Multiple eccentric shaft processing method and using counterbalance and eccentric sleeve

A processing method and eccentric shaft technology, which can be applied to eccentric shafts, counterweights, manufacturing tools, etc., can solve the problem that the process does not have a good processing method, and achieve the effects of convenient and fast production, high precision and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

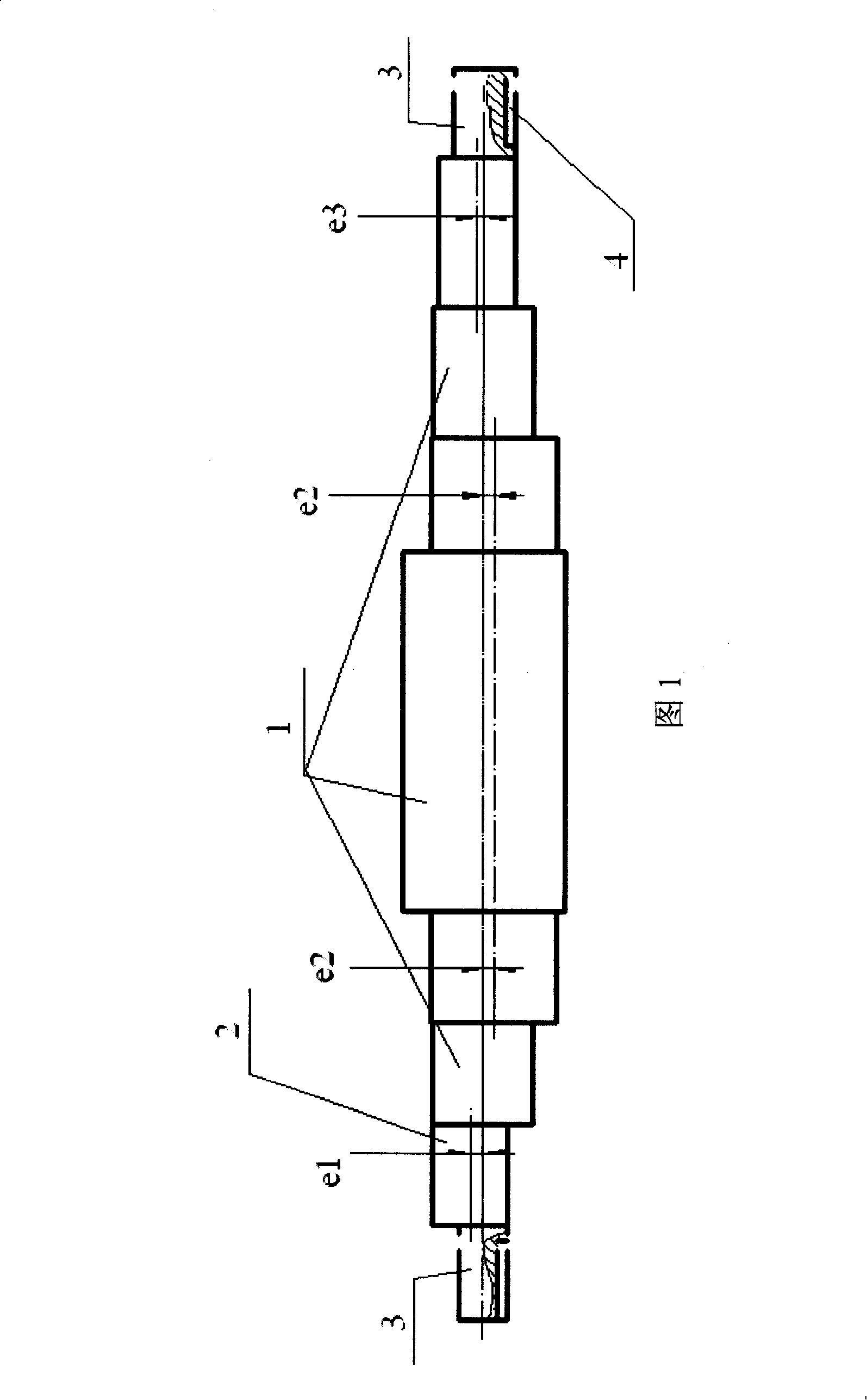

[0022] The processing method of many eccentric shafts of the present invention is shown in Fig. 1, and the method comprises the steps:

