Refraction and reflection projection optical system

A projection optical system, catadioptric technology, applied in the field of projection optical system, can solve the problems of optical processing, optical inspection difficulties, lack of imaging quality data, size design restrictions, etc., achieve long working distance, correct aberrations, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The catadioptric projection optical system of the present invention will be further described in detail below.

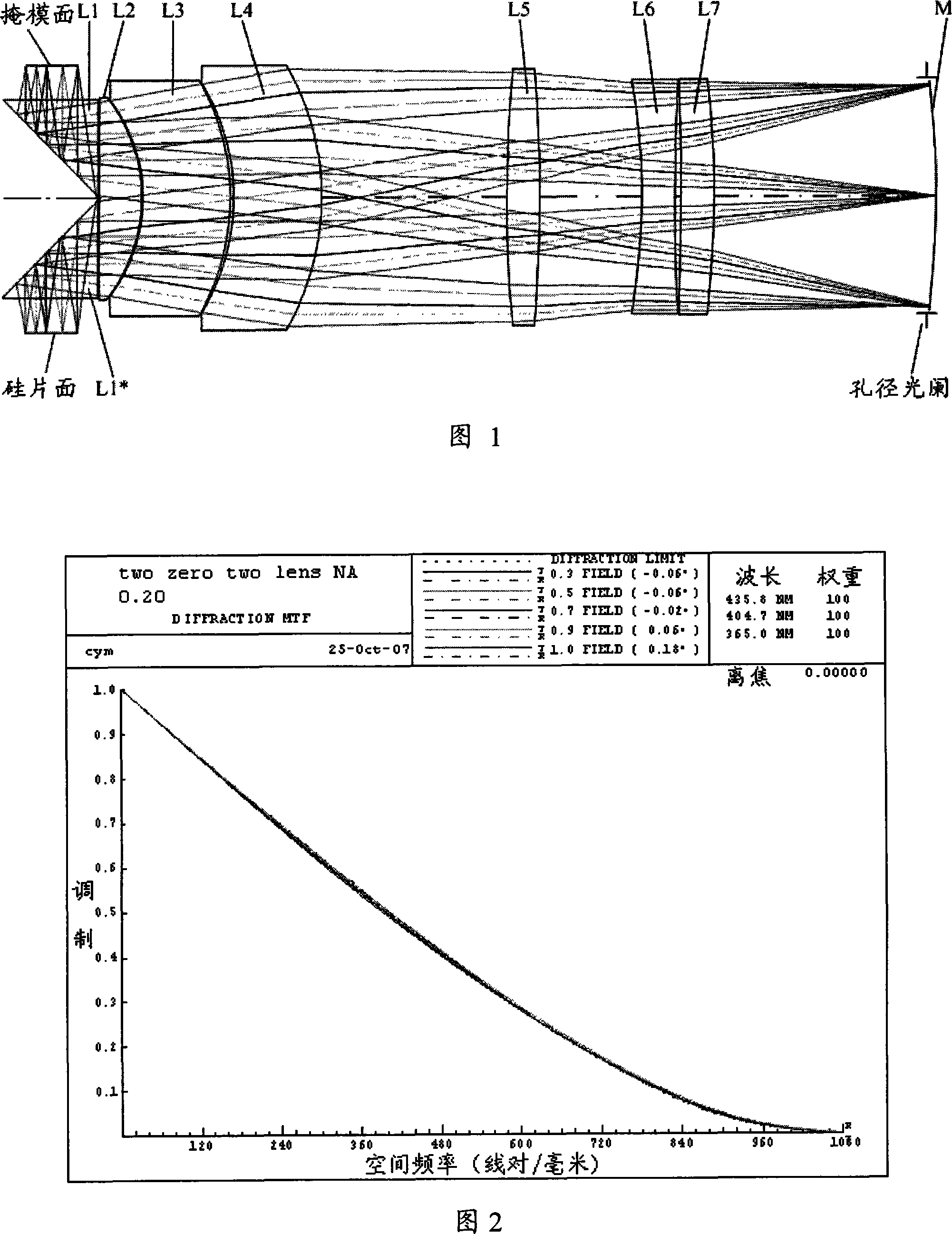

[0036] As shown in Figure 1, the present invention provides a catadioptric projection optical system, the projection optical system is a catadioptric symmetric structure, that is, from the side of the object plane, the front (rear) group is sequentially included, and the aperture stop is arranged. Concave spherical mirror M. Wherein, under the light reflection effect of the concave spherical mirror M, each lens assembly of the front group is each common assembly of the rear group, that is, the optical structure of the shared optical elements of the front (rear) group is completely symmetrical (surface Radius, spacing equal, optical material consistent), magnification is -1. The advantage of the symmetrical structure with a magnification of -1 is that according to the primary aberration theory, its vertical axis aberrations: coma, distortion, and chromatic ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com