Piston with oil collector ring

An oil collecting ring and piston technology, applied in the direction of piston, piston ring, cylindrical piston, etc., can solve the problems of affecting the distribution of lubricating oil, inappropriate, etc., and achieve the effect of full sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

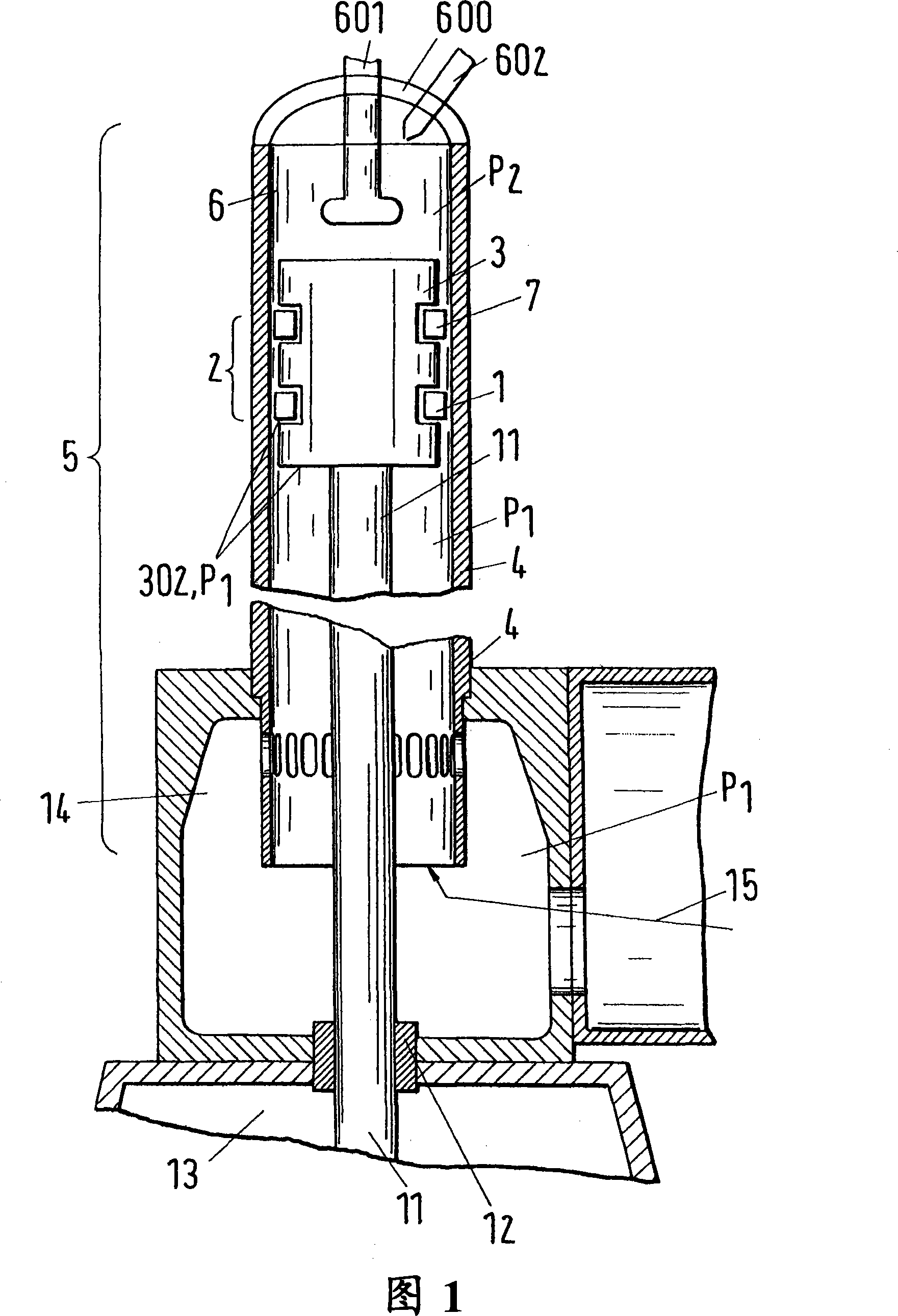

[0093] Figure 1 shows a schematic illustration of a cylinder arrangement in partial section with a cylinder liner, a piston according to the invention and a fresh air supply system, wherein the piston comprises a piston ring set with an oil collector ring, the oil collector ring In the following text, it is indicated generally with the reference number 1 .

