Shaping Vibration Table of anode paste

A technology of anode paste and vibrating table, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of poor vibration isolation and noise reduction, large floor space and space, and large vibration hazards of buildings. Achieve the effects of good vibration isolation and noise reduction, small footprint and space, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

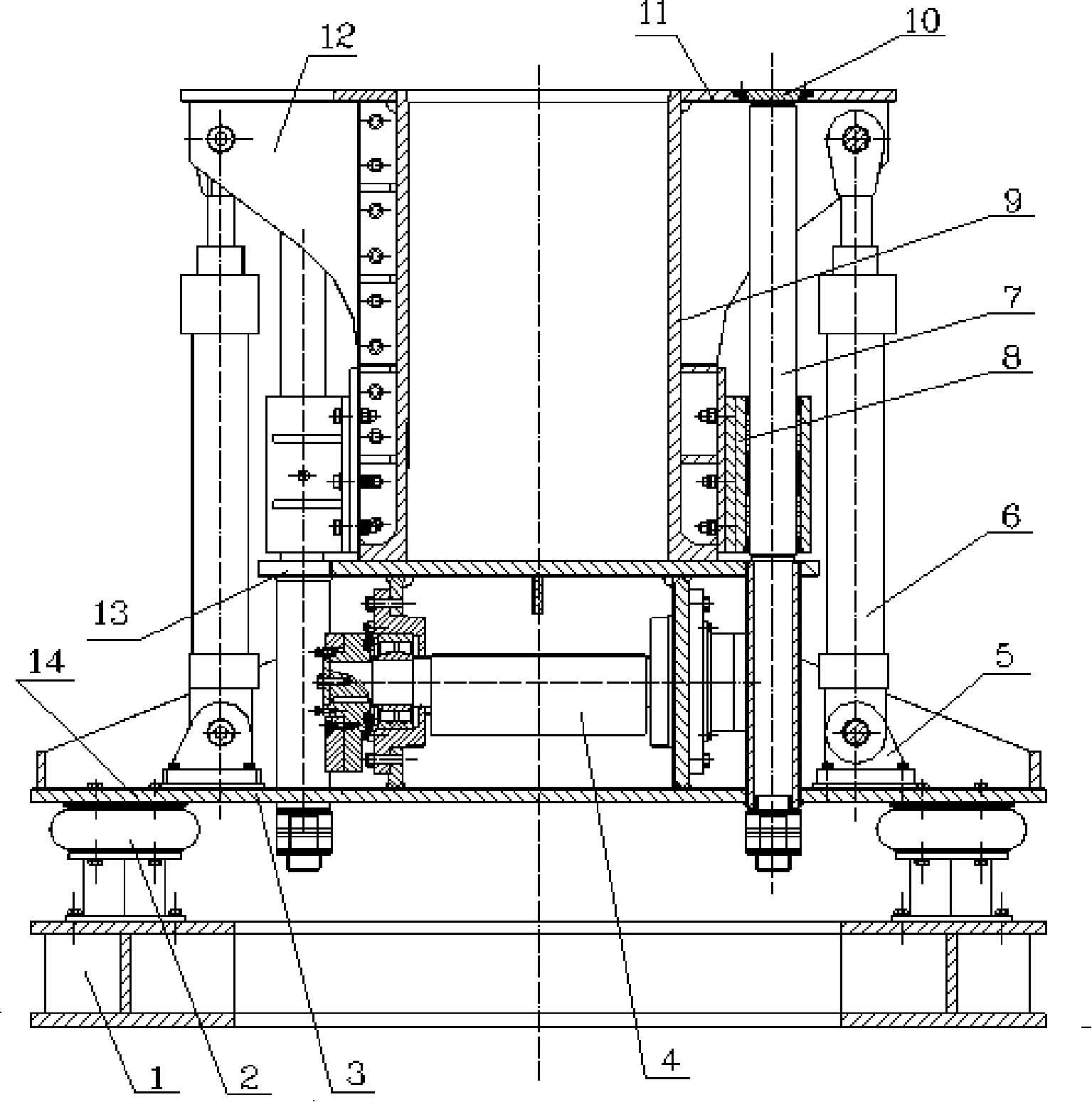

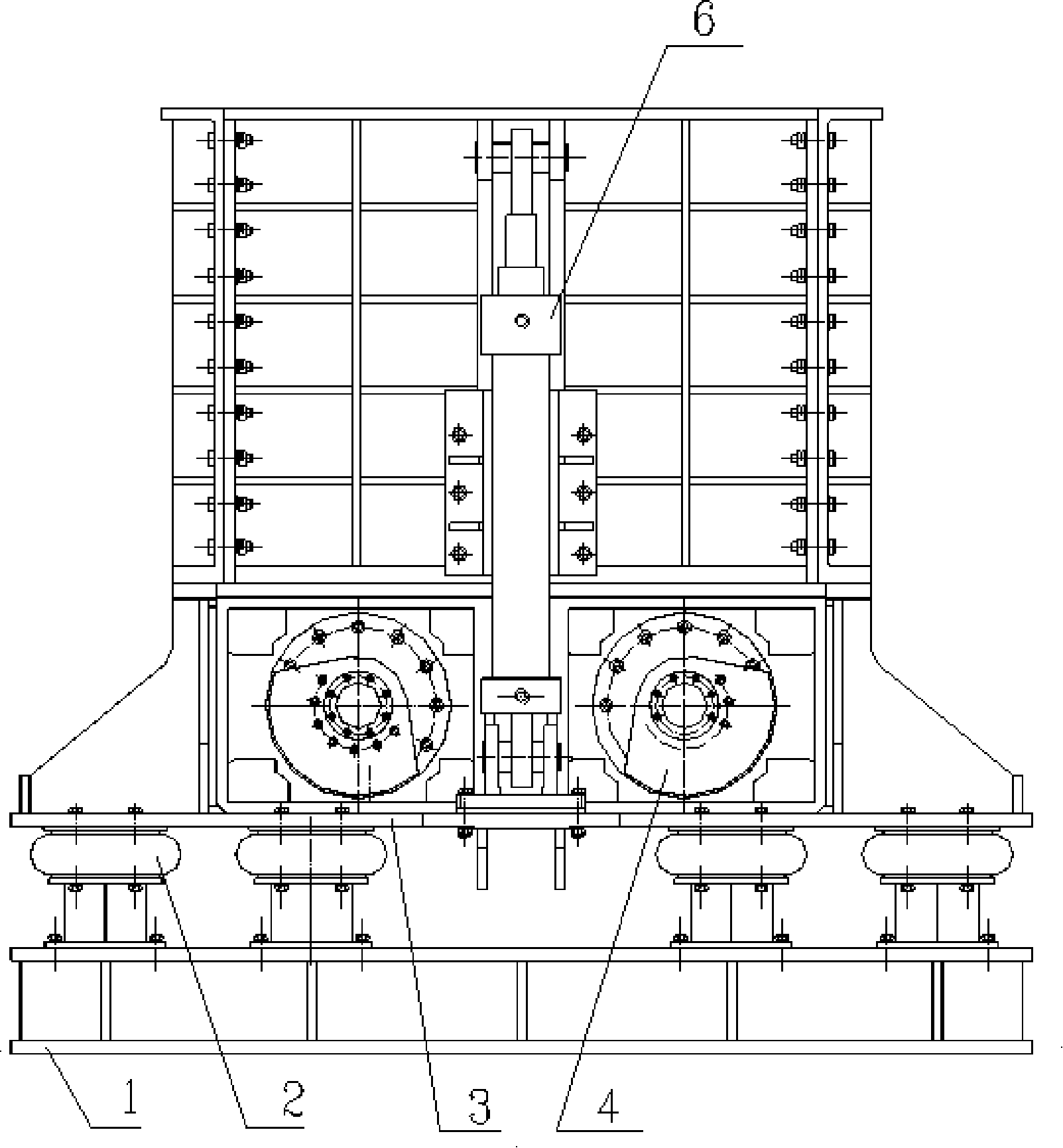

[0014] Embodiments of the present invention: as figure 1 , figure 2 As shown, the vibration isolator 2 adopts a rubber air bag, first install the vibration isolator 2 on the base 1, then fix the vibration box 3 on the vibration isolator 2, and then install two sets of vibration exciters 4 in the vibration box 3, The two sets of exciters 4 are symmetrically arranged and connected to the power unit; the guide sleeve 8 is installed on the left and right sides of the mold sleeve 9, and the mold sleeve 9 is placed on the top plate 13 of the vibration box 3, and the guide shaft 7 Pass through the mounting holes of the guide sleeve 8 and the top plate 13 and bottom plate 14 of the vibration box 3 and fix them with bolts, install the oil cylinder base 5 on the bottom plate 14 of the vibration box 3, then hinge one end of the oil cylinder 6 with the oil cylinder base 5, and the other One end is hinged with the ear plate 12 of the mold cover 9, and the left and right sides are carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com