Optical fibre grating three-dimensional acceleration /vibration sensor

A technology of vibration sensor and three-dimensional acceleration, which is applied in the field of sensors, can solve problems such as fiber grating space three-dimensional acceleration sensing that has not yet been developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

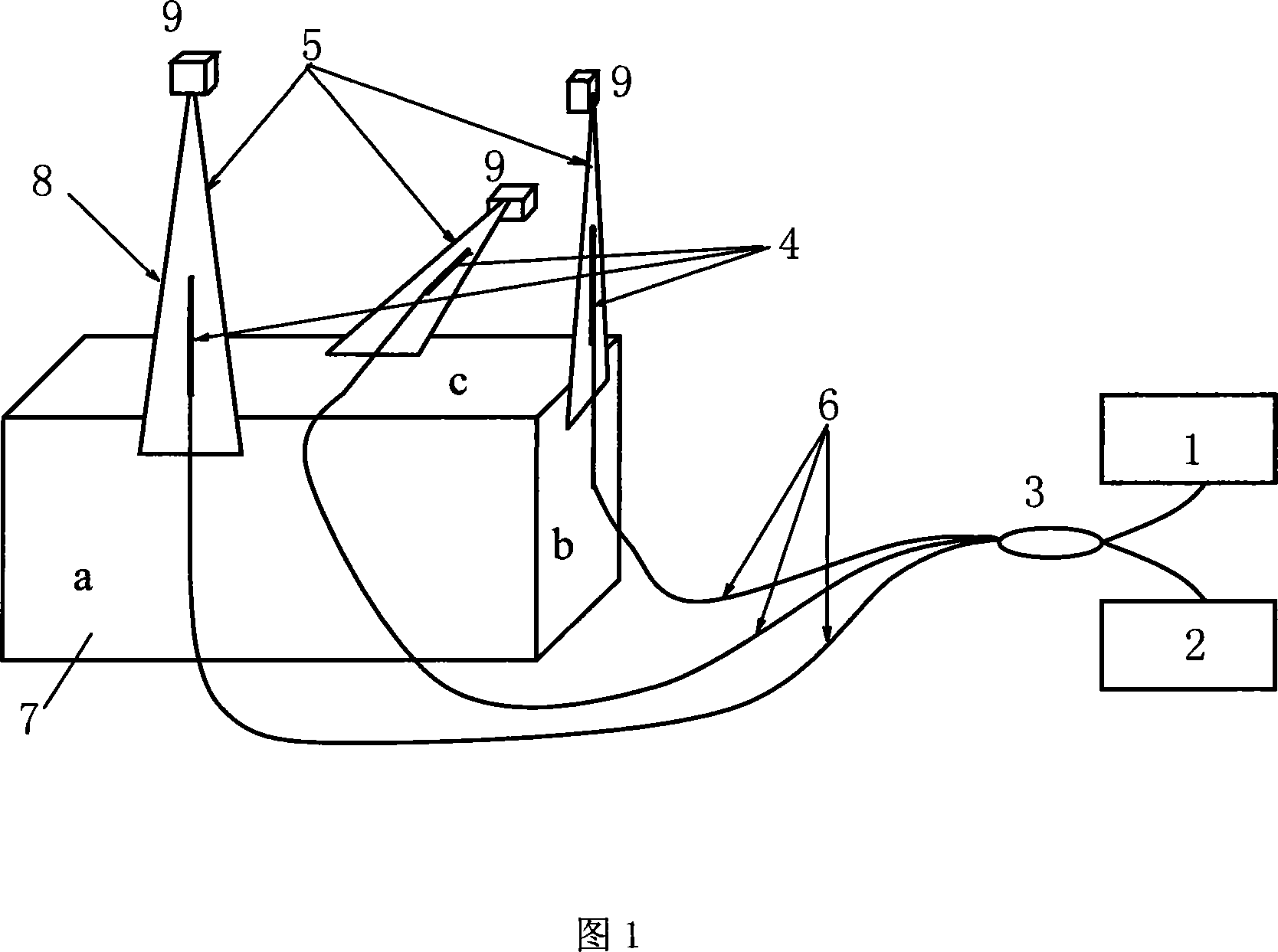

[0020] The fiber grating three-dimensional acceleration / vibration sensor of the present invention will be described in detail below in conjunction with the embodiments and drawings.

[0021] The fiber grating three-dimensional acceleration / vibration sensor provided by the present invention is composed of three vibrating beam structures with the same material and size, which are rigidly fixed on the same base in the three directions of x, y, and z axes, and the three vibrating beams are free Three identical mass blocks are rigidly fixed at the ends respectively, and three fiber gratings used as basic sensor devices are pasted on the upper surfaces of the three beams respectively. The positions of the three fiber gratings on the three beams are the same, and one end of the three fiber gratings is The optical splitter is respectively connected to the optical splitter through a single-mode fiber, and the other end of the optical splitter is respectively connected to the light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com