Permanent magnetic suspension and magnetic wheel pushing vehicle

A magnetic levitation and magnetic wheel technology, which is applied to electric vehicles, vehicle parts, railway car body parts, etc., can solve the problems of inability to apply existing rail transit transformation, high operation and maintenance costs, complex structure and technology, and save permanent magnets And supporting materials, low requirements for construction accuracy, strong suspension and guiding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

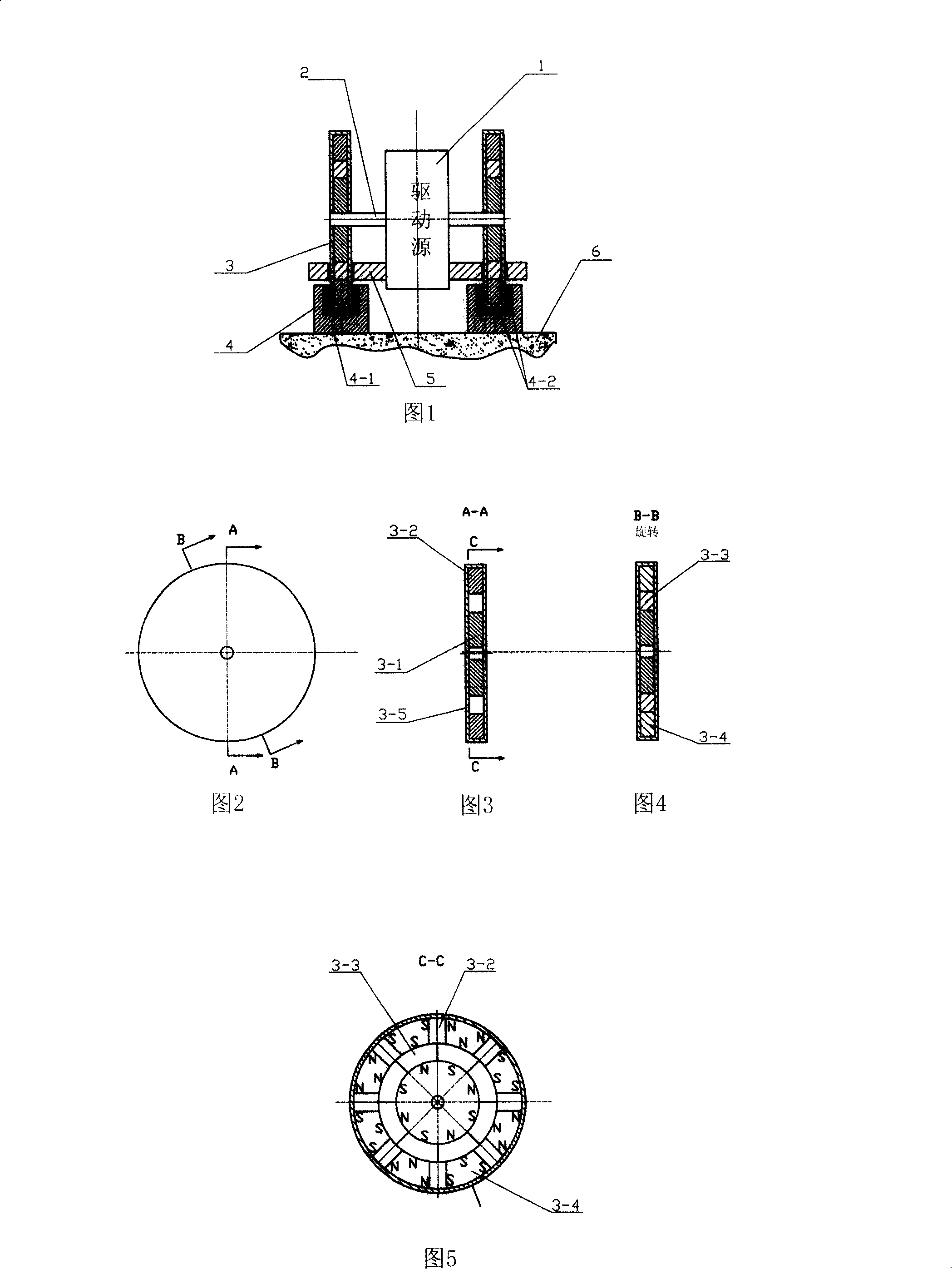

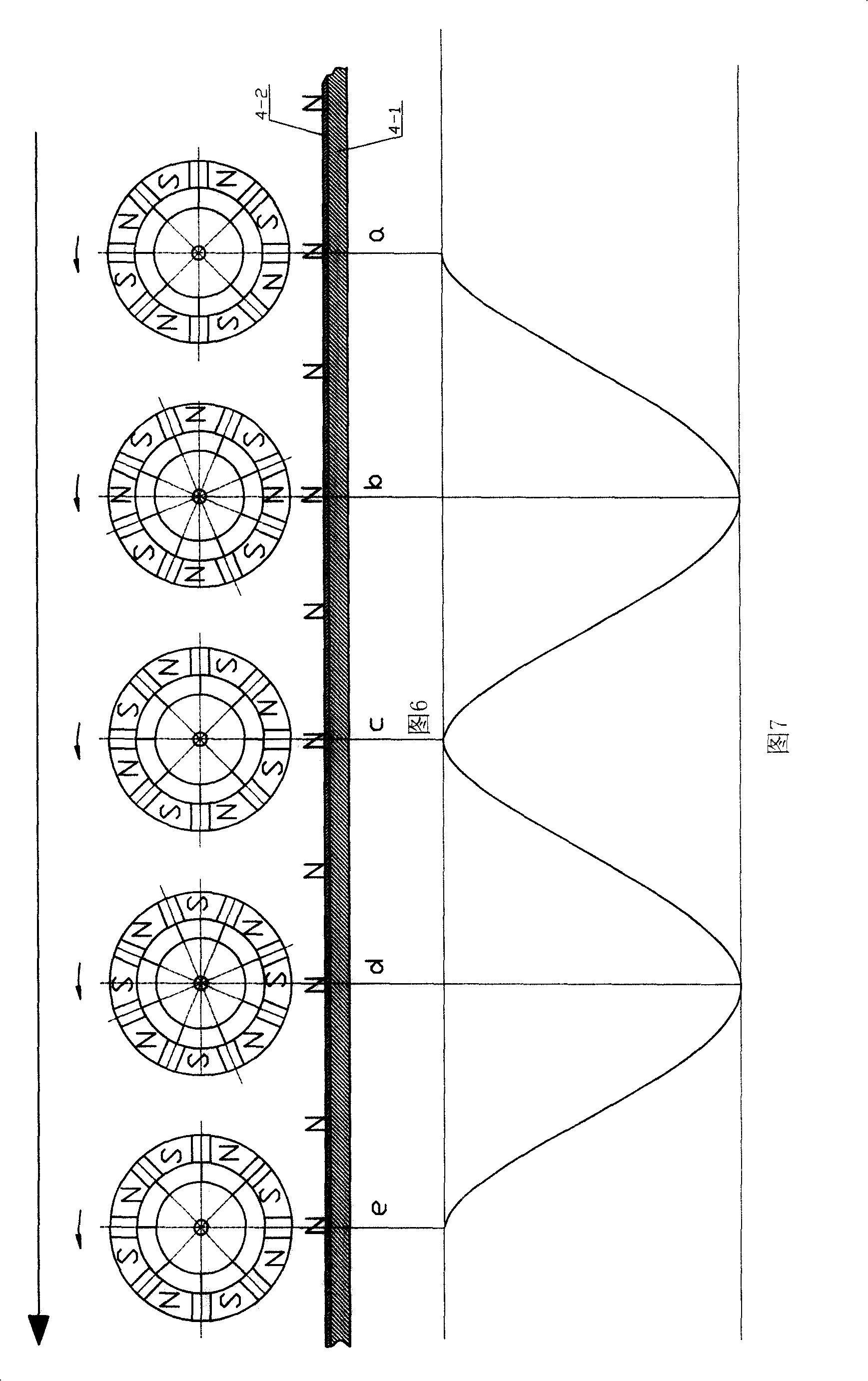

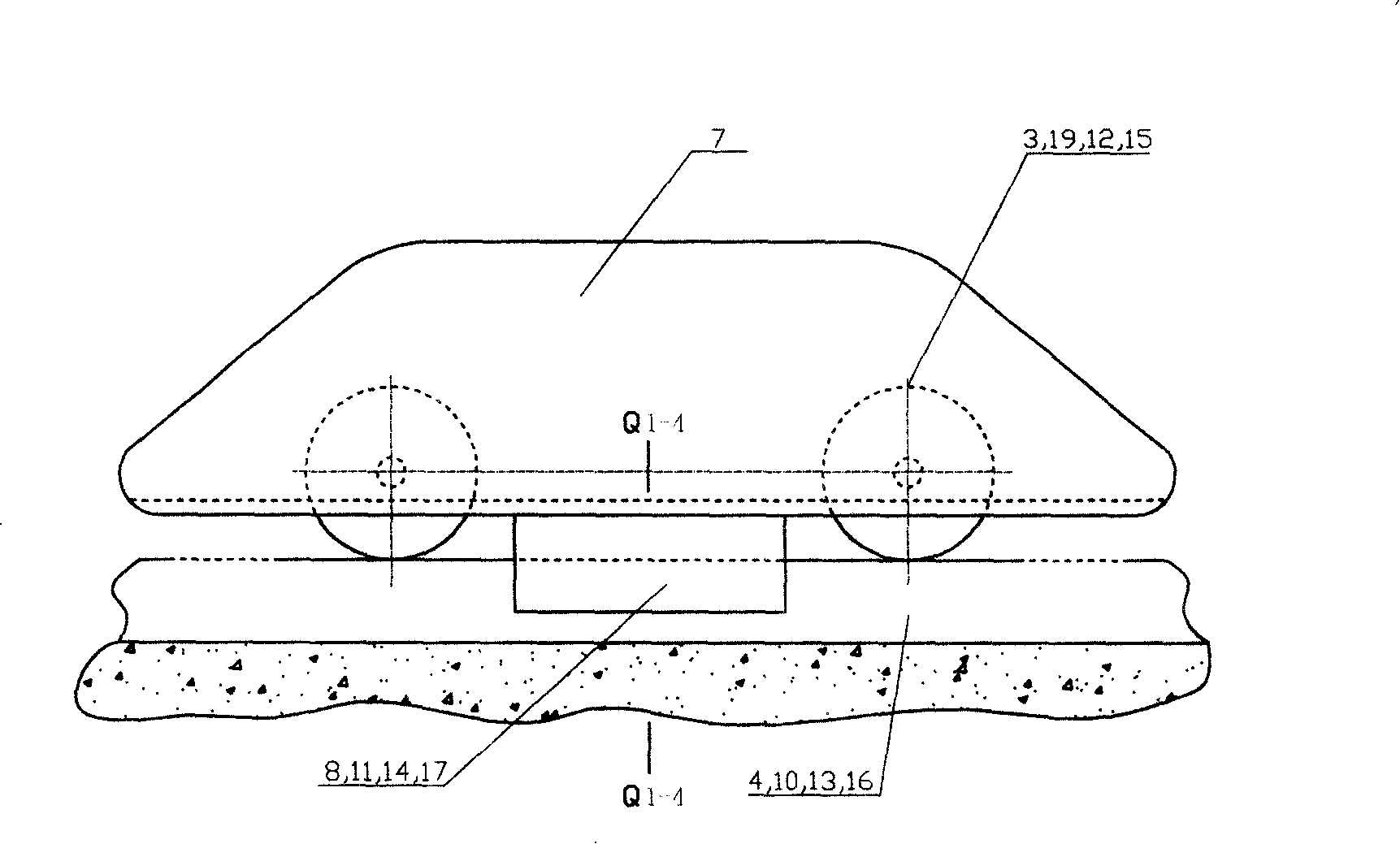

[0068] Specific implementation mode one: as shown in Figure 1 to Figure 9 shown.

[0069] The magnetic wheel 3 is composed of a magnetic conduction disk 3-1, a tile-shaped permanent magnet block 3-3 magnetized in the radial direction, a permanent magnet block 3-2 magnetized in a tangential direction, a fan-shaped magnetic conduction block 3-4 and a non-conductive magnetic block 3-4. The magnetic material cladding plate 3-5 is assembled and consolidated as shown in Figure 2 to Figure 4, and the permanent magnetic block 3-3 of the tile can also be partitioned along the circumferential