Method of fabricating nano structure, method of manufacturing magnetic disc, method of forming stamper, and method of generating base body

A technology of nanostructure and manufacturing method, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., capable of solving problems such as unrealistic and unsuitable mass production of magnetic disks 11

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0090] FIG. 4 is a flowchart showing a magnetic disk manufacturing method as one embodiment of the present invention.

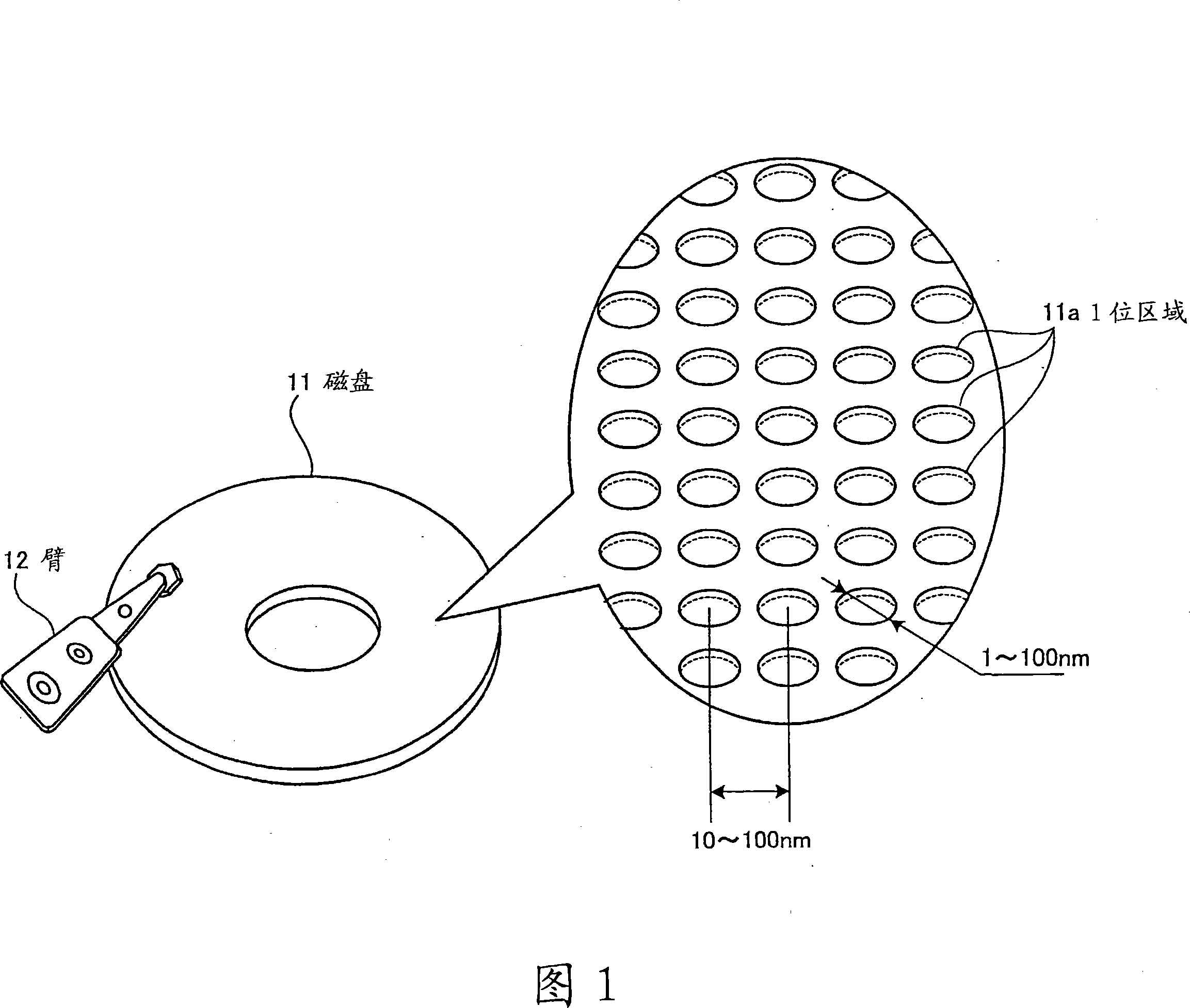

[0091] The magnetic disk manufacturing method shown in FIG. 4 corresponds to one embodiment of the magnetic disk manufacturing method according to the present invention, and the method is formed by forming a multi- A method for manufacturing a magnetic disk with a 1-bit region 11a, the method includes a stamper preparation step (step S100) and a manufacturing step (step S200).

