Printing press with printing plate manipulation device

A printing machine and printing device technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of paper moisture and easy deformation of texture, and achieve the effect of overcoming geometric structure deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

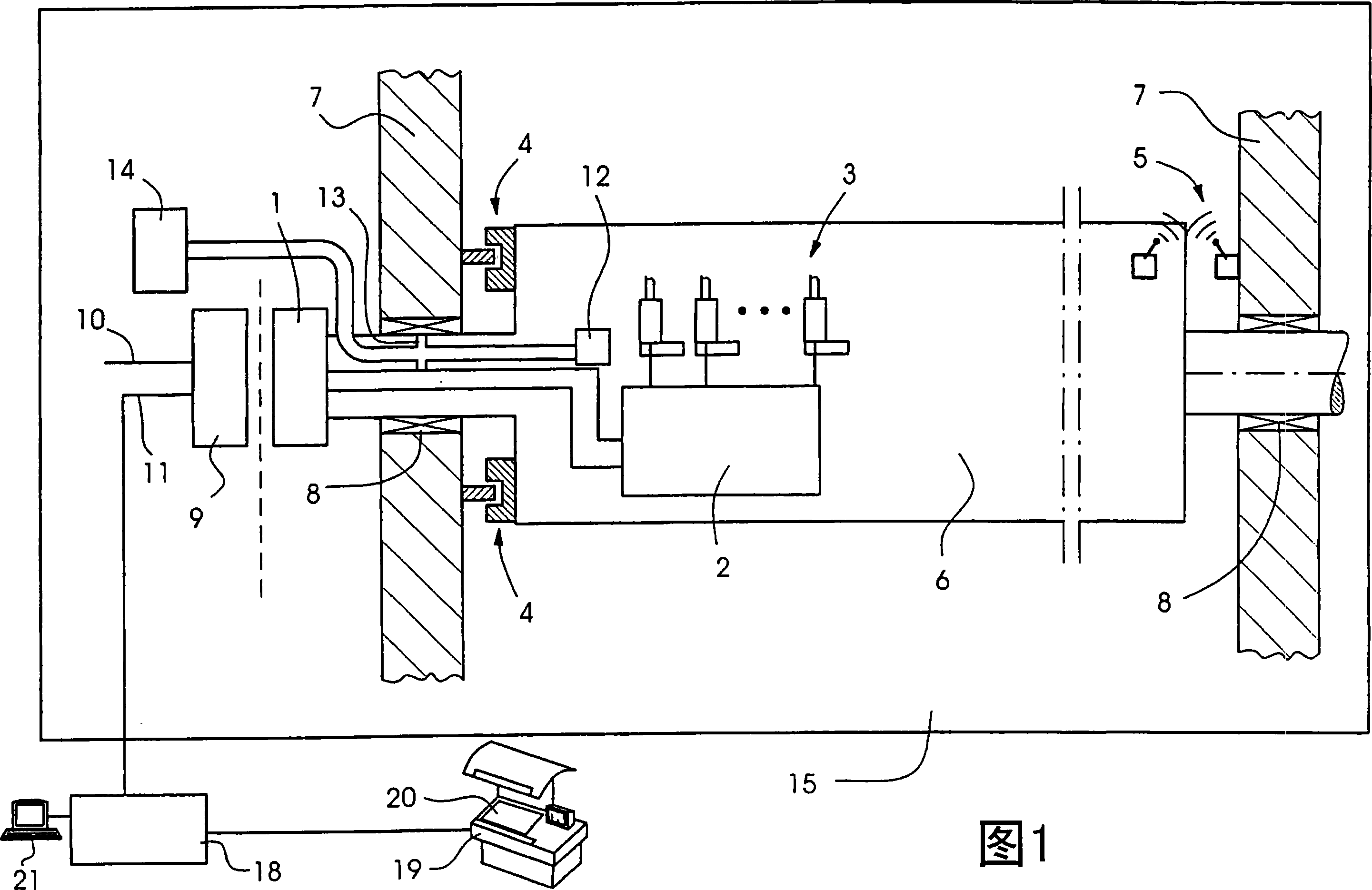

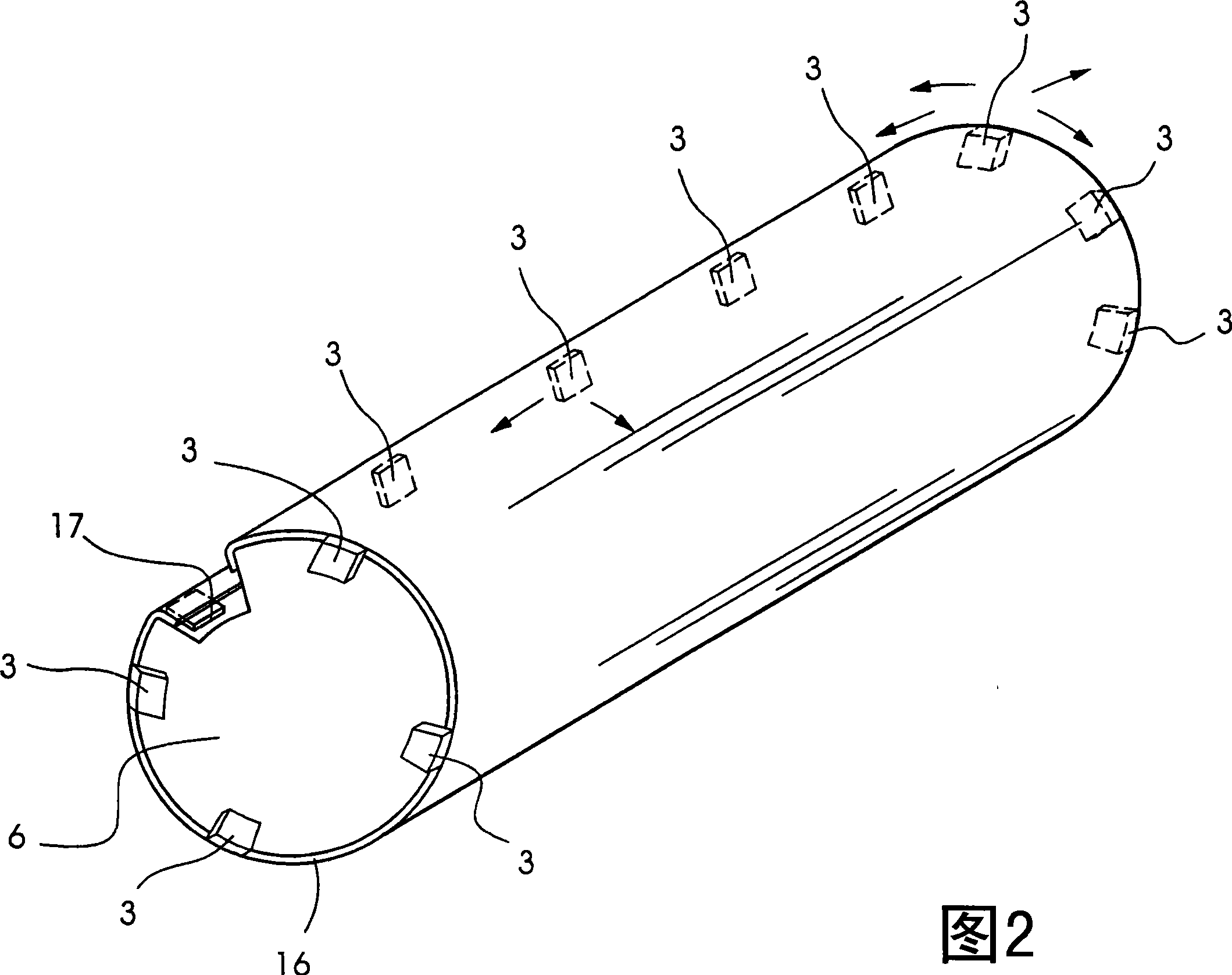

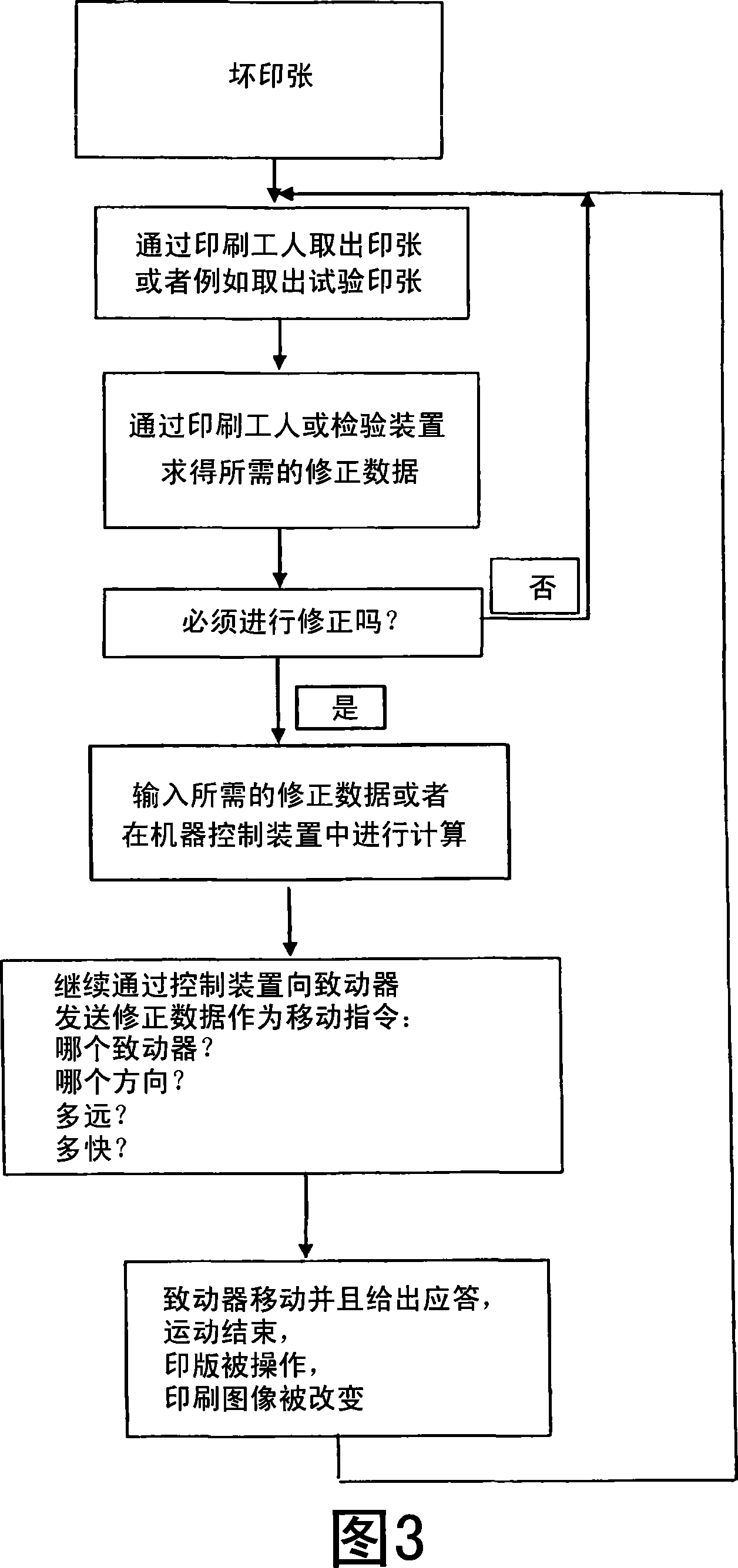

[0025] A part of a printing unit of a sheet-fed printing press 15 is schematically shown in FIG. 1 . This part includes the plate cylinder 6 , the lateral supports 8 and a part of the control of the actuator 3 . The plate cylinder 6 is mounted rotatably on both sides in corresponding side walls 7 of the printing press 15 . A plurality of actuators 3 are arranged on the plate cylinder 6, said actuators 3 each engaging (angereifen) on the outer edge of a printing plate located on the plate cylinder 6, which is shown in detail in FIG. 2 . Through the movement of these actuators 3 , the printing plates 16 located on the plate cylinder 6 can be deformed not only in the circumferential direction but also in the axial direction. The deformation of the printing plate 16 simultaneously changes the printing image on the printing plate 16 accordingly. The actuators 3 are operated as electric motors in FIG. 1 , which are connected to a positioning electronics unit 2 . The positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com