direction with the integral permanent magnetic ring, and the multi-pole polarity is alternated along the radial direction Manufactured by magnetization, the circumferential interface of the tile-shaped permanent magnet block 3-3 and the neutral plane of the permanent magnet block 3-2 are on the same radial line of the magnetic wheel 3, and perpendicular to the end face of the magnetic wheel 3, Ad...

specific Embodiment approach 2

[0072] Specific embodiment two: as shown in Fig. 10 to Fig. 20 .

[0073] The cross-section of the magnetically permeable base 10-1 of the track 10 is made into a rectangle, and the permanent magnet plate 10-2 that is magnetized along the thickness direction is consolidated on the top, the left side, and the right side; The right three magnetic wheels are combined and connected, and then encapsulated and consolidated with non-magnetic material plates 9-7. The left and right magnetic wheels are parallel and symmetrical, and the structure and material of the middle magnetic wheel are completely the same as the magnetic wheel in the specific embodiment one; 2. The permanent magnet block 9-5 magnetized along the tangential direction, the sector-shaped magnetic block 9-8, and the sector-shaped permanent magnet block 9-9 magnetized along the axial direction (thickness) are combined and consolidated, wherein the adjacent The permanent magnet blocks 9-5 are relatively opposite with t...

specific Embodiment approach 3

[0075] Specific embodiment three: as shown in Fig. 21 to Fig. 28 .

[0076] The magnetically conductive track seat 13-1 of the track 13 is made with a V-shaped groove in the middle of the top, and a permanent magnet plate 13-2 magnetized along the thickness direction is consolidated in the V-shaped groove; as shown in Figures 22 to 27, the magnetic wheel 12 Consists of non-magnetic cylinder 12-1, discus-shaped magnetizer 12-3, sector-shaped magnetizer block 12-2, permanent magnet block 12-4 magnetized along the tangential direction and sector-shaped permanent magnet block 12 magnetized along the thickness direction -5 and non-magnetic material cladding plate 12-6 are combined and consolidated; the manufacturing method of the sector-shaped permanent magnet block 12-5 is similar to that of the sector-shaped permanent magnet block 9-9 of the magnetic wheel 9 described in the second embodiment , the only difference is that the sector-shaped permanent magnet block 9-9 is flat, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com