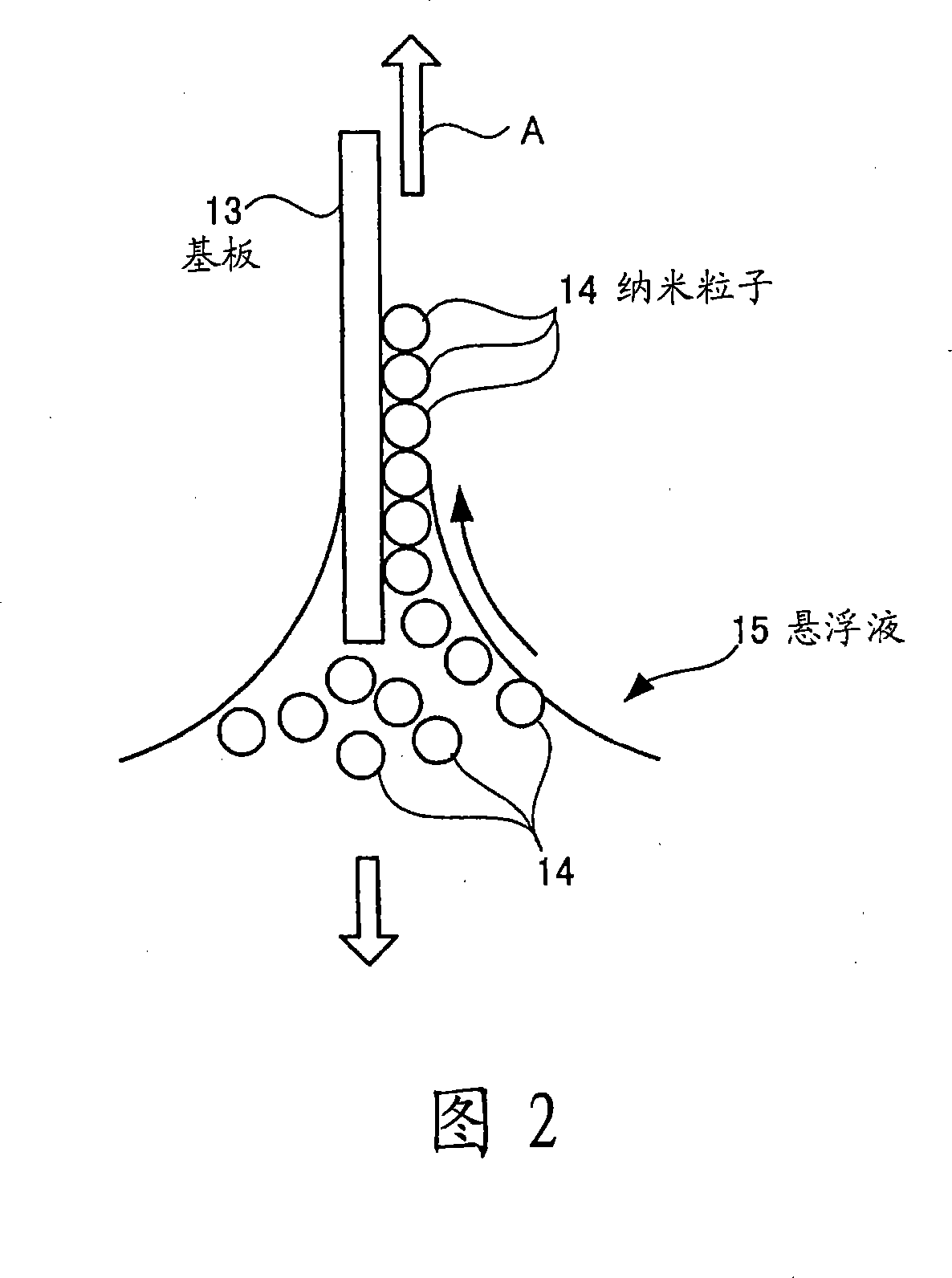

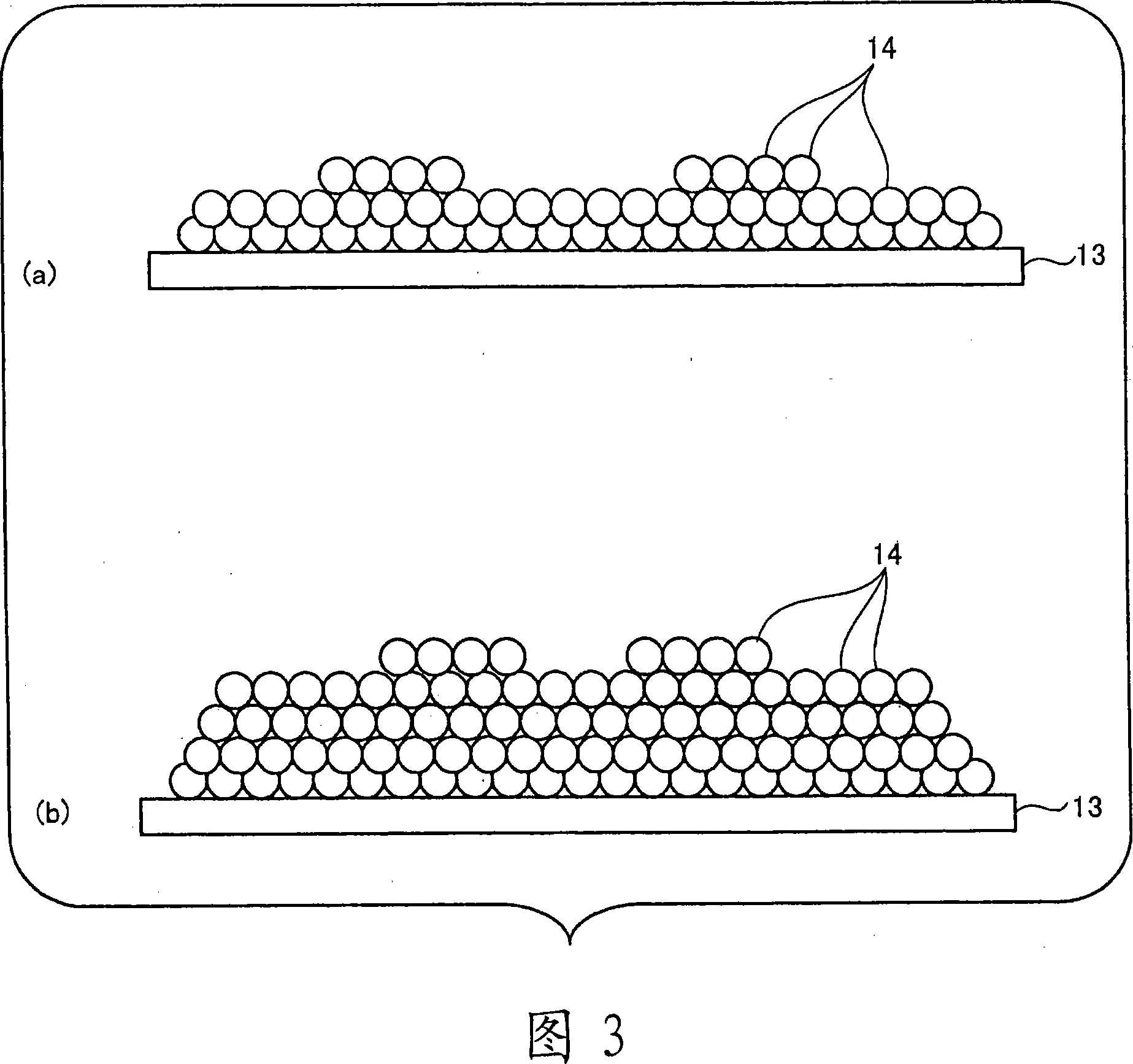

[0092] As explained with reference to FIG. 1, each 1-bit area 11a is obtained by filling minute holes piercing the disk with a magnetic material. The stamper preparation step (step S100) is a step of producing an imprint mold (stamper) for embossing a concave portion (cavity) on an aluminum substrate in a subsequent manufacturing step (step S200), which The recesses are forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com