Needle fin tube and plain tube mixedly arranged self-supporting type heat exchanger

A pin-fin tube, self-supporting technology, applied in heat exchanger types, indirect heat exchangers, fixed tubular conduit components, etc., can solve the problem of reducing the mass flow rate of effective flushing pin-fin tubes, and the limitation of heat transfer capacity of type heat exchangers , pin-fin tube and shell side bypass flow, etc., to achieve the effect of solving tube bundle oscillation, improving heat transfer coefficient, and increasing heat transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

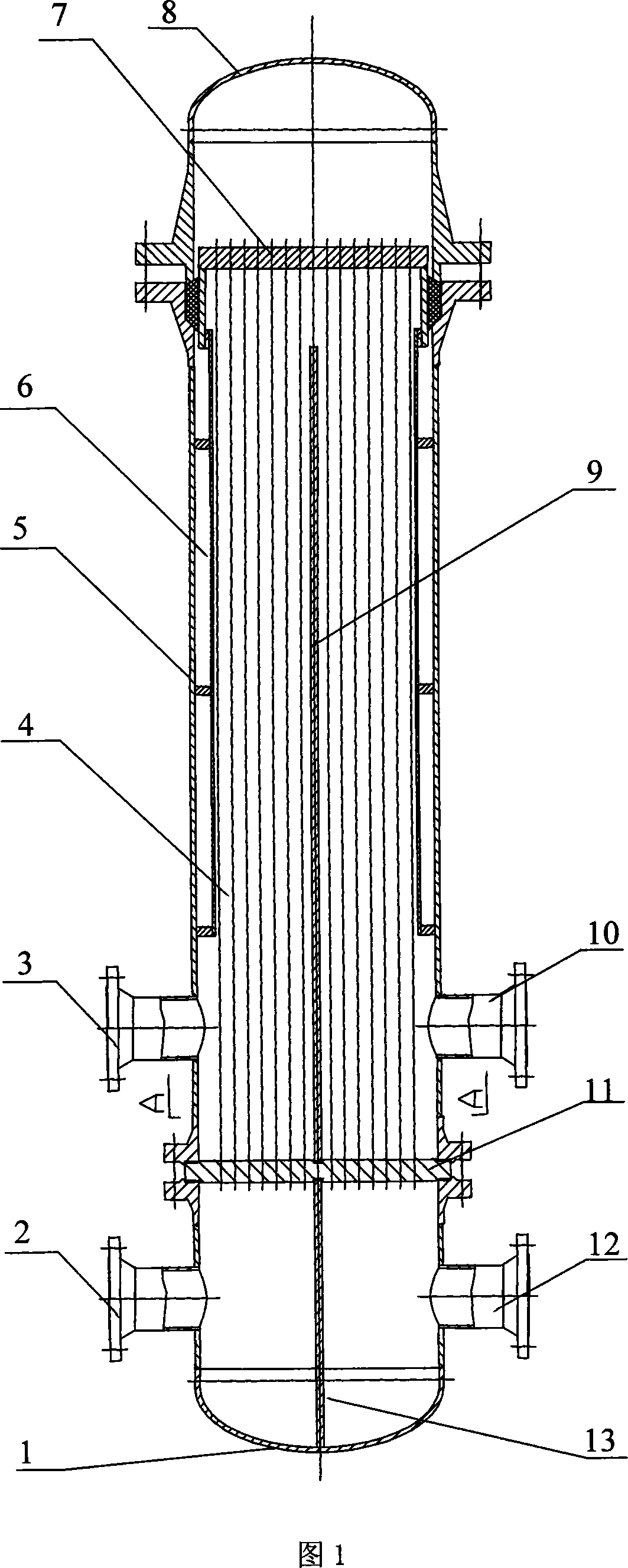

[0033] The present invention is described in more detail below in conjunction with accompanying drawing example:

