Motor position sensor

A sensor and motor technology, applied in the field of motor position sensors that change the winding structure, can solve the problems of destroying the structure of the axis A1, increasing the vibration coefficient, and repairing the damaged motor A, so as to reduce the cooperation of transformers and save maintenance Effects of cost and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

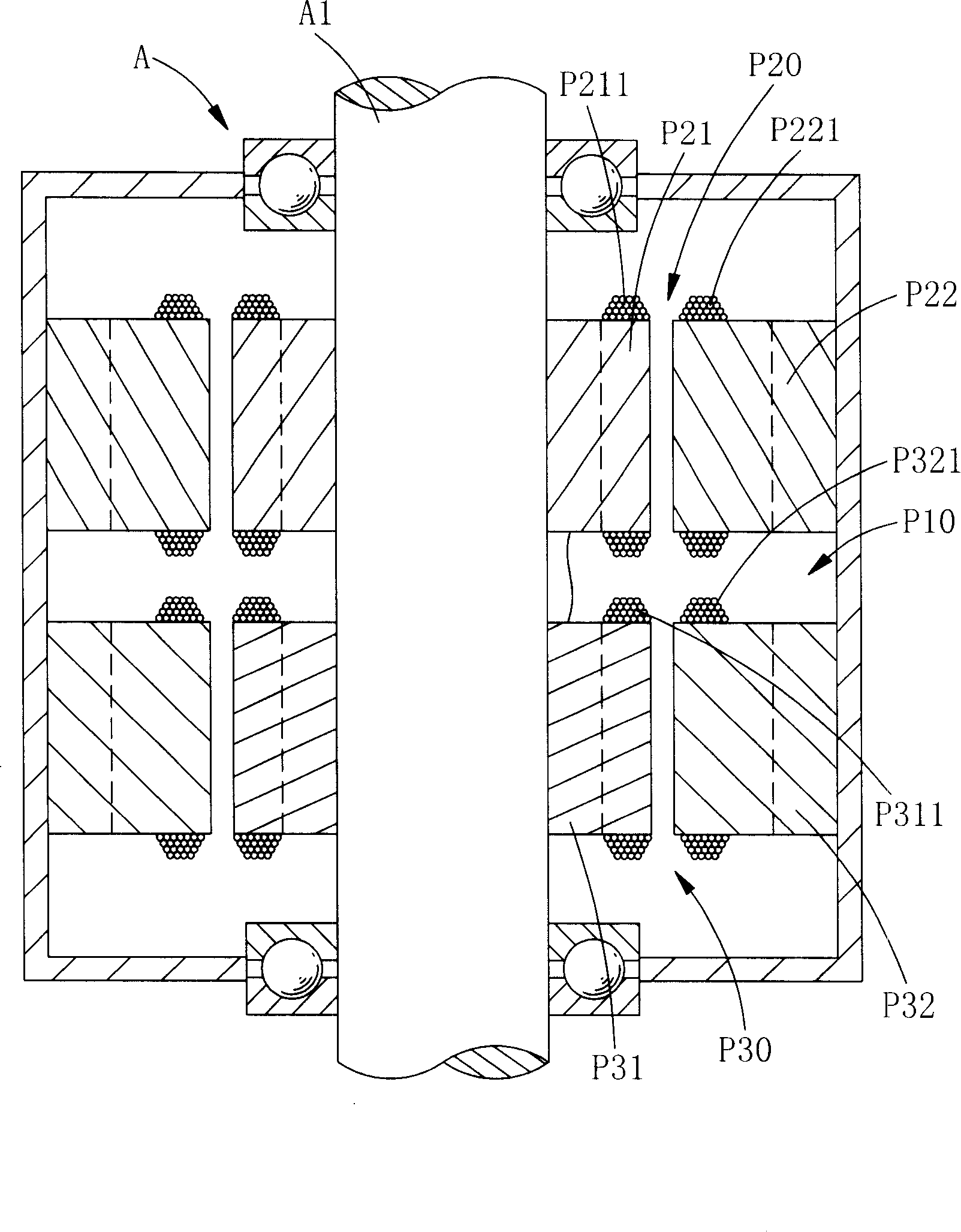

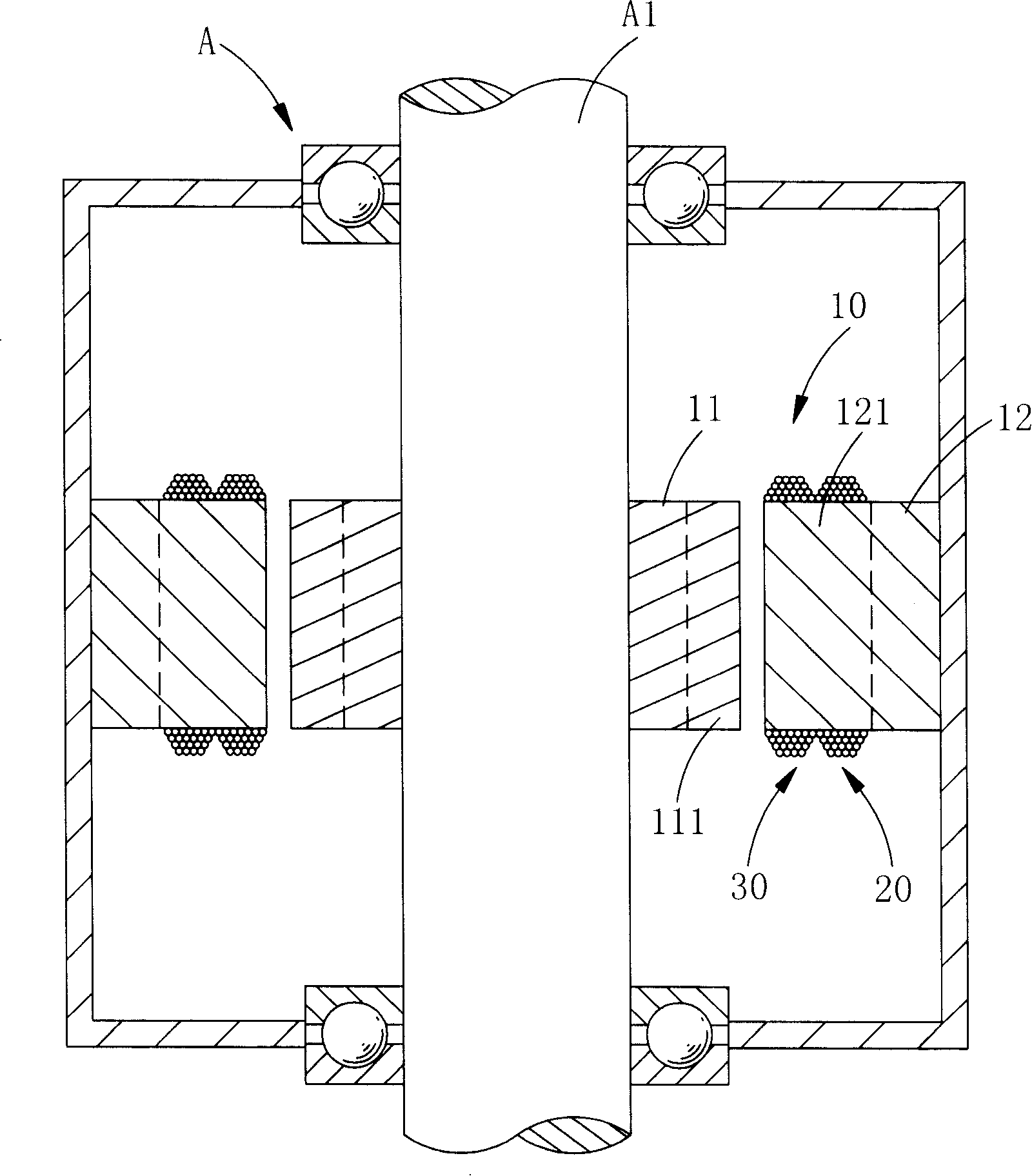

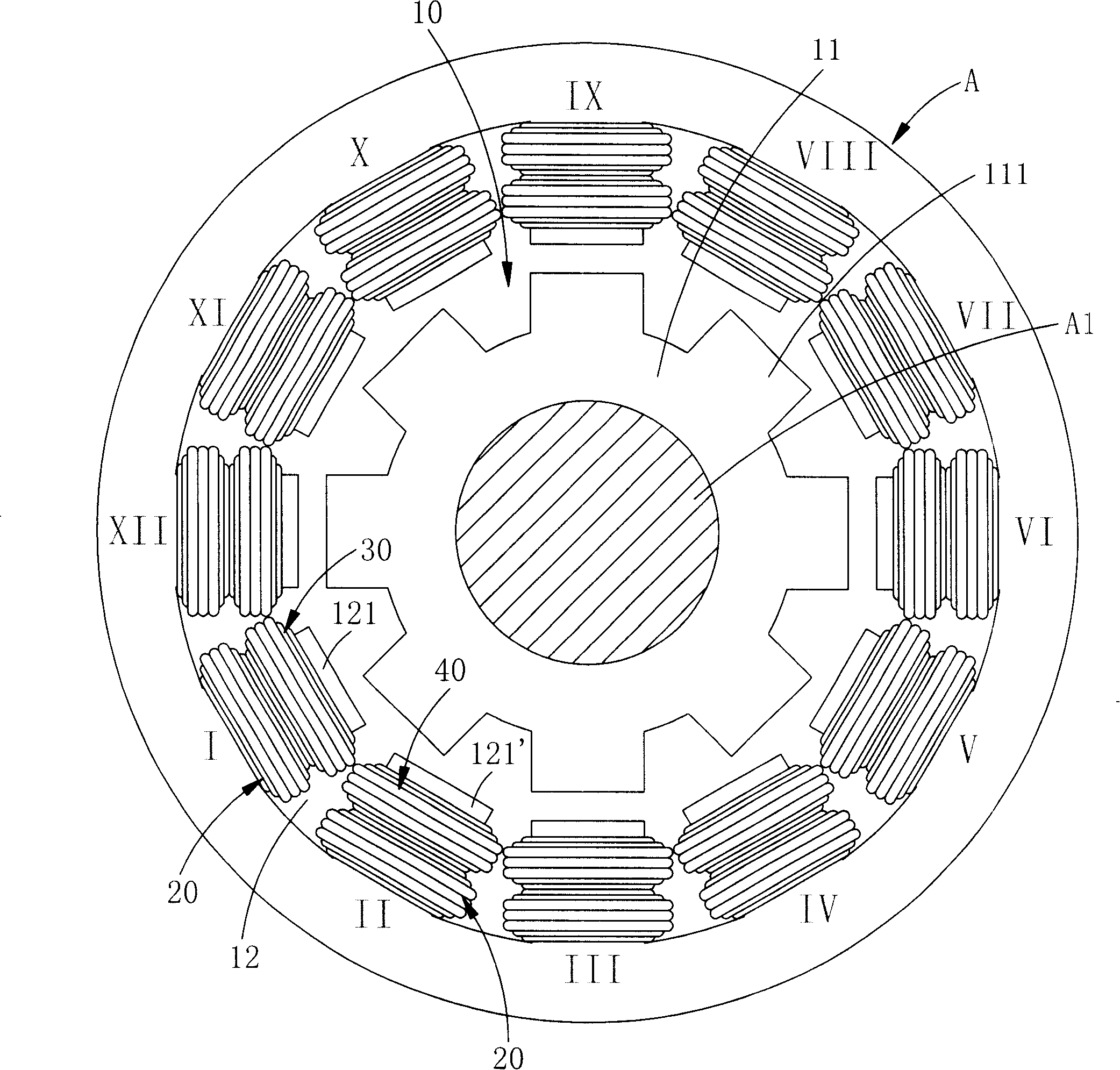

[0044] Please refer to the embodiment of the present invention figure 2 , image 3 Shown:

[0045] The motor position sensor of the present invention includes a resolver 10, a plurality of trigger coils 20, a plurality of sine coils 30 and a plurality of cosine coils 40; the resolver 10 is installed inside the motor A, and the resolver 10 includes a body 101, the The main body 101 includes a main body rotor 11 and a main body stator 12, the main body rotor 11 is annular, the main body rotor 11 is placed on the axis A1 of the motor A, and a plurality of rotor magnetic poles are set around the main body rotor 11 at equidistant intervals 111 The main body stator 12 is ring-shaped, and the main body stator 12 is fixed on the inner wall of the motor A, and a plurality of stator poles 121 are arranged at equal intervals around the main body stator 12; A set of trigger coils 20 is wound, and a set of sinusoidal coils 30 are wound adjacent to the trigger coils 20. A set of trigger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com