Timepiece component and timepiece having the timepiece component

A technology for watches and components, which is applied in the field of watch components, can solve the problems that the wear resistance and lubricity cannot be imparted, and the surface of the composite coating cannot be smoothed, etc., and achieve the effect of small friction coefficient and improved lubricity and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] (The overall structure of electronically controlled mechanical clocks)

[0040] Embodiments of the present invention will be described below with reference to the drawings.

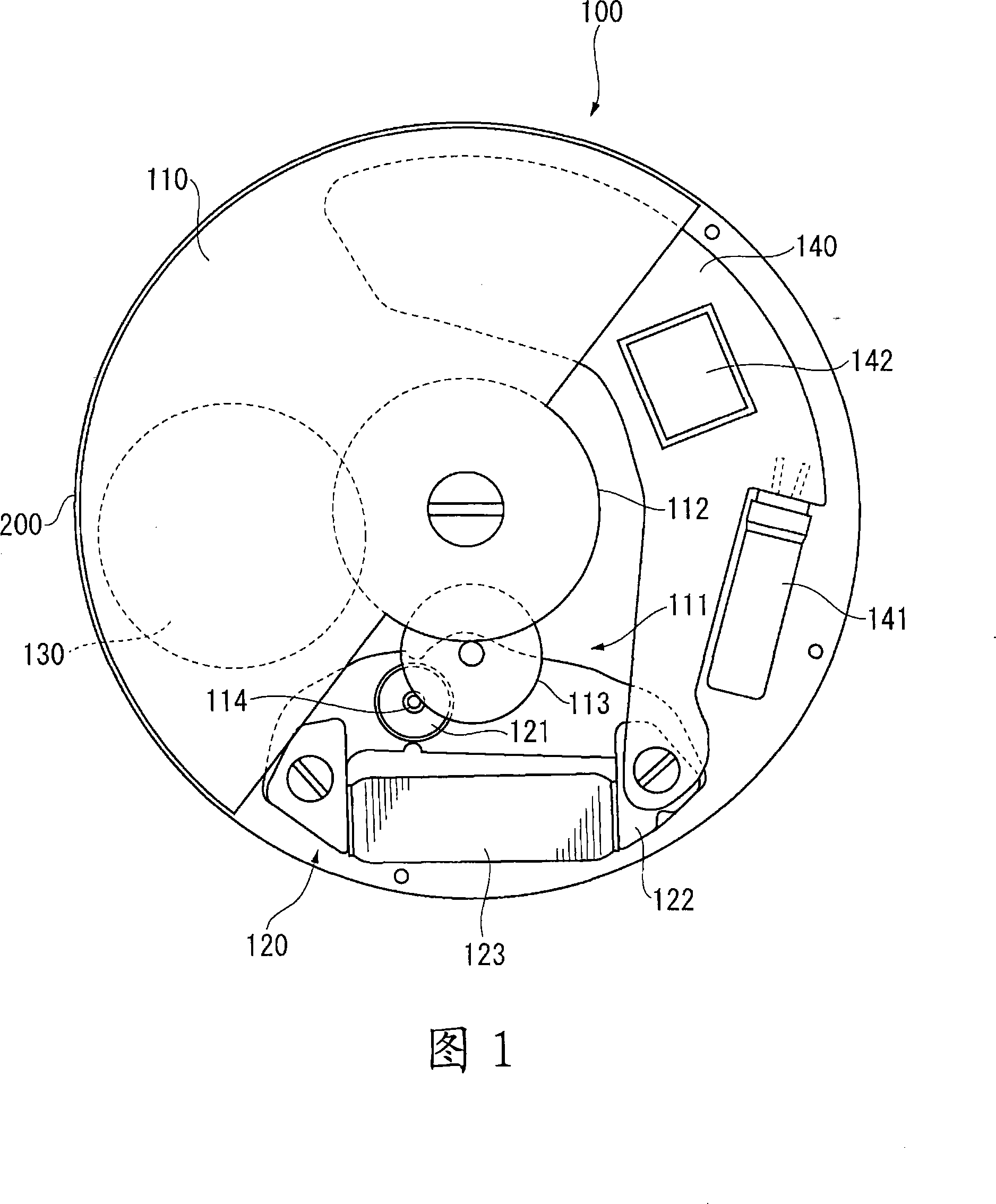

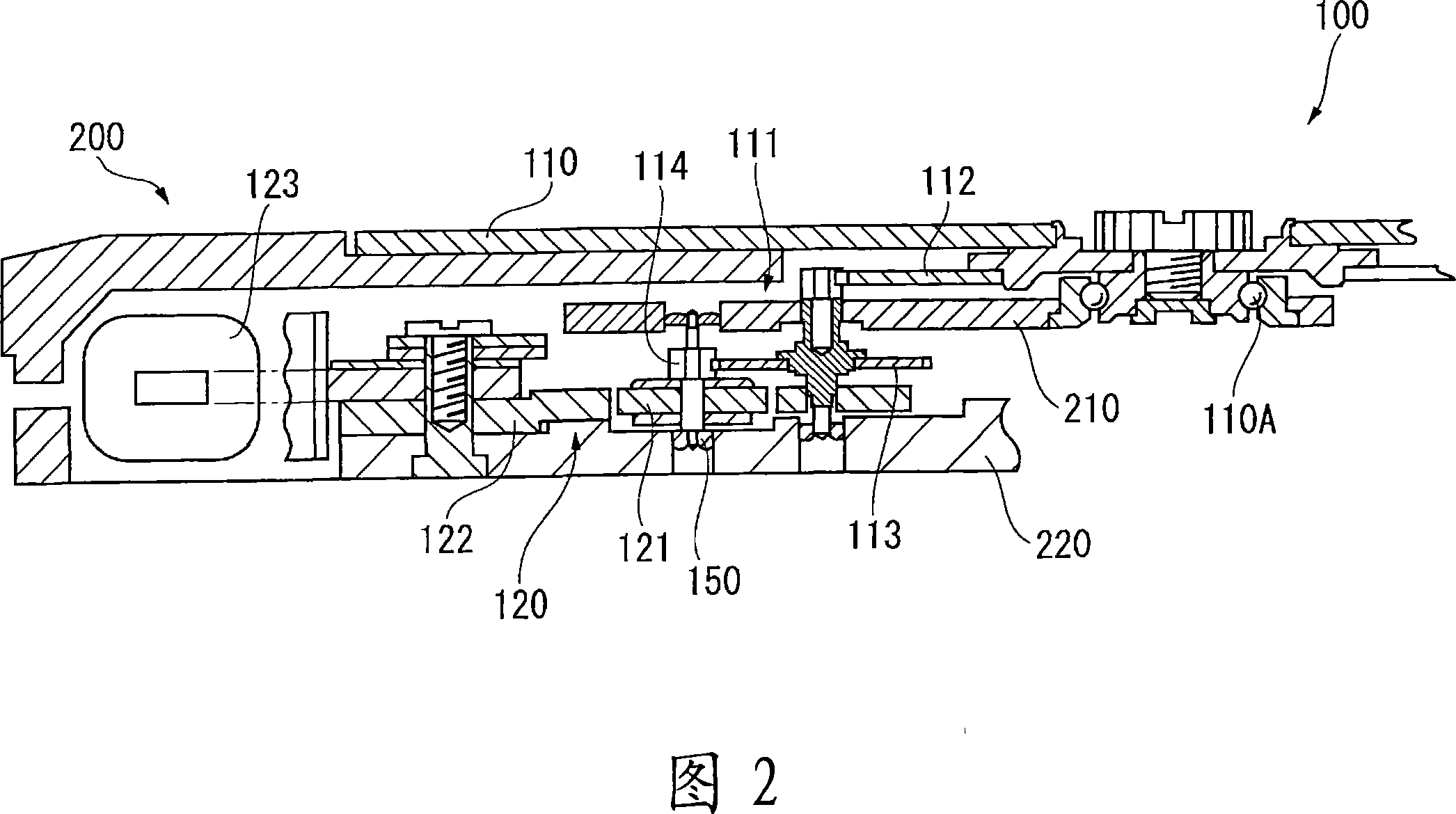

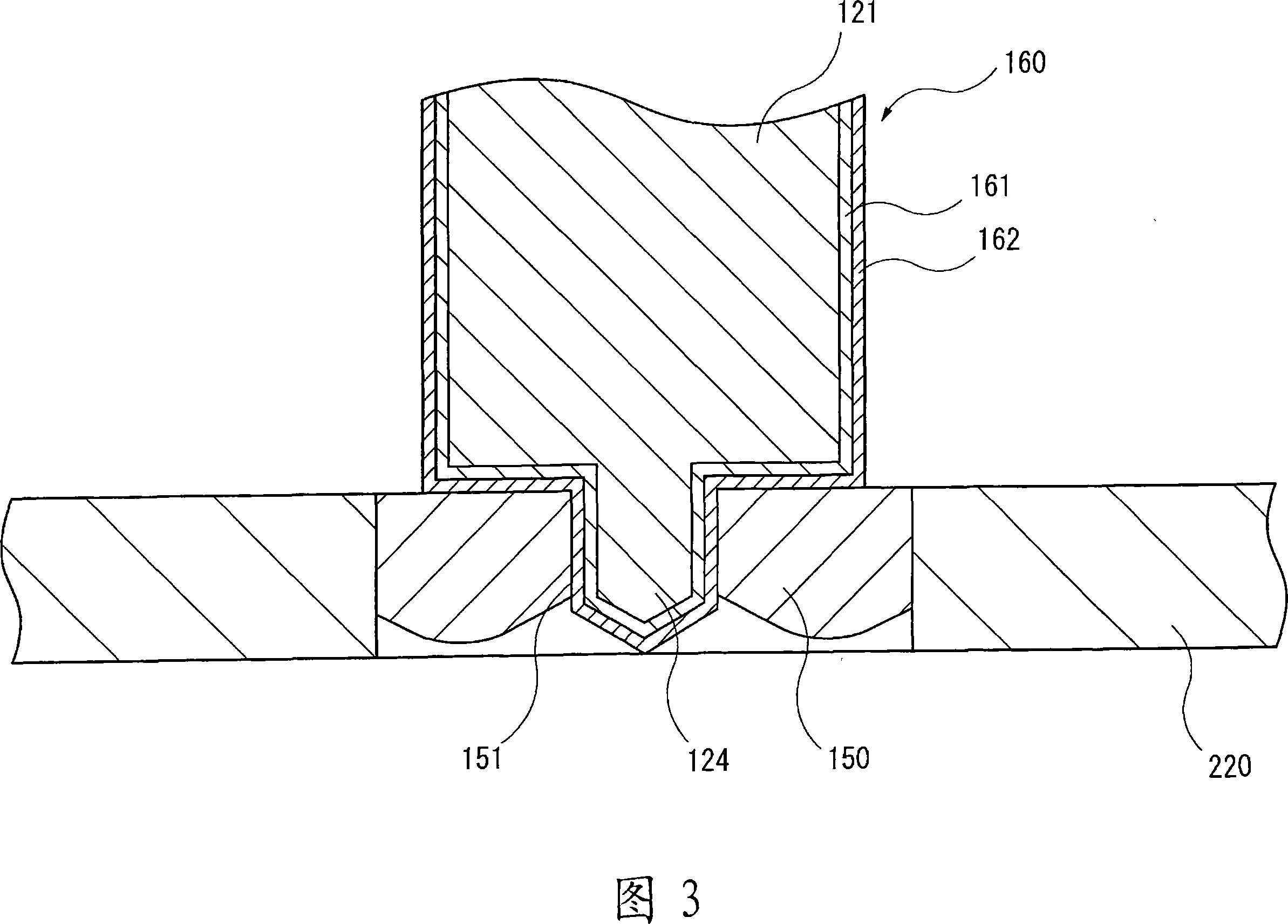

[0041] FIG. 1 is a schematic plan view of a timepiece 100 according to this embodiment, and FIG. 2 is a partial sectional view of the timepiece 100 . In the present embodiment, the timepiece 100 is a wristwatch having a structure in which generated power is obtained by rotation of a rotary weight when the wrist is moved, and a secondary battery is charged with the generated power. In FIG. 1 and FIG. 2 , the timepiece 100 has: a rotary weight 110; a speed-increasing gear train 111 that transmits the speed-up of the rotation of the rotary weight 110; a generator 120 that generates electricity through the rotation of the rotary weight 110; The secondary battery 130 in which the electric power generated in 120 is stored; and the circuit module 140 driven by the electric power generated by the generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com