Device for detecting and maintaining mobile bridge structure

A bridge structure and maintenance device technology, which is applied in bridge maintenance, bridges, bridge parts, etc., can solve problems such as extended auxiliary time for bridge inspection and maintenance, failure to inspect and construct, and labor-intensive problems, so as to achieve safe and reliable construction operations and safe construction operations Good performance and simple cantilever structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

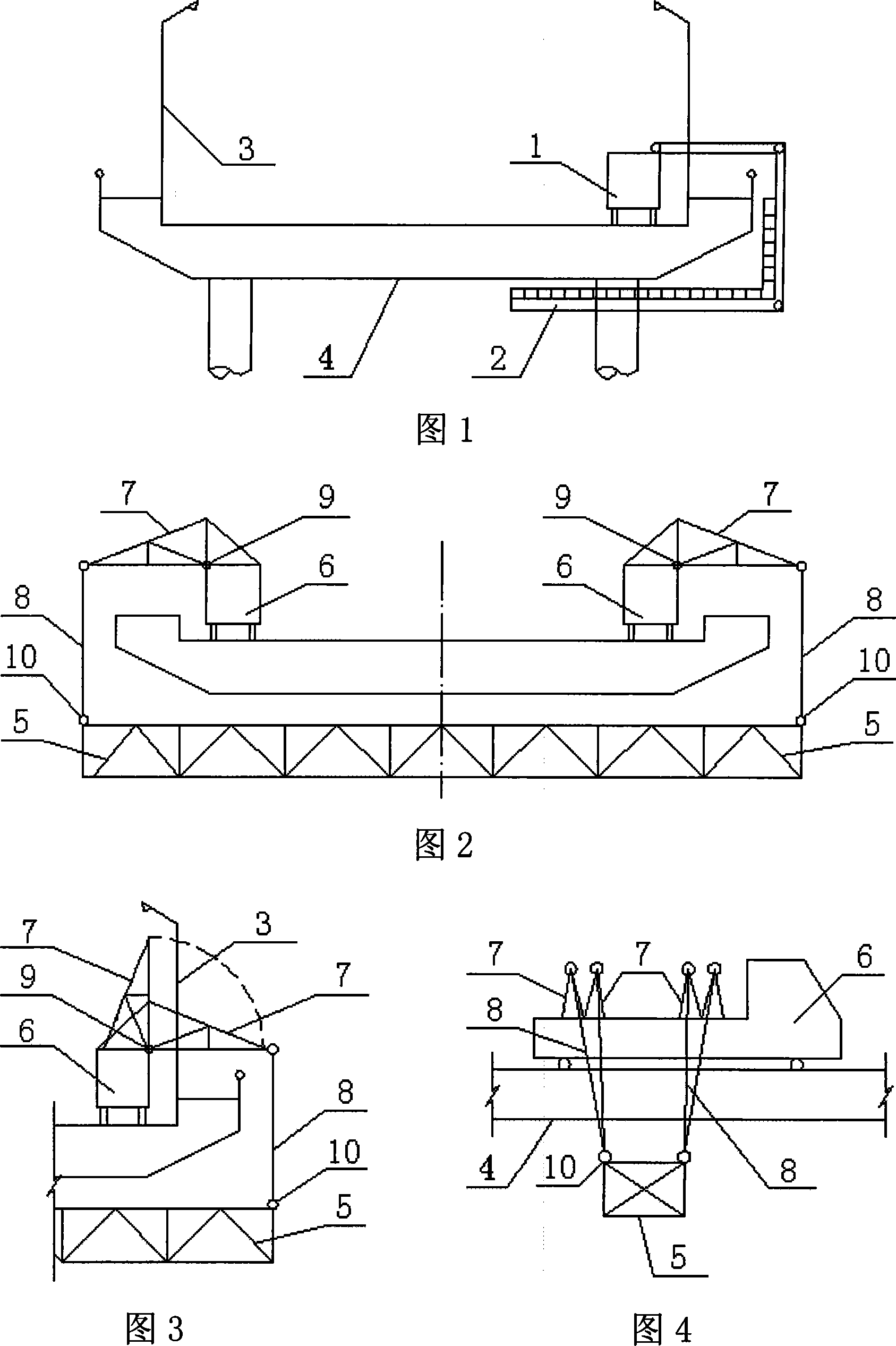

[0015] Referring to Fig. 2, Fig. 3, and Fig. 4, the mobile bridge structure detection and maintenance device of the present invention includes a counterweight truck 6, and there are two counterweight trucks 6, one side of the bridge deck corresponding to the counterweight truck 6 At least a three-leg cantilever frame 7 is articulated, and an overhaul platform 5 whose length corresponds to the width of the bridge deck is provided with two lifting points 10 on both sides of the width direction of the end of the overhaul platform 5 . Have suspension rope 8 to be connected with suspension point 10 on one end of maintenance platform 5. The cantilever frame 7 is a truss structure, and its shape is a right-angled triangle. Rope 8, or pulley is set on this end point, corresponding pulley is provided with suspension rope hoisting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com