Railway wagon steering frame oscillating device

A technology for swinging devices and railway wagons, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, which can solve the problems of difficult performance guarantee and small lateral displacement of the bogie structure, so as to reduce maintenance costs and improve vehicles Dynamic performance, effect of reducing derailment coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

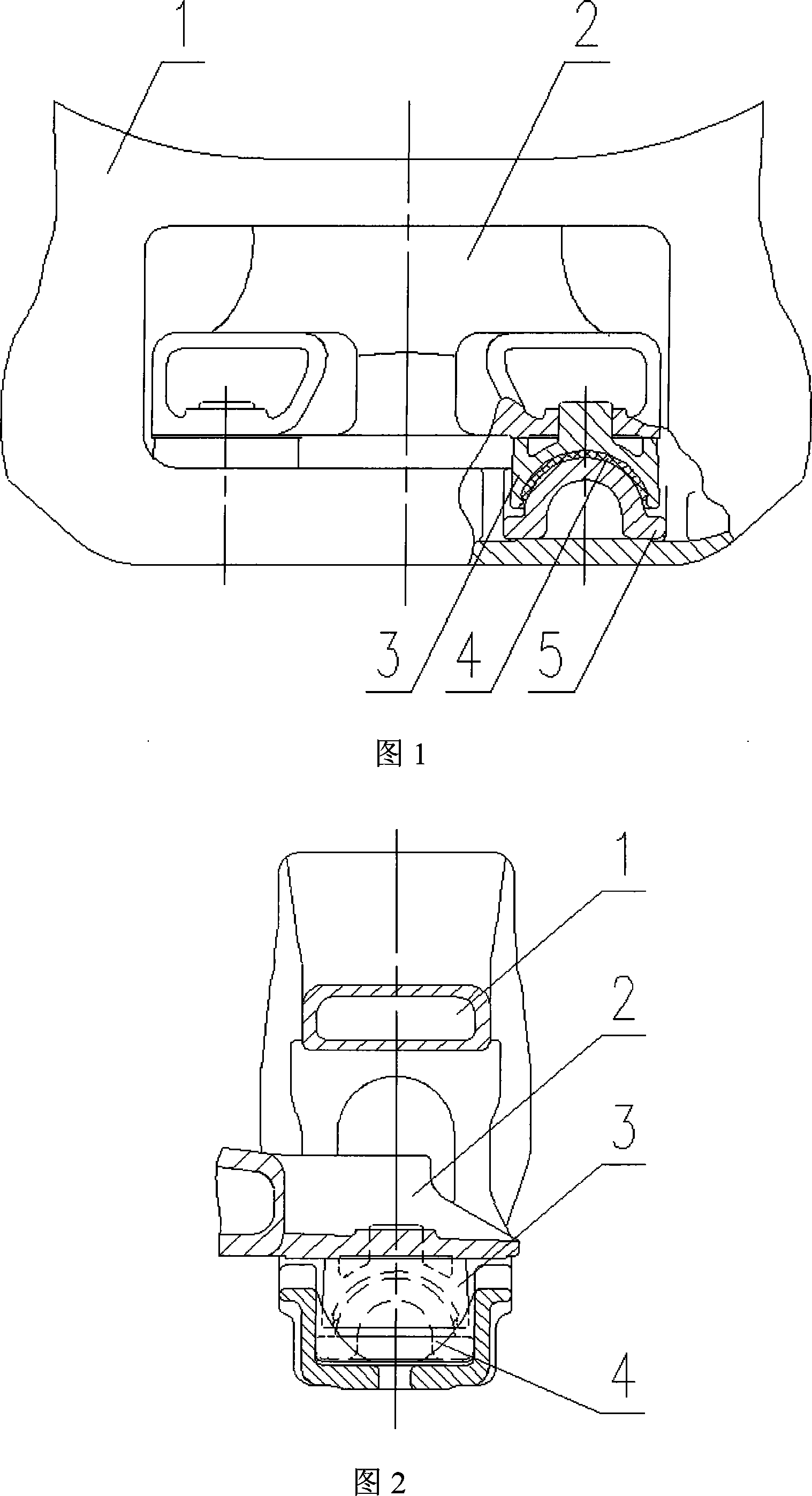

[0013] Referring to Fig. 1 and Fig. 2, a railway freight car bogie swing device is characterized in that the swing device is designed to connect the bogie bolster 1 with the side frame 2 and adopts a ball joint structure, and the swing device consists of a swing seat 3. The arc-shaped wear-resistant bushing 4 and the positioning hemisphere 5 are composed; there is a concave spherical surface on the swing seat 3, and the arc-shaped wear-resistant bush 4 is press-fitted on the concave spherical surface of the swing seat 1. In the arc-shaped wear-resistant bushing 4, the concave spherical surface of the arc-shaped wear-resistant bush 4 cooperates with the positioning hemisphere 5; the swing seat 1 is connected to the bolster 1 through the interference fit between the column and the hole, and the positioning hemisphere 5 is set On side frame 2.

[0014] The swing seat in the swing device is connected to the bolster through the interference fit between the column and the hole, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com