Constant temperature and constant wetting type automatization impedance test system

A technology of impedance testing, constant temperature and humidity, applied in the transmission system, digital transmission system, measuring resistance/reactance/impedance, etc., can solve the problems of inefficiency, slow reading speed, interval control error of reading time, etc., to achieve The effect of shortening the test cycle, high cost-effectiveness, and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

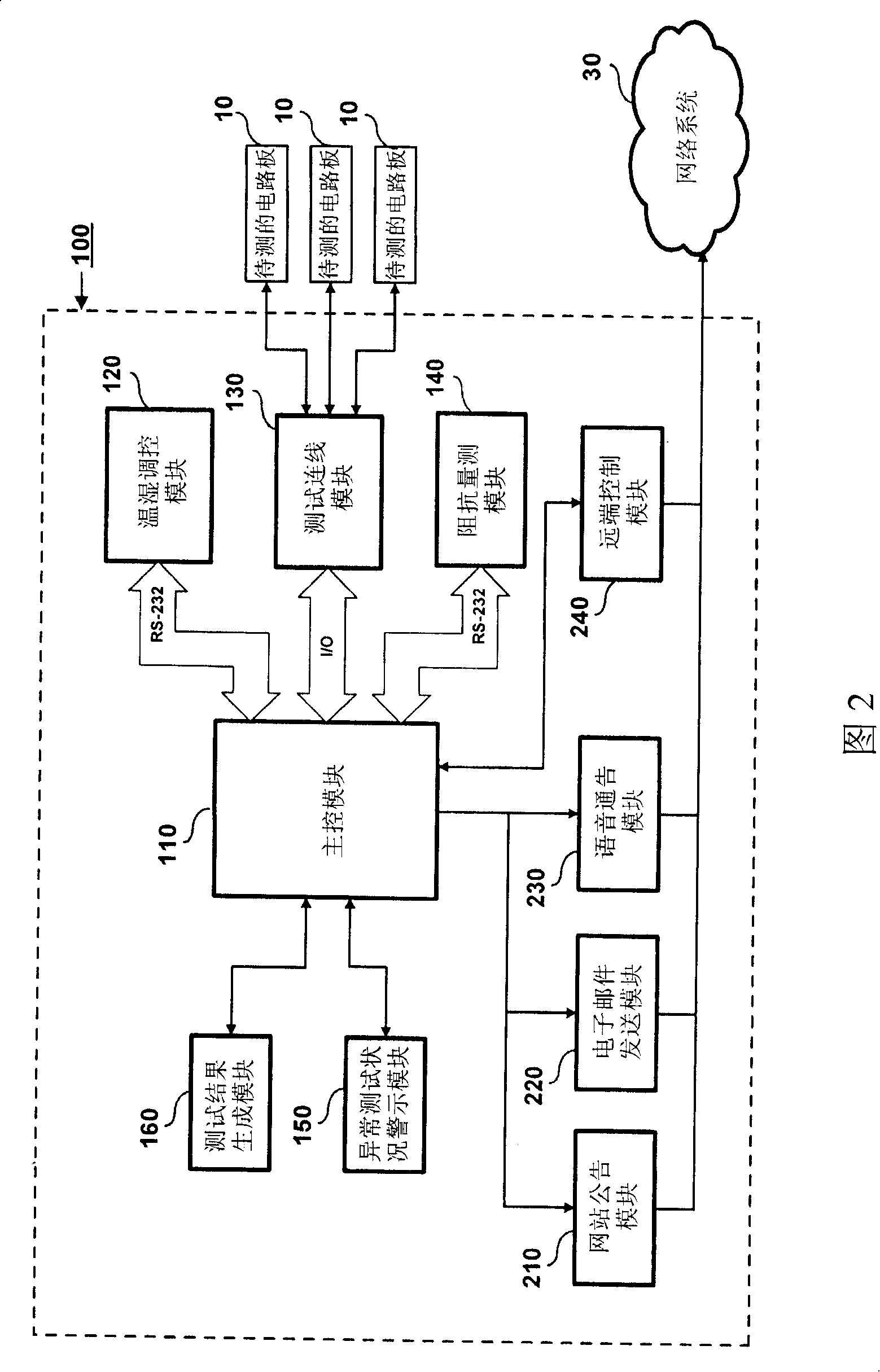

[0034] In the following, in conjunction with the attached drawings, embodiments of the constant temperature and humidity automatic impedance test system of the present invention are disclosed in detail.