[0023] (1) Set the reference axis of the multi-eccentric shaft. The part where the axis and the reference axis coincide is the reference gear 1, and the part that does not overlap is the eccentric gear 2. The distance between the axis of the eccentric gear and the reference axis is the eccentricity, as shown in Figure 1 It shows that different eccentric gears have different eccentric distances e1, e2, e3;

[0024] (2) Extended ends 3 are respectively arranged at both ends of the multi-eccentric shaft, and the axis of the extended end 3 coincides with the reference axis;

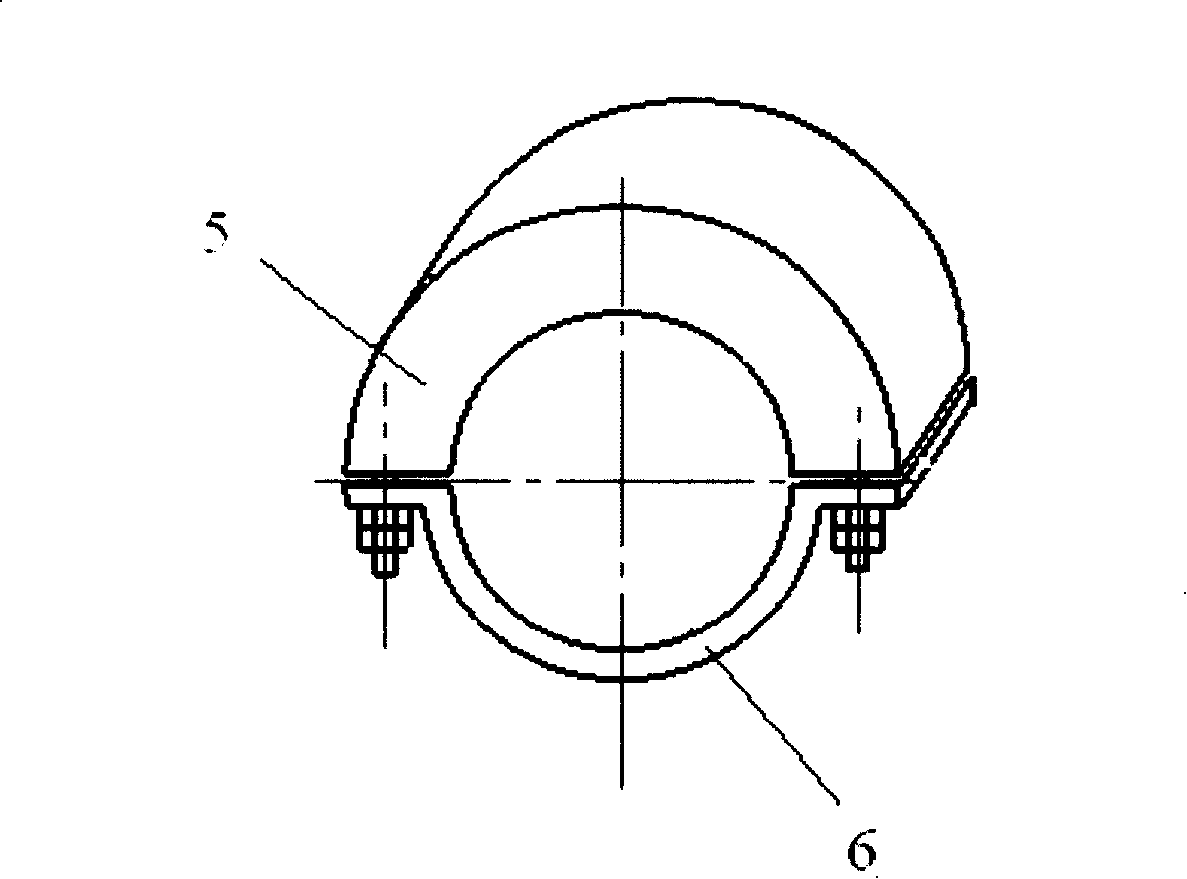

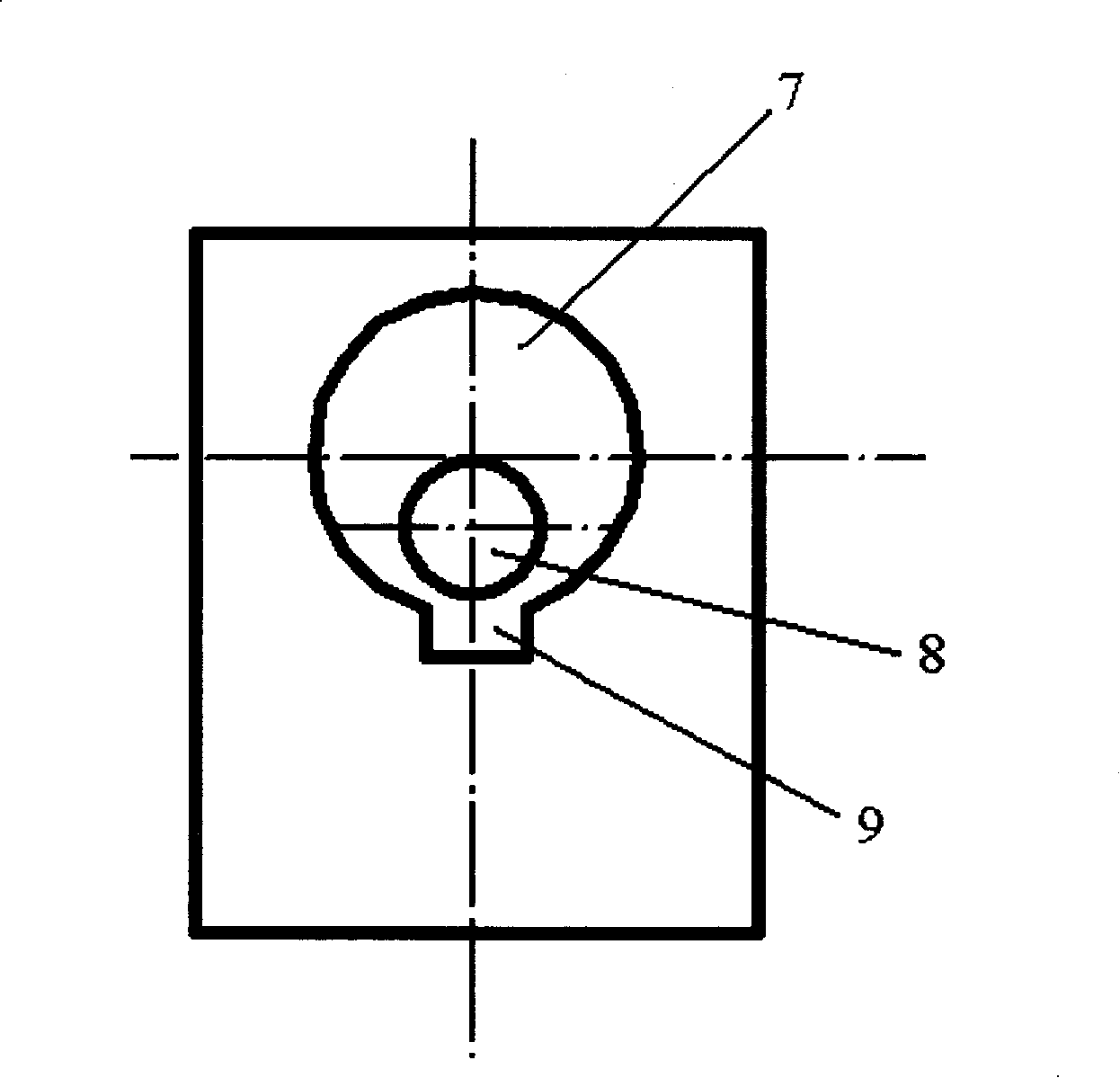

[0025] (3) Put a balance weight on the outside of each eccentric gear 2 of the multi-eccentric shaft, the balance part of the balance weight faces the other side of the eccentric gear eccentricity, and then align the upper axis of the multi-eccentric shaft with the described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com