Ball grid array packaging substrate for enhancing spherical washer fixation and ball grid array packaging structure

An array packaging and fixation technology, which is applied in the field of ball grid array packaging substrate and ball grid array packaging structure, can solve the problems of increasing the ball pad area, affecting the circuit configuration of the ball grid array packaging substrate, and being unable to apply to the ball grid array packaging substrate. , to achieve a strong fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

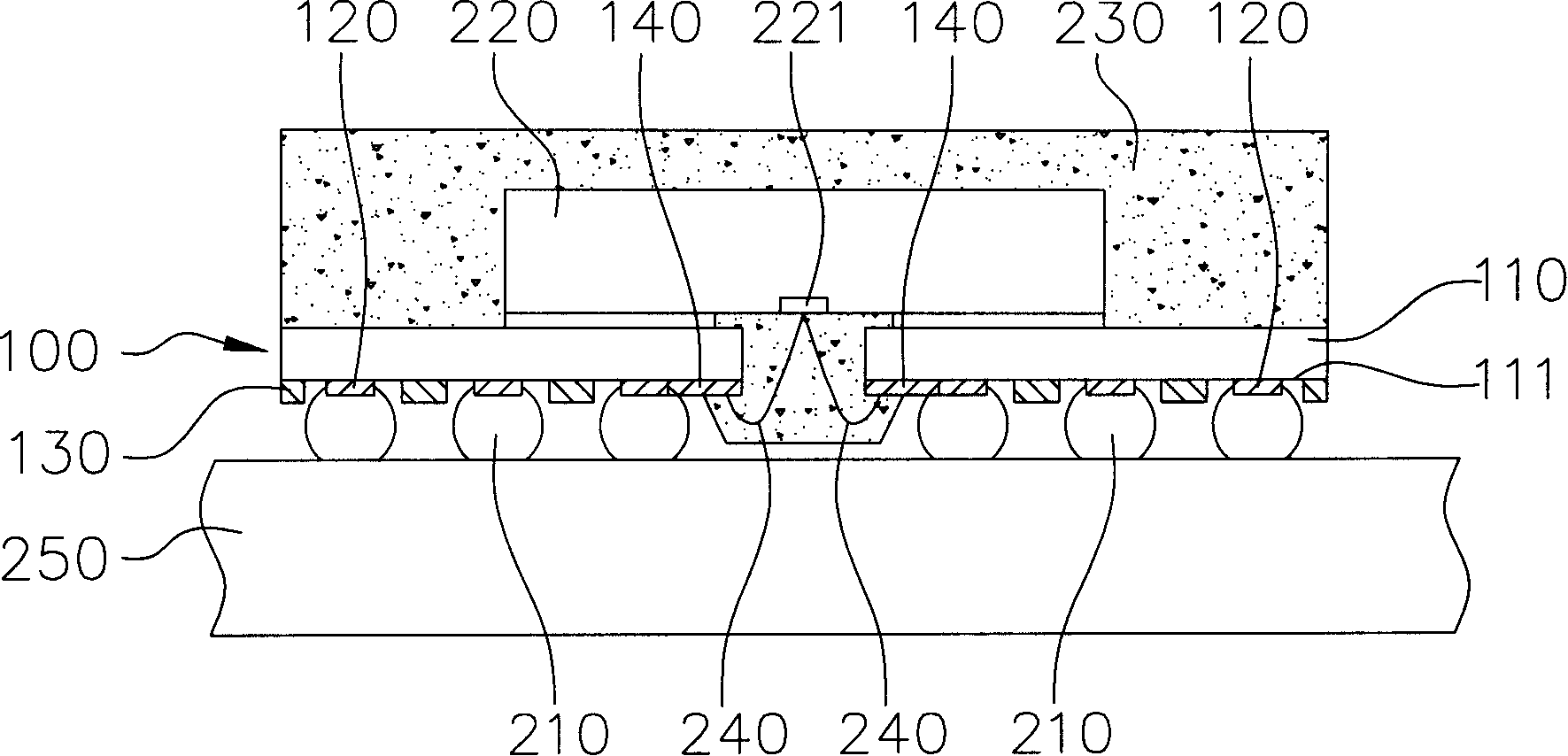

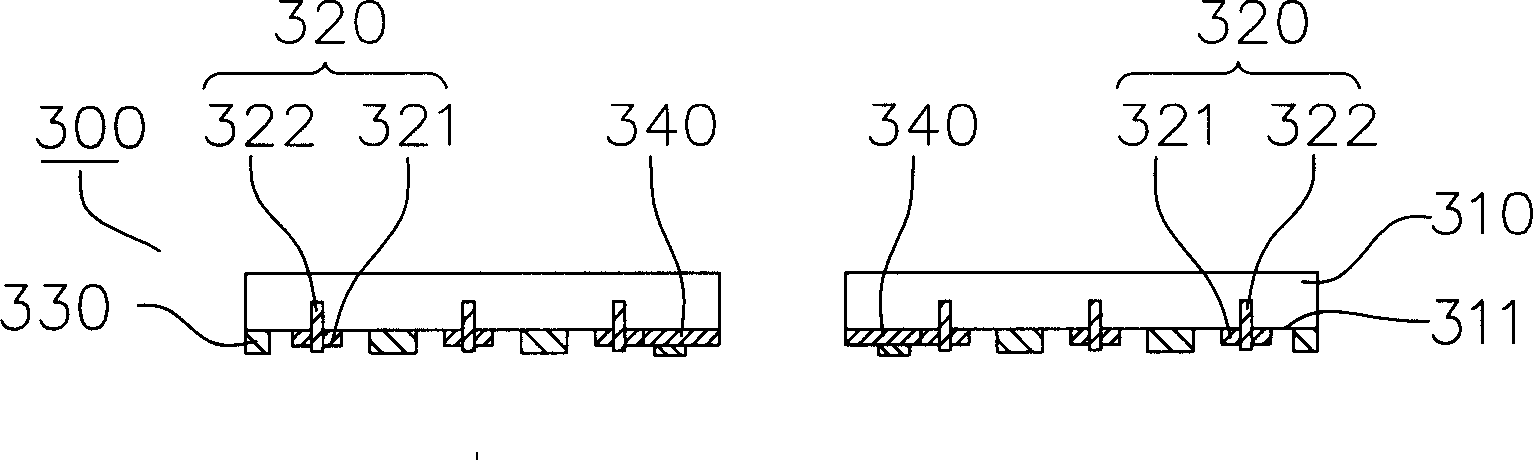

[0061] According to the first embodiment of the present invention, a ball grid array packaging substrate with enhanced ball pad fixation is disclosed, which is suitable for a chip carrier of semiconductor packaging. see image 3 Shown is a schematic cross-sectional view of a ball grid array packaging substrate that enhances the fixation of ball pads according to the first embodiment of the present invention. The BGA substrate 300 mainly includes a substrate core layer 310 , a plurality of ball pads 320 and a solder resist layer 330 . In this embodiment, the BGA substrate 300 has a single-layer wiring structure, which can be a printed circuit board, a ceramic carrier board or a circuit film. The arrangement of the ball pads 320 can be arrayed on the same surface of the substrate core layer 310 .

[0062] The substrate core layer 310 has a surface 311 on which circuits (not shown in the figure) can be arranged and a solder resist layer 330 is formed. Please refer to Figure ...