[0094] The cylinder arrangement of Fig. 1 is a typical arrangement for longitudinally scavenged large two-stroke Diesel machines known per se from the prior art.

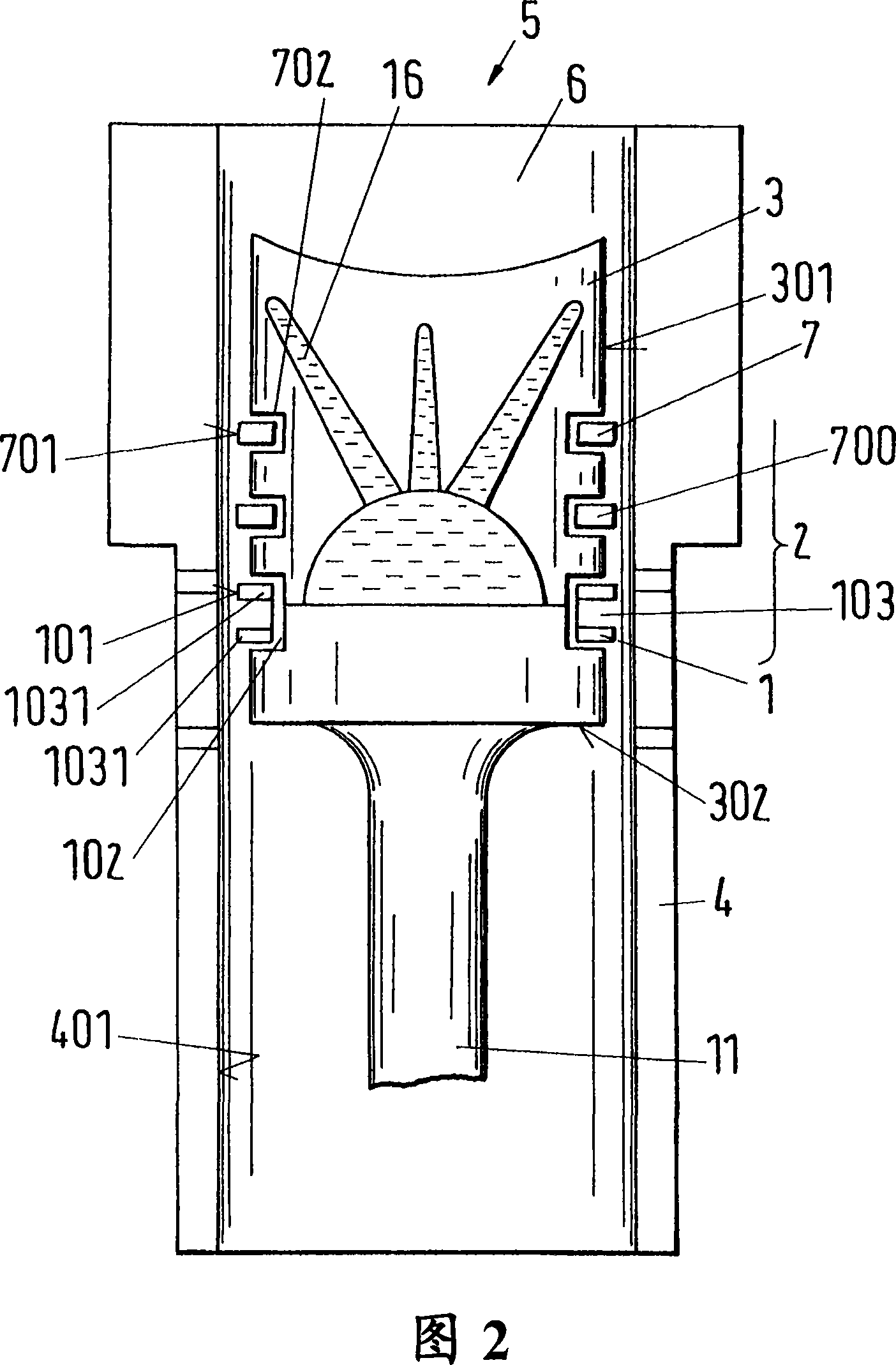

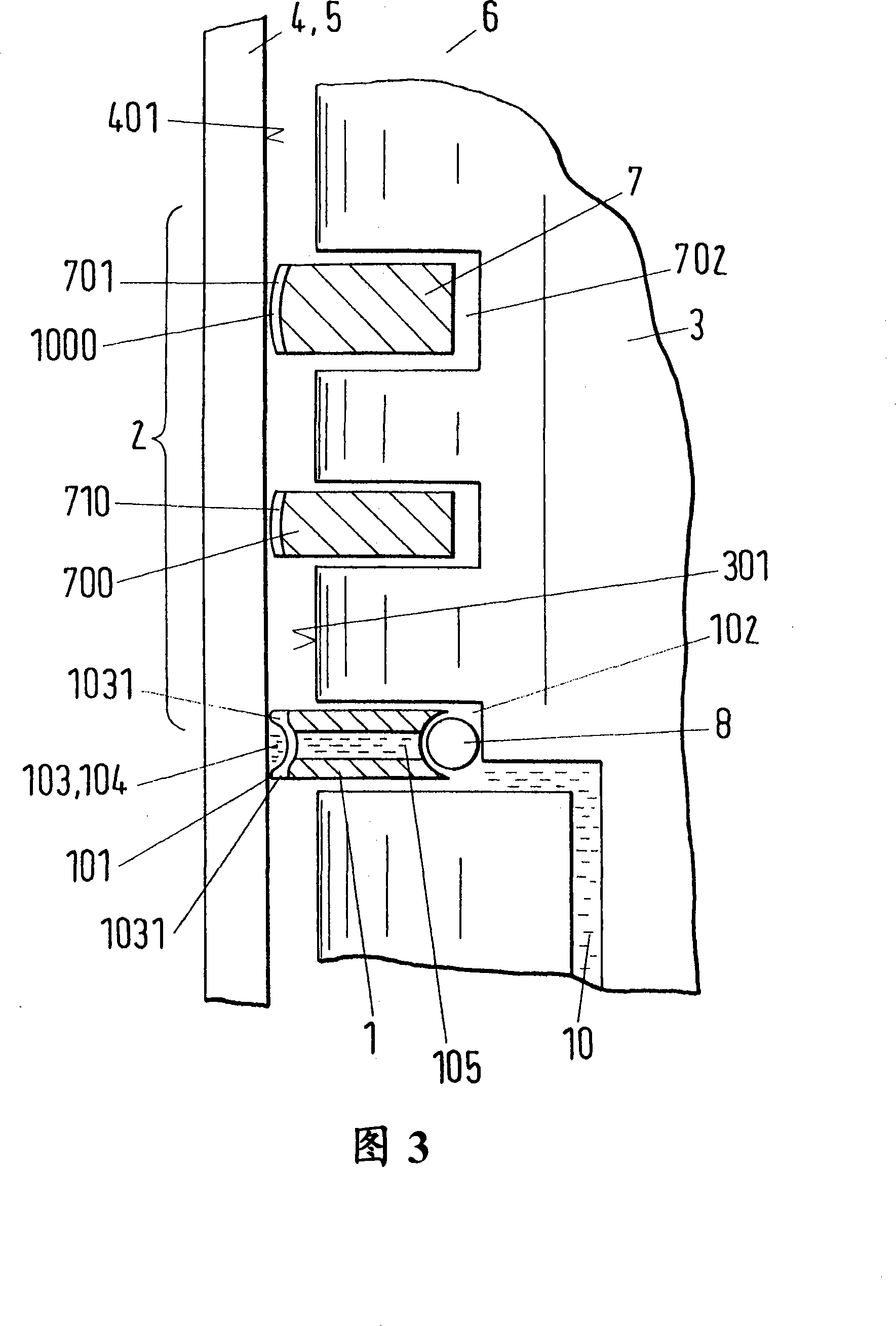

[0095] The arrangement comprises a cylinder 5 , also indicated as a cylinder liner 5 , wherein a piston 3 is arranged to be able to move back and forth along a cylinder wall 4 of the cylinder 5 . The piston 3 comprises a piston ring set 2 which is here schematically illustrated with only two piston rings, ie with a first piston ring 7 located closest to the combustion chamber 6, which is also called top ring 7 and has a first running surface 701 with which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com