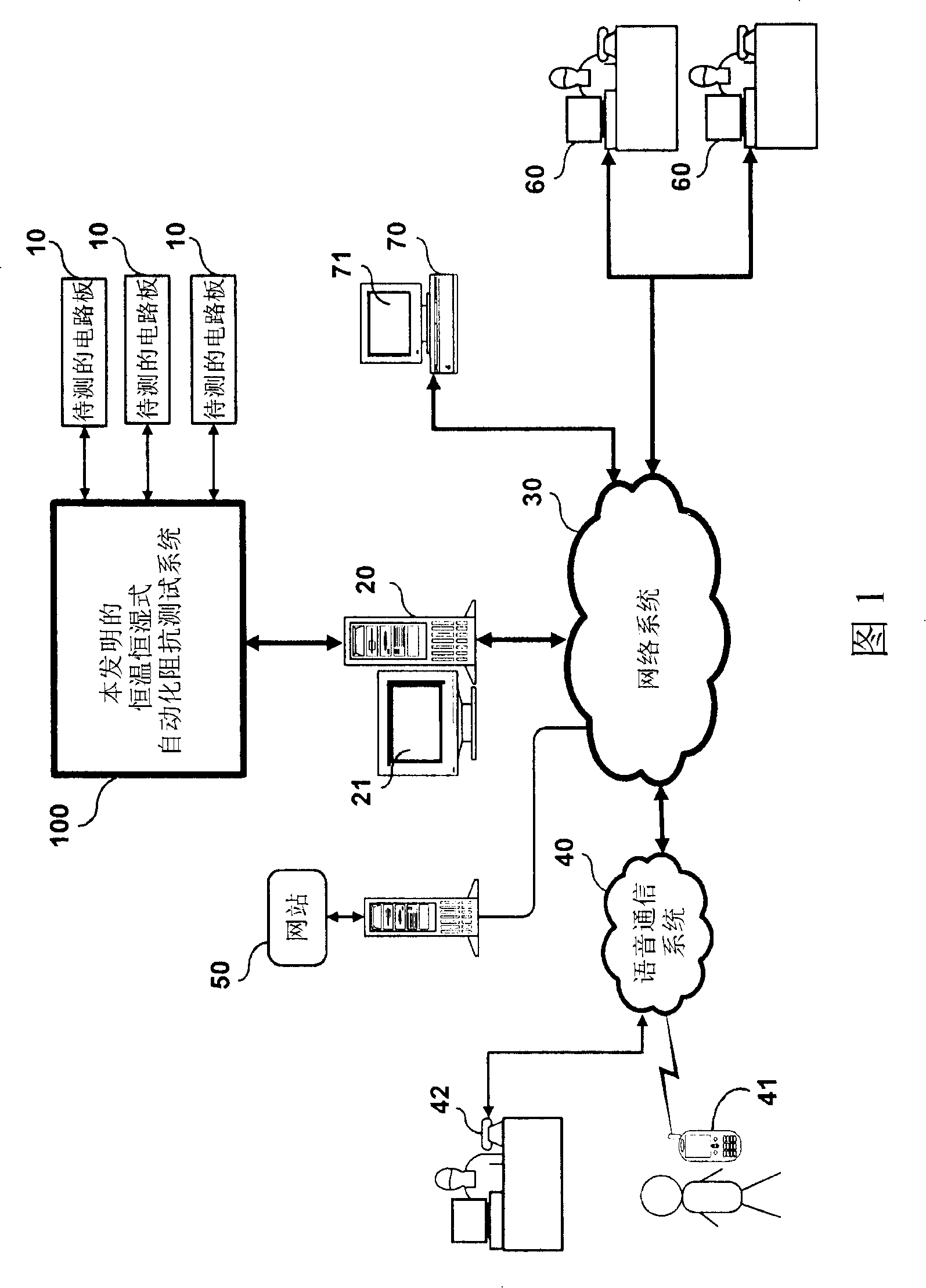

[0035] Fig. 1 shows the application mode of the constant temperature and humidity automatic impedance test system of the present invention (as indicated by the block 100). As shown in Figure 1, in practical applications, the constant temperature and humidity automatic impedance test system 100 of the present invention is matched to an industrial control terminal computer platform 20, and the industrial control terminal computer platform 20 is connected to a network system 30 and a Voice communication system 40. In specific implementation, the network system 30 may include, for example, the Internet, an intranet, an extranet, and a local area network (LAN), which can be used to connect to A website 50, a network workstation 60 for each relevant staff member, and a remote control w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com