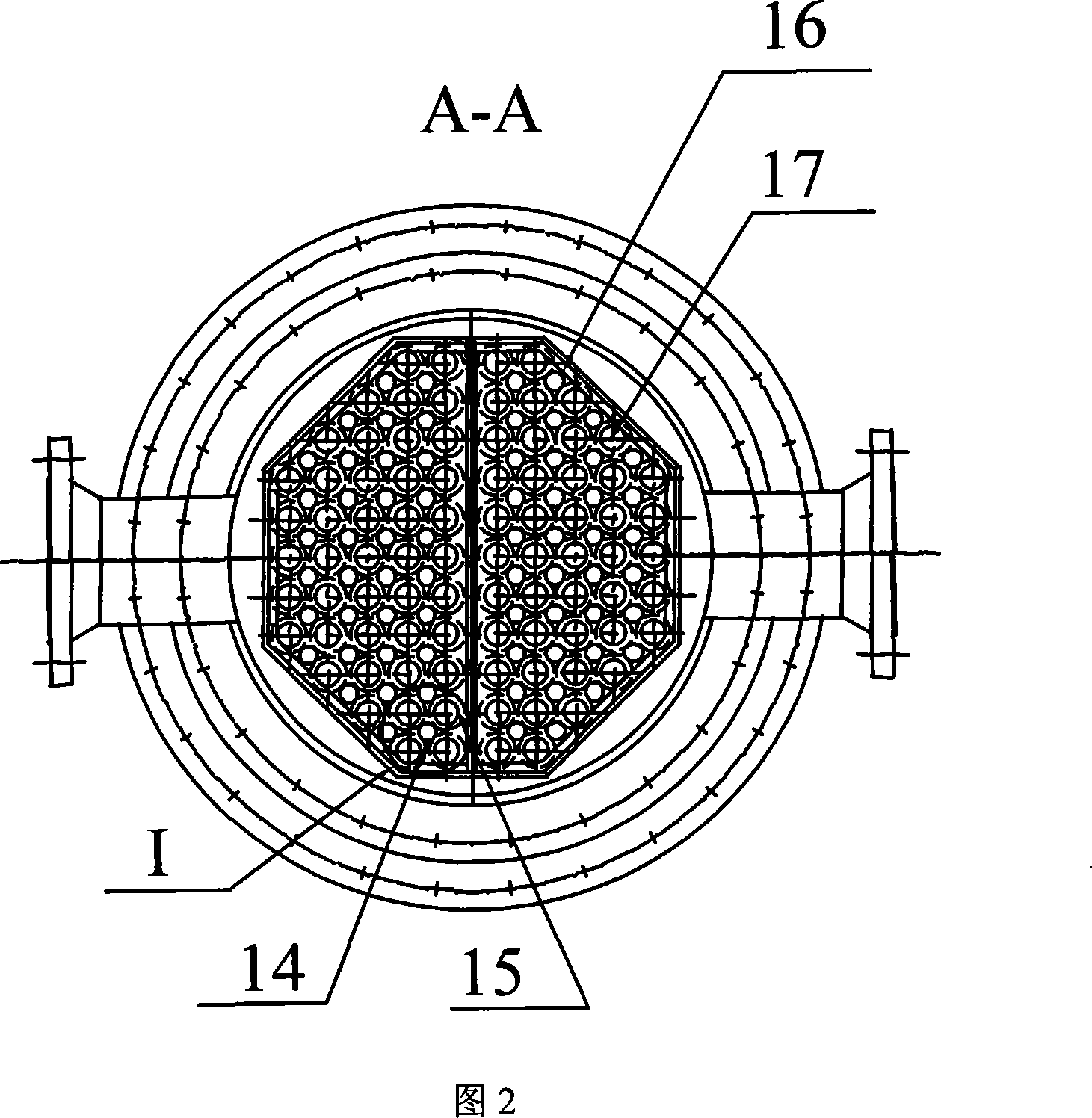

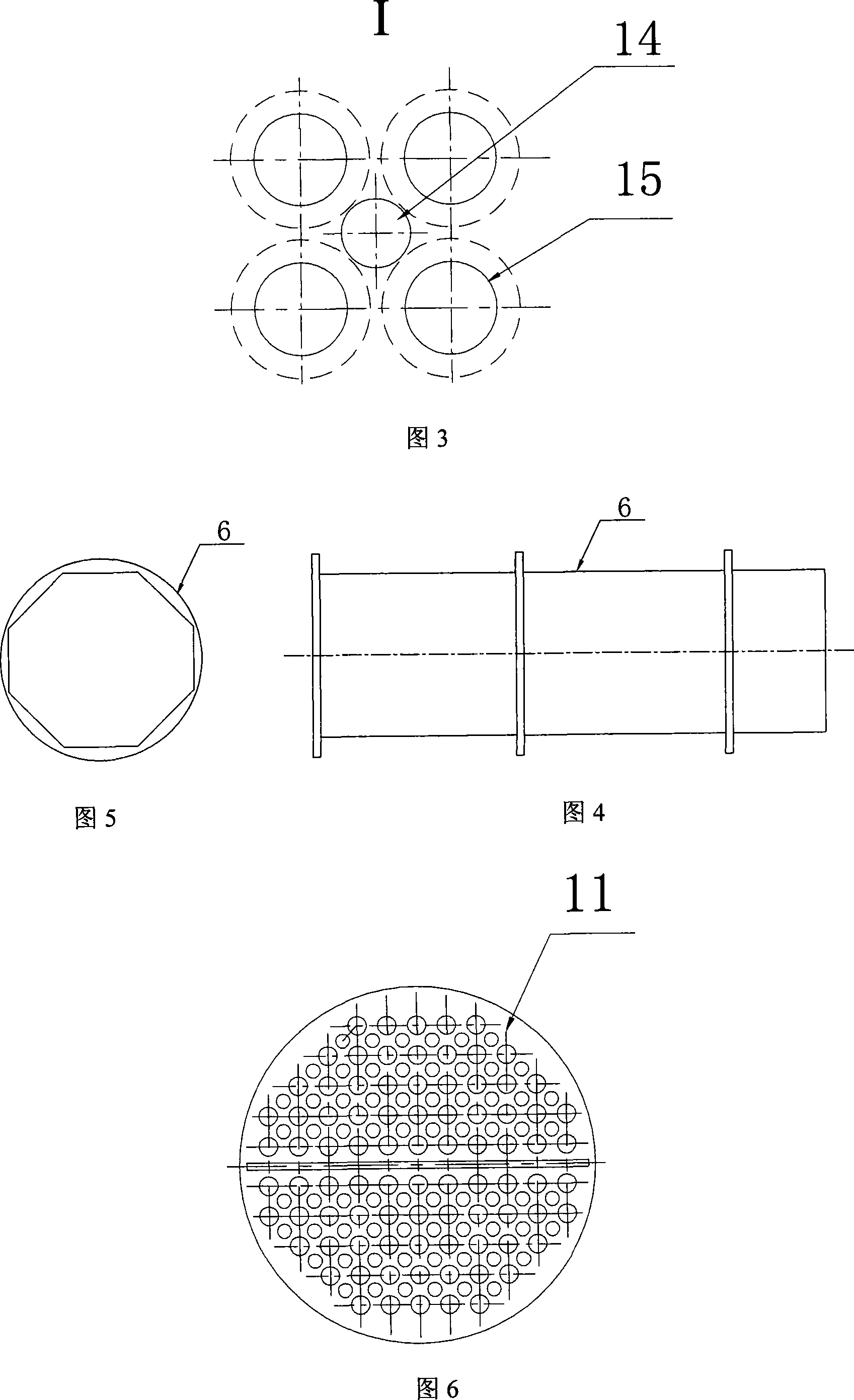

[0034] Combined with Figure 1, the self-supporting heat exchanger composed of pin-fin tubes and bare tubes is composed of a shell 3 and a tube bundle 4 installed in the shell. The two ends of the tube bundle are respectively installed on the fixed tube plate 11 and the floating head tube plate 7 , the fixed tube plate 11 is fixedly installed between the lower end of the shell and the tube box 1, the upper end of the shell 3 is equipped with an upper head 8, the shell has a shell side inlet 10 and a shell side outlet 3, and the tube box 1 has a The tube-side inlet 2 and the tube-side outlet 12, the tube bundle 4 is a mixed arrangement of bare tubes and pin-fin tubes with high-efficiency heat exchange capacity. Combined with Fig. 2 and Fig. 3 at the same time, the mixed arrangement of the light pipes and the pin-fin tubes with high-efficiency heat exchange capacity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com