Splicing laser interference lithography equipment suitable for large-area nanostructure fabrication

A spliced, large-area technology, used in microlithography exposure equipment, photolithographic process exposure devices, etc., can solve the problems of unstable exposure system, mobile platform is easily affected by gravity, etc., and achieve convenient movement and stable exposure system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

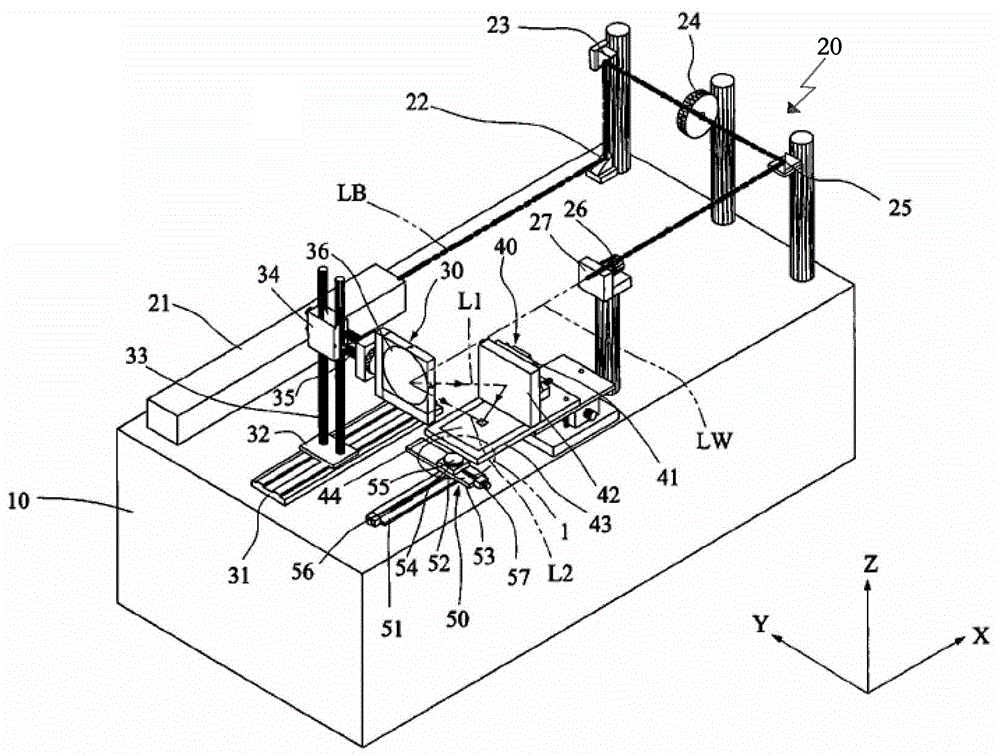

[0027] Such as figure 1 As shown, the present invention discloses a spliced laser interference lithography device suitable for the manufacture of large-area nanostructures. It consists of a main body 10 and a laser light wave supply unit 20 installed on the main body 10, a reflection mechanism 30, and an L-shaped fixing mechanism. 40 and substrate carrier 50.

[0028] The laser light wave supply unit 20 includes a laser light source generator 21, a shutter 24, a pinhole 26 and a lens 27, and the laser beam LB emitted by the laser light source generator 21 is emitted through the shutter 24, the pinhole 26 and the lens 27 to form laser light Wave LW. In order to make the structure of the whole device more compact, the laser light wave supply unit 20 also includes a first mirror 22, a second mirror 23 and a third mirror 25, and the first mirror 22 and the second mirror 23 are installed on the laser source generator 21 and the shutter 24. Between, the laser beam LB that laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com