Crossover position automatic adjustment technologies for servovalve of hydraulic pressure AGC control system

A control system and automatic adjustment technology, applied in rolling mill control device, servo motor assembly, fluid pressure actuating device, etc., can solve problems such as control sensitivity and stability decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment.

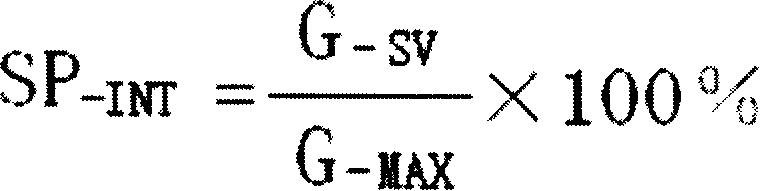

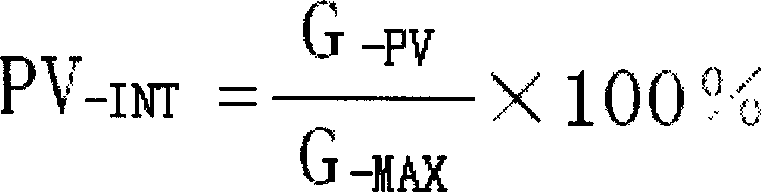

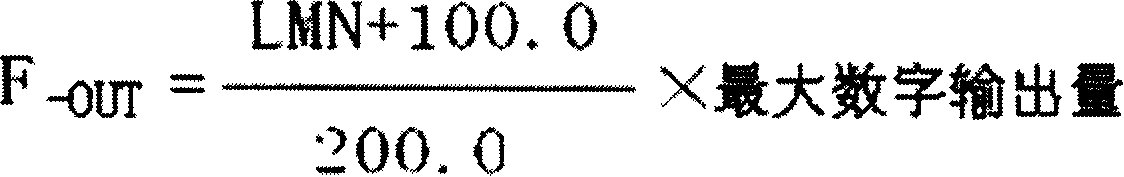

[0034] The hydraulic AGC control system of this embodiment uses Siemens STEP 7 programming software. The method for automatically adjusting the zero position of the servo valve is to call FB41 to continuously control the PID intelligent regulator module in the Siemens STEP 7 programming software, and fill in the corresponding parameters after processing. to the corresponding position, and then convert the control output value LMN of the PID intelligent regulator module into the given value of the analog output module to control the opening of the servo valve. The parameters related to control in the calculation follow the following rules:

[0035] SP - INT = G - SV G - M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com