Mounting mechanism for vehicle and vehicle

An installation mechanism and vehicle technology, applied in the direction of vehicle springs, vehicle components, power units, etc., can solve the problems of high strength requirements of sheet metal body, unfavorable lightweight design of vehicles, and cost of the whole vehicle, so as to meet the requirements of lightweight design requirements, improve NVH performance, reduce the effect of manufacturing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

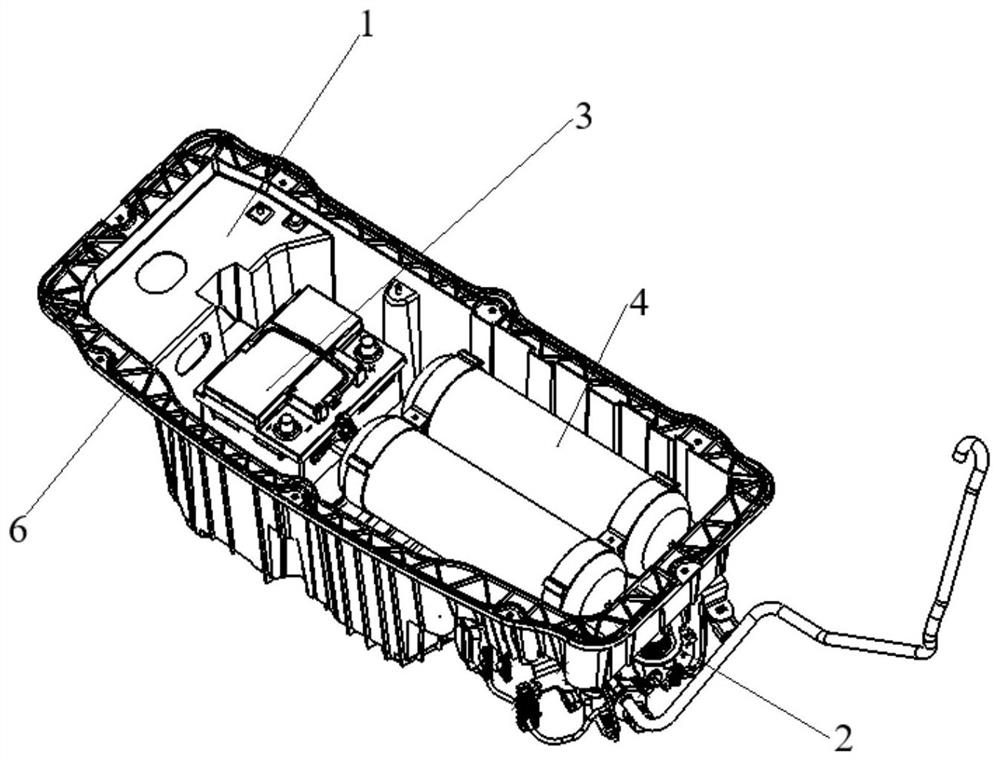

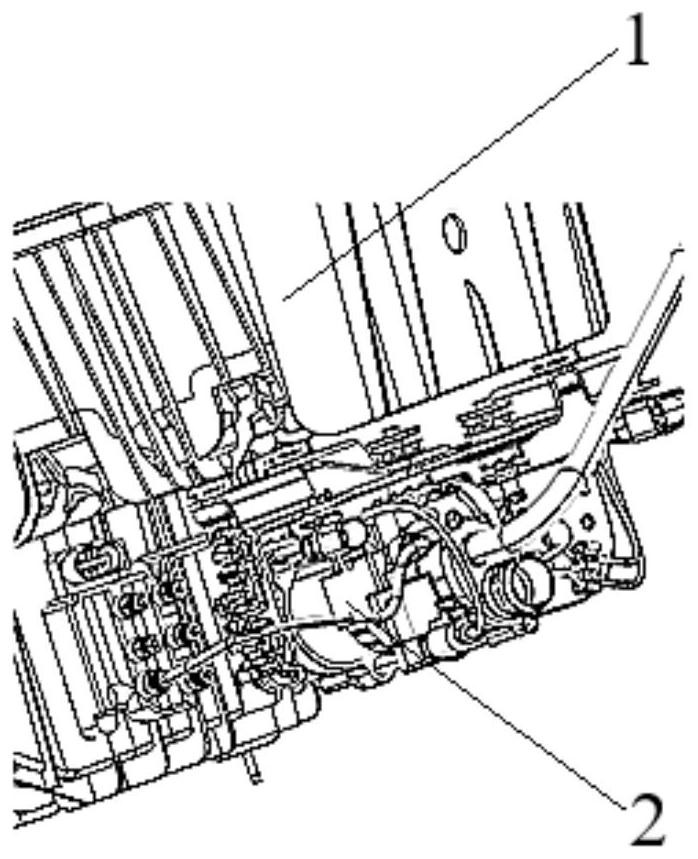

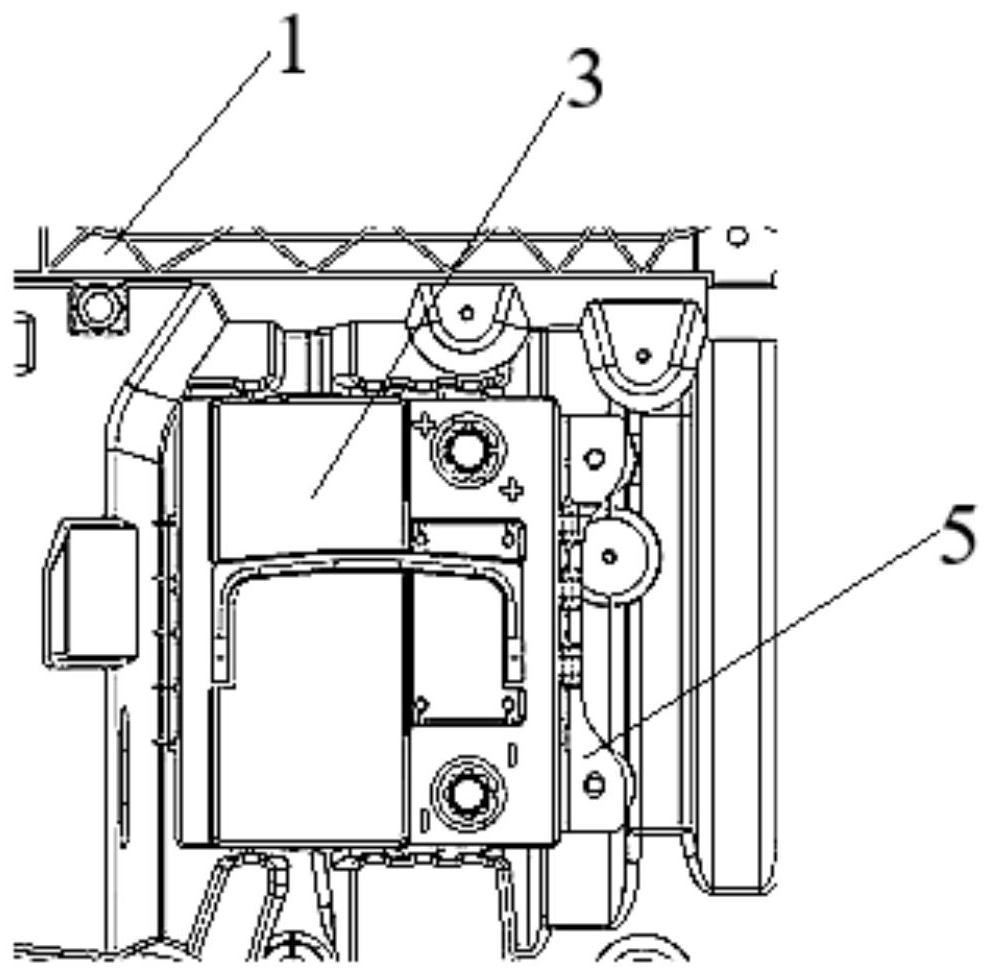

[0034] In this example, see Figure 1-6 , providing a mounting mechanism for a vehicle, comprising a box 1; the box 1 is arranged in the spare tire compartment of the vehicle, the box 1 is formed of a plastic composite material, the box 1 has a receiving space and an opening at the top, the box The bottom of 1 includes a first bottom and a second bottom arranged along the length direction of the box body 1 , the first bottom is higher than the second bottom, and an air suspension air pump 2 is fixedly connected to the outside of the first bottom. The air suspension air pump in the prior art is fixed on the sheet metal body, and the sheet metal needs to be strengthened to reduce the vibration of the air suspension air pump. In this embodiment, the air suspension air pump is fixed on the box made of plastic material. Compared with sheet metal materials, plastic composite materials have good elasticity characteristics and have obvious advantages in reducing vibration transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com