Transformer with safety creepage distance

A creepage distance and transformer technology, which is applied in the field of transformers with safe creepage distance, can solve the problems of low product qualification rate and very high requirements for the production and processing of insulating bushings, so as to increase the product qualification rate and facilitate mass production Effect of processing and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

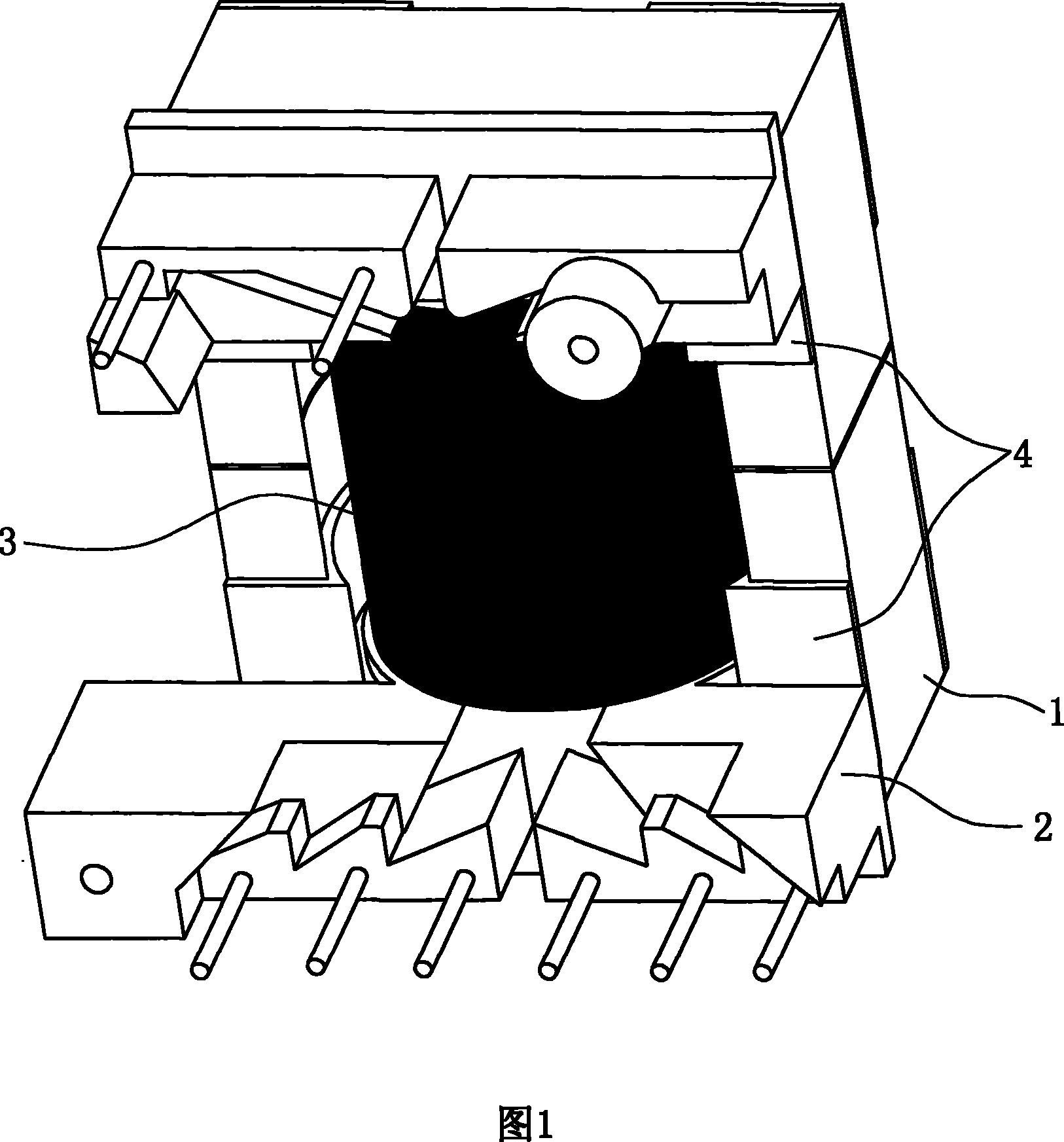

