Fixation method of cylinder head airway core

A fixing method and airway core technology, applied in cores, casting molding equipment, casting molds, etc., can solve problems such as waste loss, reduce waste loss, improve airway dimensional accuracy, and improve product quality and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

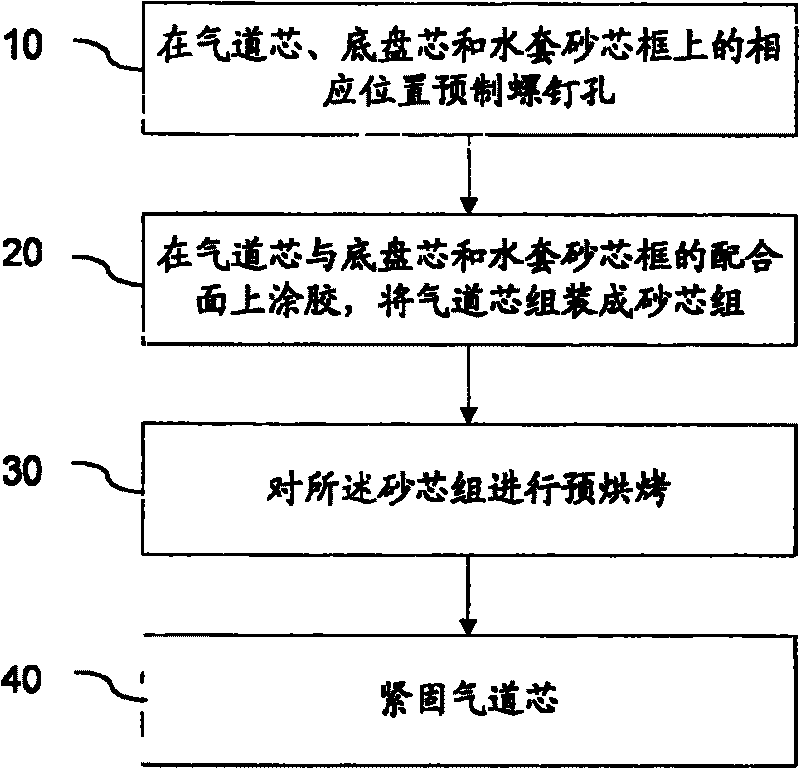

[0033] figure 1 It is a flow chart of the method for fixing the cylinder head airway core of the present invention, including steps:

[0034] Step 10, prefabricating screw holes at corresponding positions on the airway core, chassis core and water jacket sand core frame;

[0035] Step 20, apply glue on the mating surfaces of the airway core, the chassis core and the water jacket sand core frame, and assemble the airway core into a sand core group;

[0036] Step 30, pre-baking the sand core group;

[0037] Step 40, fastening the airway core.

[0038] The above technical solution of the present invention breaks through the traditional process of "fixing the airway square core head", and proposes a technical solution for completely fixing the airway core. The technical solution of the present invention realizes the fixation of the airway core through the process of prefabricated hole-gluing-baking-fastening, which can not only completely solve the problem of the floating of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com