no. 2 Embodiment

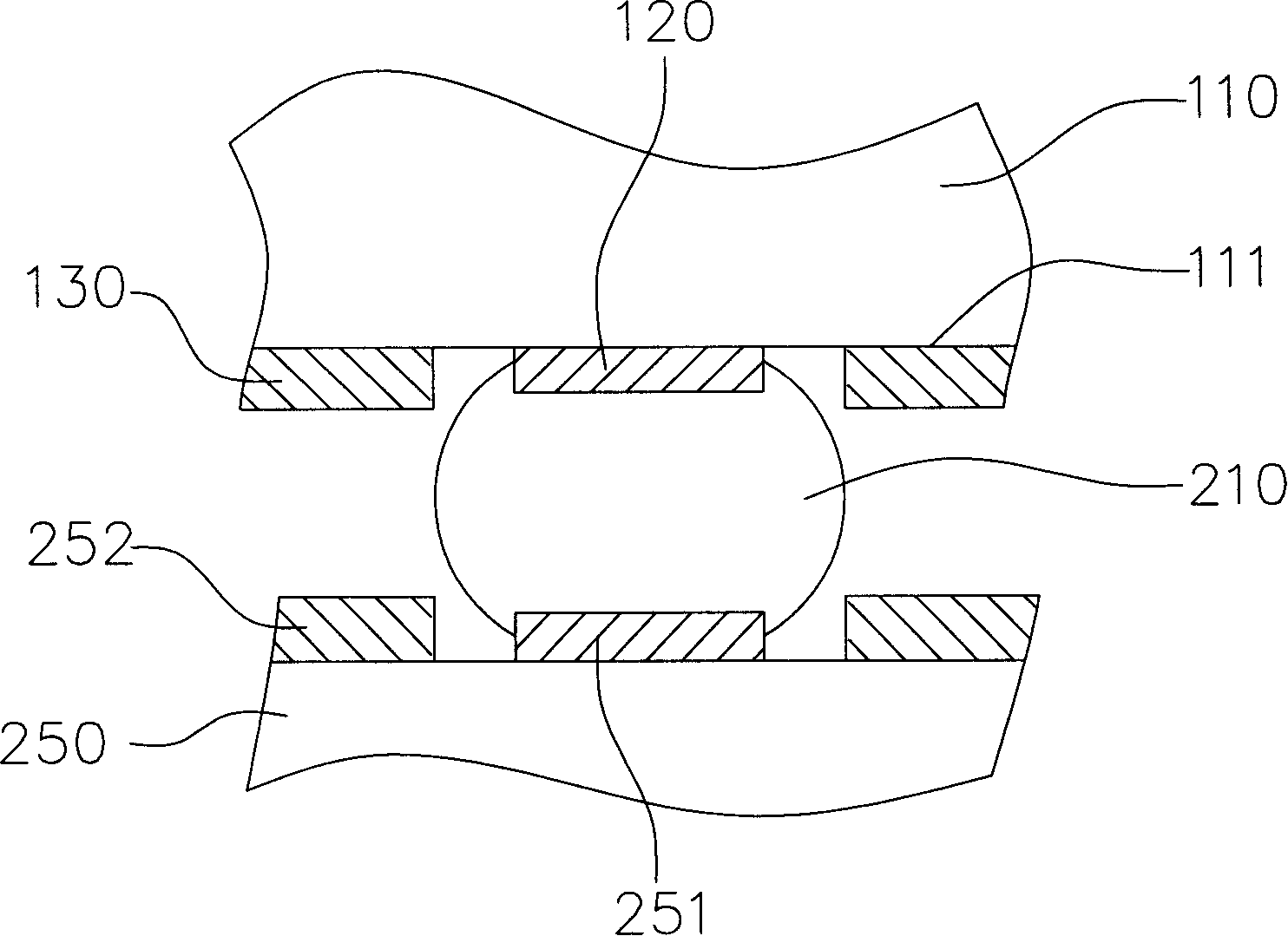

[0067] see Figure 6 As shown, the external printed circuit board 450 has a plurality of ball pads 451 exposed on the solder resist layer 452 thereof. The solder balls 410 bonded to the ball pads 320 are reflow bonded to the ball pads 451 . Since these ball pads 320 have strong fixation to the substrate core layer 310 and do not need to expand the area of the surface 311 occupying the substrate core layer 310, the bonding interface is not easily affected by external forces and has separation or cracks. In the second specific embodiment, another ball grid array packaging substrate with enhanced fixation of the ball pads is disclosed to illustrate that the ball pads with special shapes can be optionally disposed. see Figure 7 Shown is a schematic cross-sectional view of another ball grid array packaging substrate that enhances the fixation of ball pads according to the second embodiment of the present invention. The BGA substrate 500 includes at least one substrate core la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com