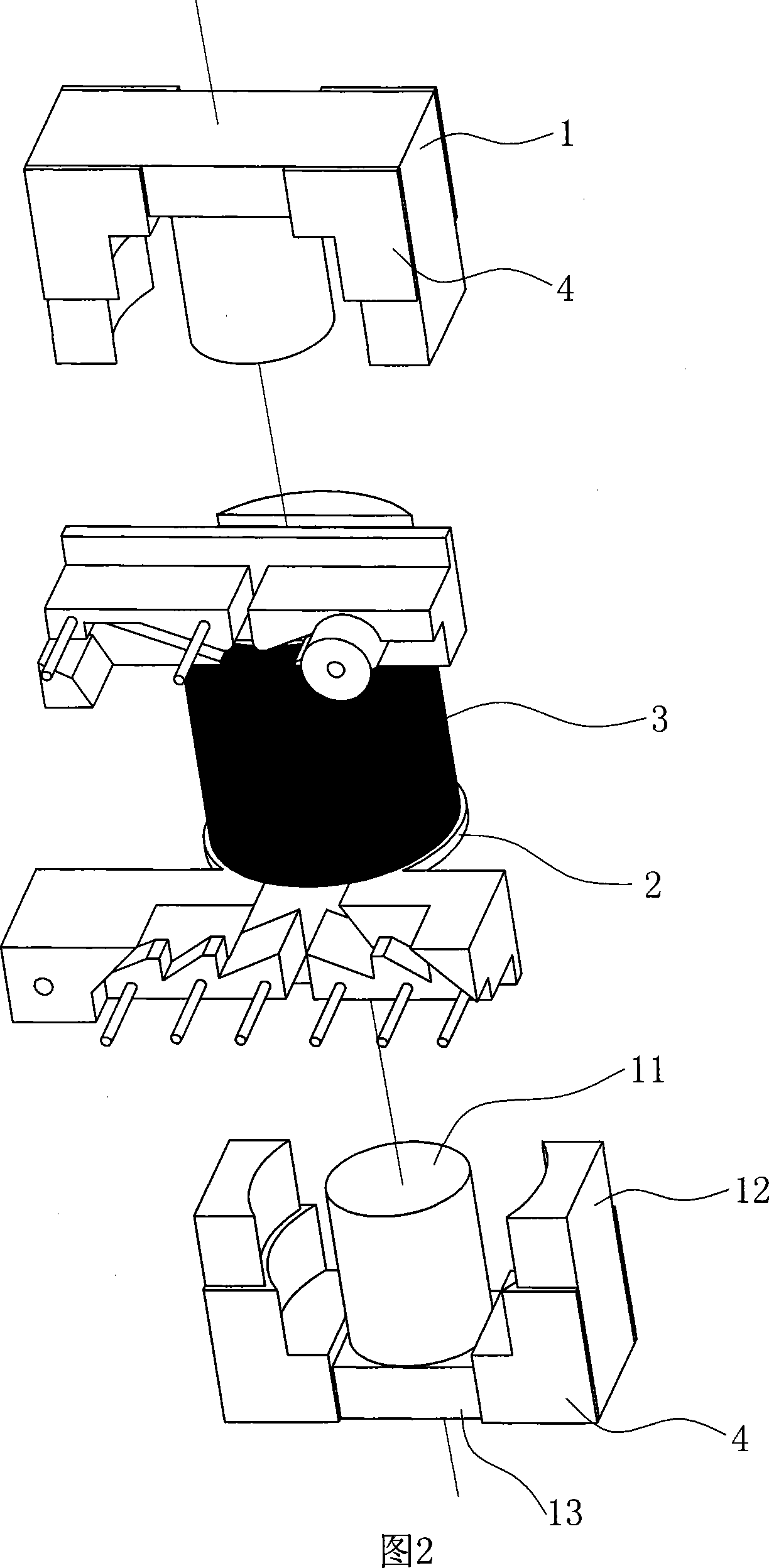

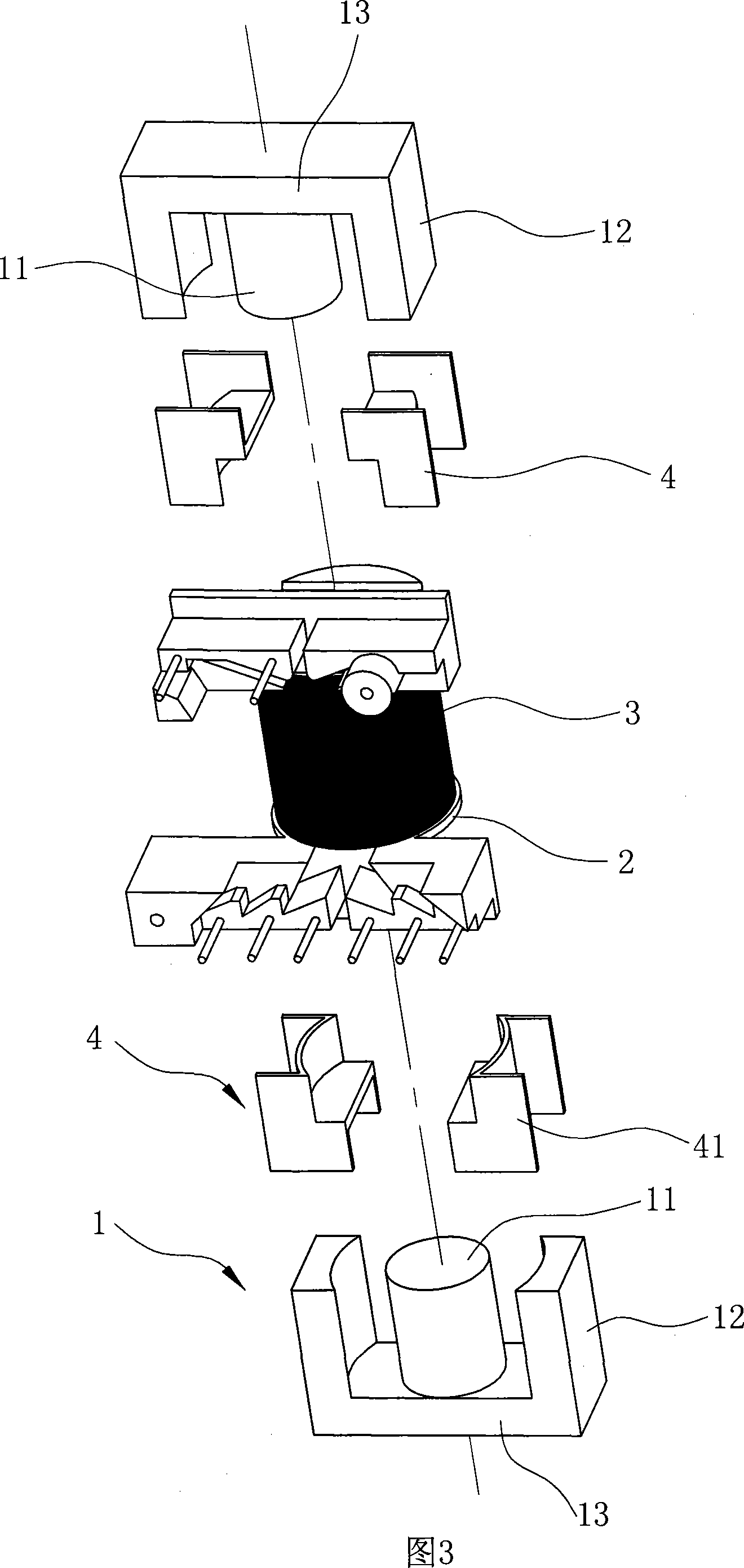

[0022] Such as Figure 1 ~ Figure 3 As shown, it is Embodiment 1 of the present invention. The transformer with a safe creepage distance includes two E-shaped iron cores 1 and a cylindrical insulating material sleeved on the center column 11 of the E-shaped iron core 1. coil support 2;

[0023] Wherein, a coil 3 is wound on the coil support 2;

[0024] The side columns 12 and the central column 11 of the two E-shaped iron cores 1 are opposite to each other, and the cylindrical coil support 2 is sleeved on the central columns 11 of the two E-shaped iron cores 1 through its central hole;

[0025] On both sides of the center column 11 of the E-shaped iron core 1, an insulating spacer 4 is respectively arranged oppositely. respectively attached to the sides of the side columns 12 and the bottom edge 13 of the corresponding E-shaped iron core 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com