-swap control unit and the second-level hot-swap control unit, and is used to drive the second-level hot-swap control uni...

Embodiment 2

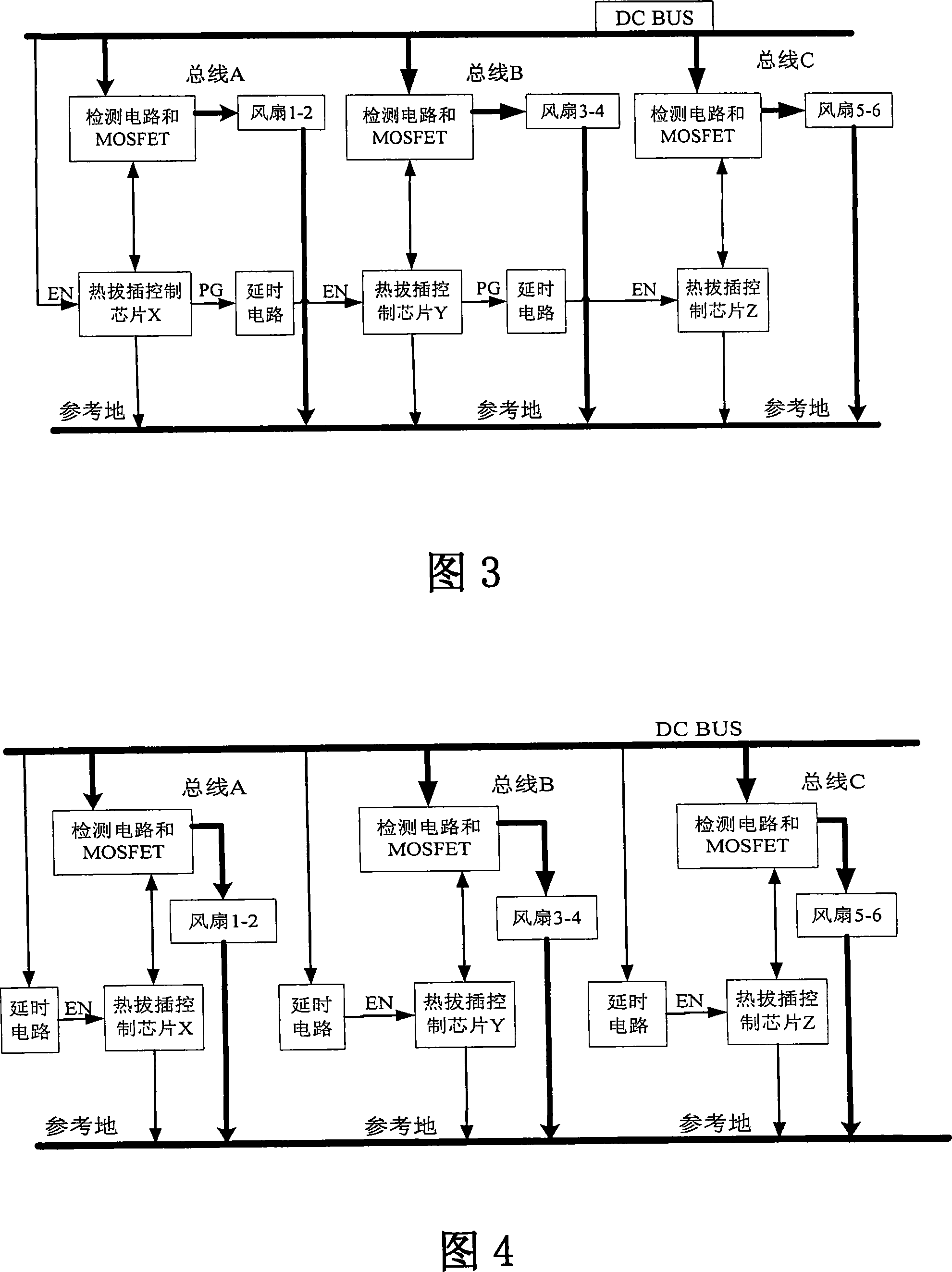

[0041] This embodiment further provides a hot swap control circuit. FIG. 4 is a schematic diagram of the hot swap control circuit when the fans of the fan module are powered on in three stages according to this embodiment. As shown in Figure 4, the hot-swap control circuit includes: a three-stage hot-swap control unit, which is used to control multiple groups of electrical equipment of the hot-swap module in parallel to power on; and three delay circuits, respectively connected The hot-swap control units at all levels are used to drive the hot-swap control units at all levels, and through different delays of the delay circuit, multiple groups of electrical equipment of the hot-swap module are powered on at different times. The delay circuit described in this embodiment is typically an RC circuit. If an accurate delay is desired, a classic delay circuit such as NE555 can be considered.

[0042] In this embodiment, the hot-swap control unit at each stage includes: a detection c...

Embodiment 3

[0047] This embodiment provides a hierarchical power-on method for hot-swappable modules in a modular device, and the method includes the following steps:

[0048] In the grouping step, the electrical equipment (such as fans) of the hot-swappable module is divided into multiple groups, and each group of electrical equipment is hung on different parts of the power supply bus (as shown in bus A, B, and C in Figure 3 and Figure 4) , or in other words, divide the bus of the modular device into several power-consuming parts. It is not very sensitive to delays in powering up between sections of the powered bus or between groups of powered devices.

[0049] In the staged power-on step, the corresponding multiple hot-swappable control units are used to control the multiple groups of electric equipment to be powered on at different times.

[0050] Taking a fan module with 6 fans as an example, the step-by-step power-on steps for implementing power-on in three stages include:

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com