Method for using low friction pair moving weight

A low-friction, heavy-object technology, applied in the field of heavy-object movement, can solve problems such as damage to heavy objects or moving devices, crushing of balls or rollers, damage to heavy-object moving devices, etc., achieving light weight, easy operation, and high pressure resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

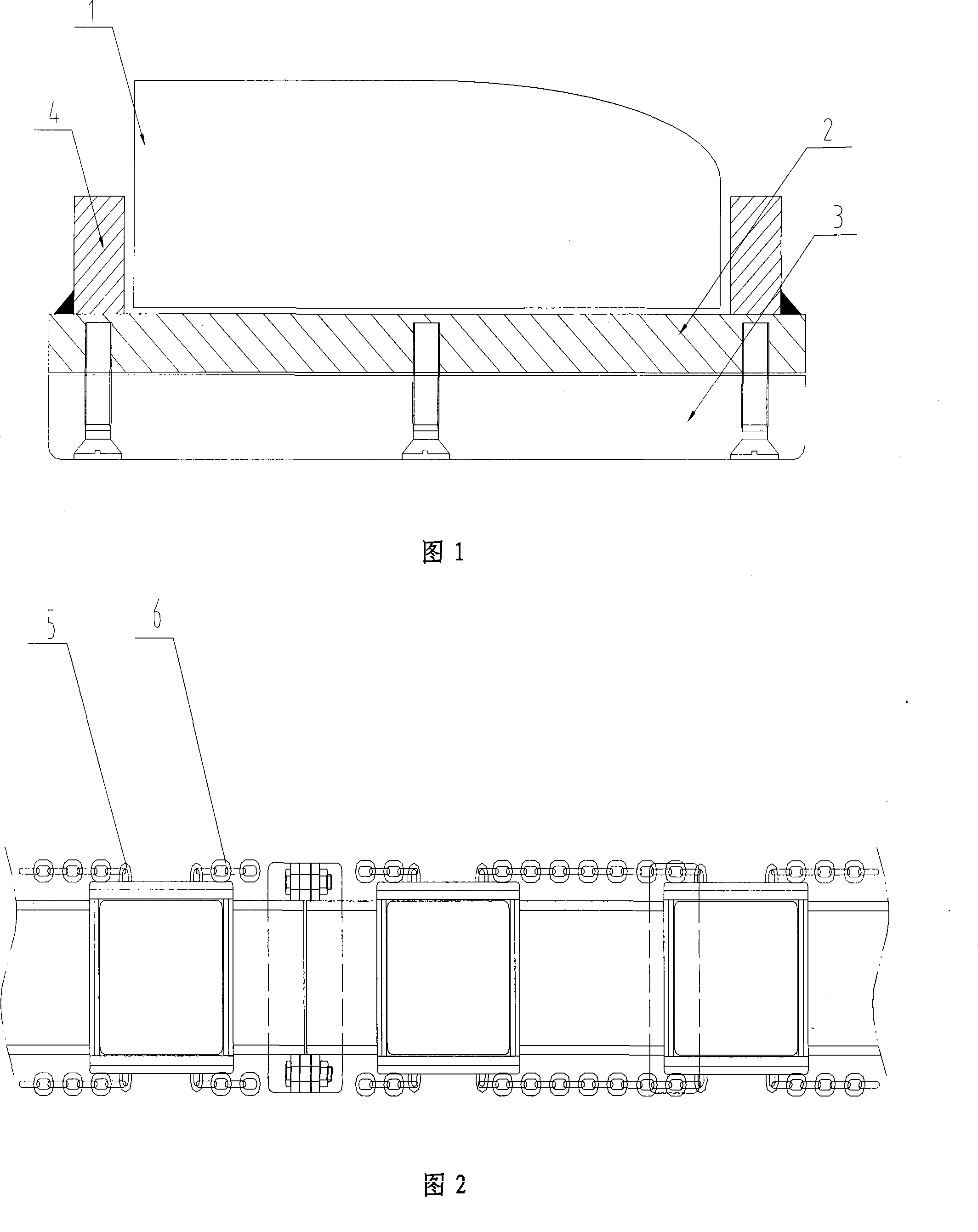

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] The present invention is carried out according to the following steps: first, a low-friction high-pressure resistant slider is placed on a low-friction carrier. The steel plate 2 and the low-friction pressure-resistant layer 3 are composed, and the baffles 4 are respectively fixed around the top surface of the low-friction and high-pressure resistant slider; secondly, heavy structures are placed on the low-friction and high-pressure resistant slider (generally, multiple low-friction and high-pressure resistant sliders are required) Blocks), and finally pull the heavy structure to move (it can move in any direction). Lubricants can be arranged between the low-friction high-pressure resistant material and the stainless steel plate, such as smearing butter, which can further reduce the friction coefficient between the low-friction high-pressure resistant material a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com