Door sealing strip corner welding machine with automatic positioning equipment

An automatic positioning and positioning device technology, which is applied to household components, household appliances, and other household appliances, etc., can solve the problems of low product quality and production efficiency, and the door seal corner welding machine cannot realize fast and automatic positioning, so as to improve the welding quality , simple structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

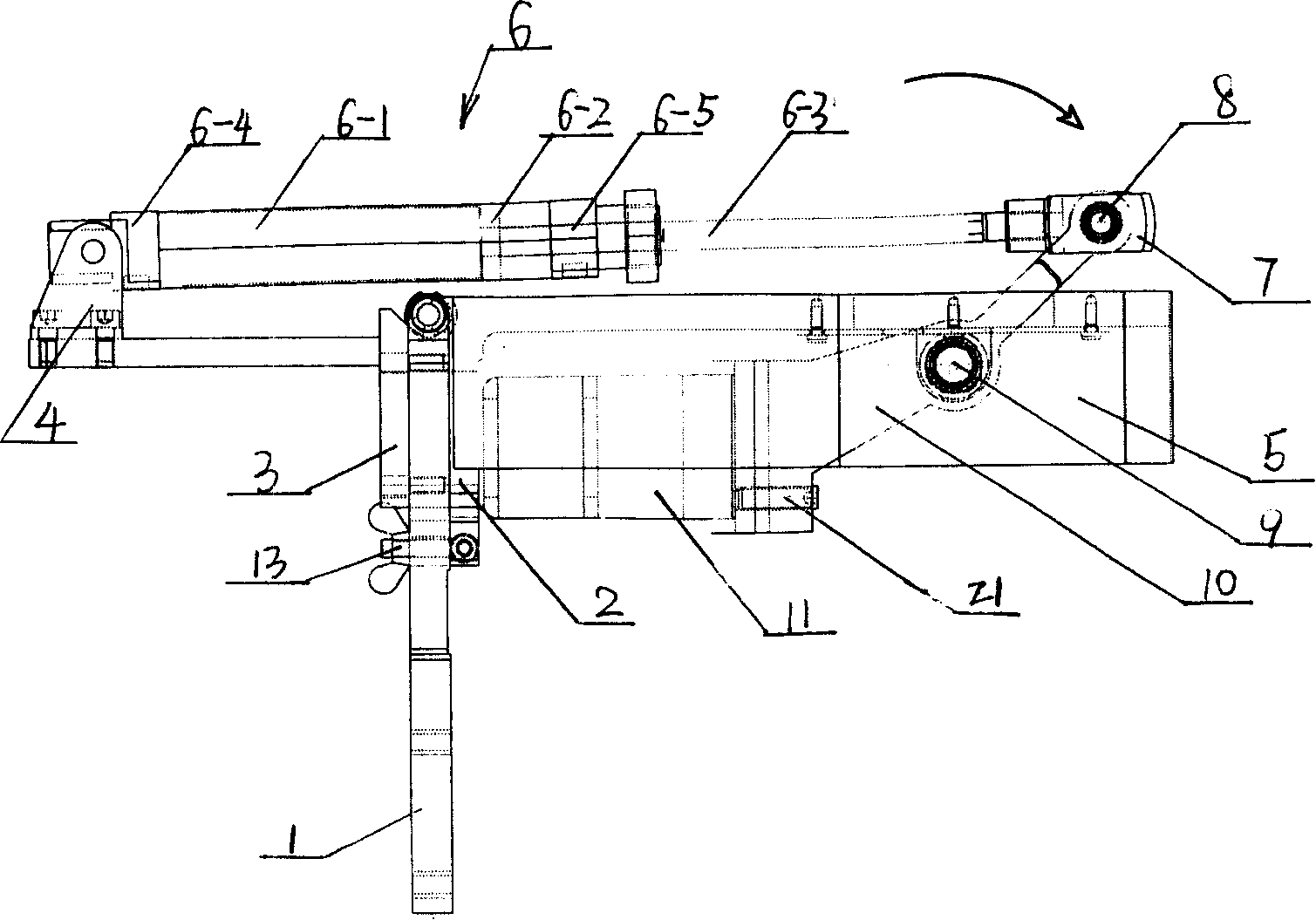

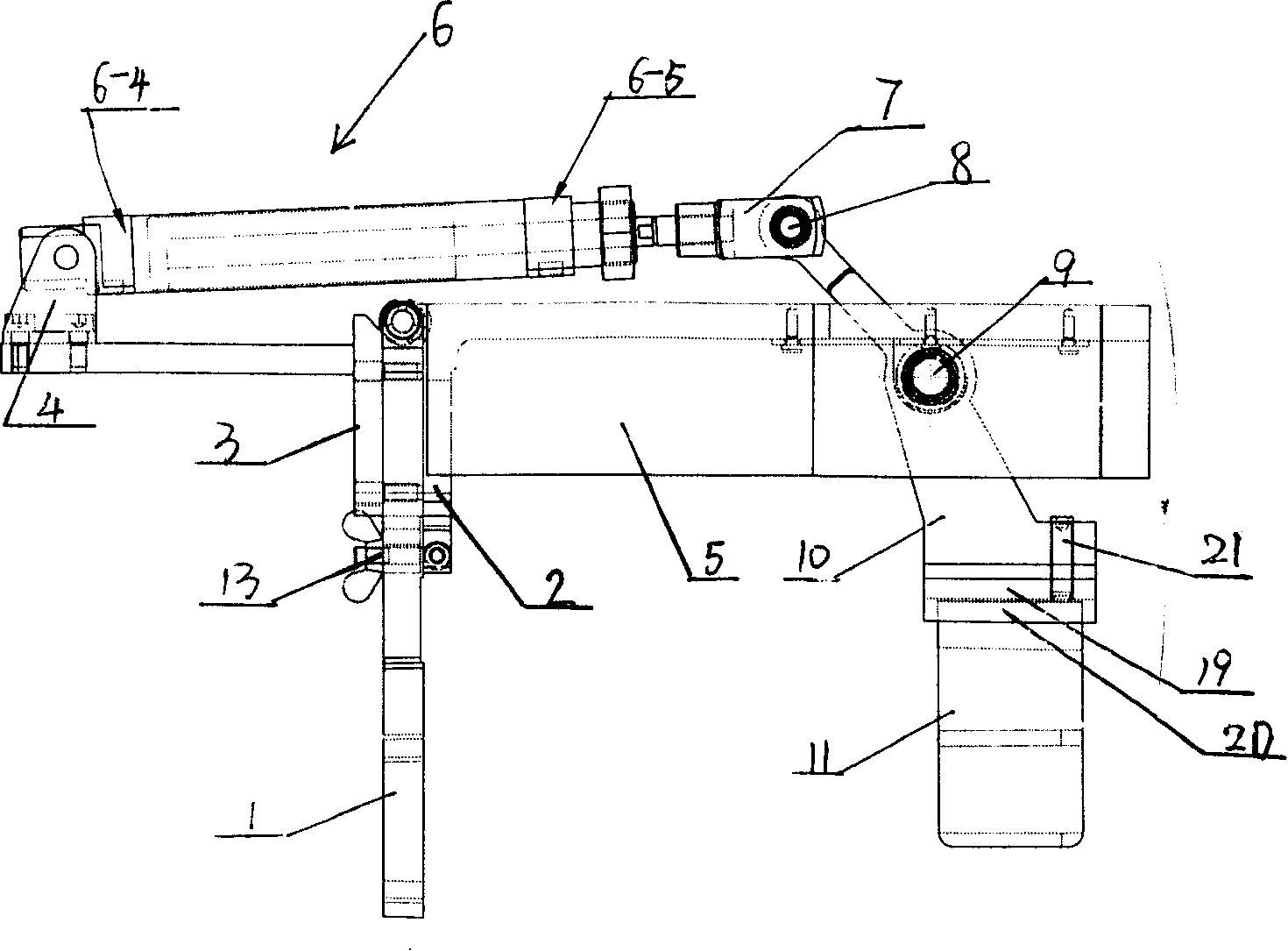

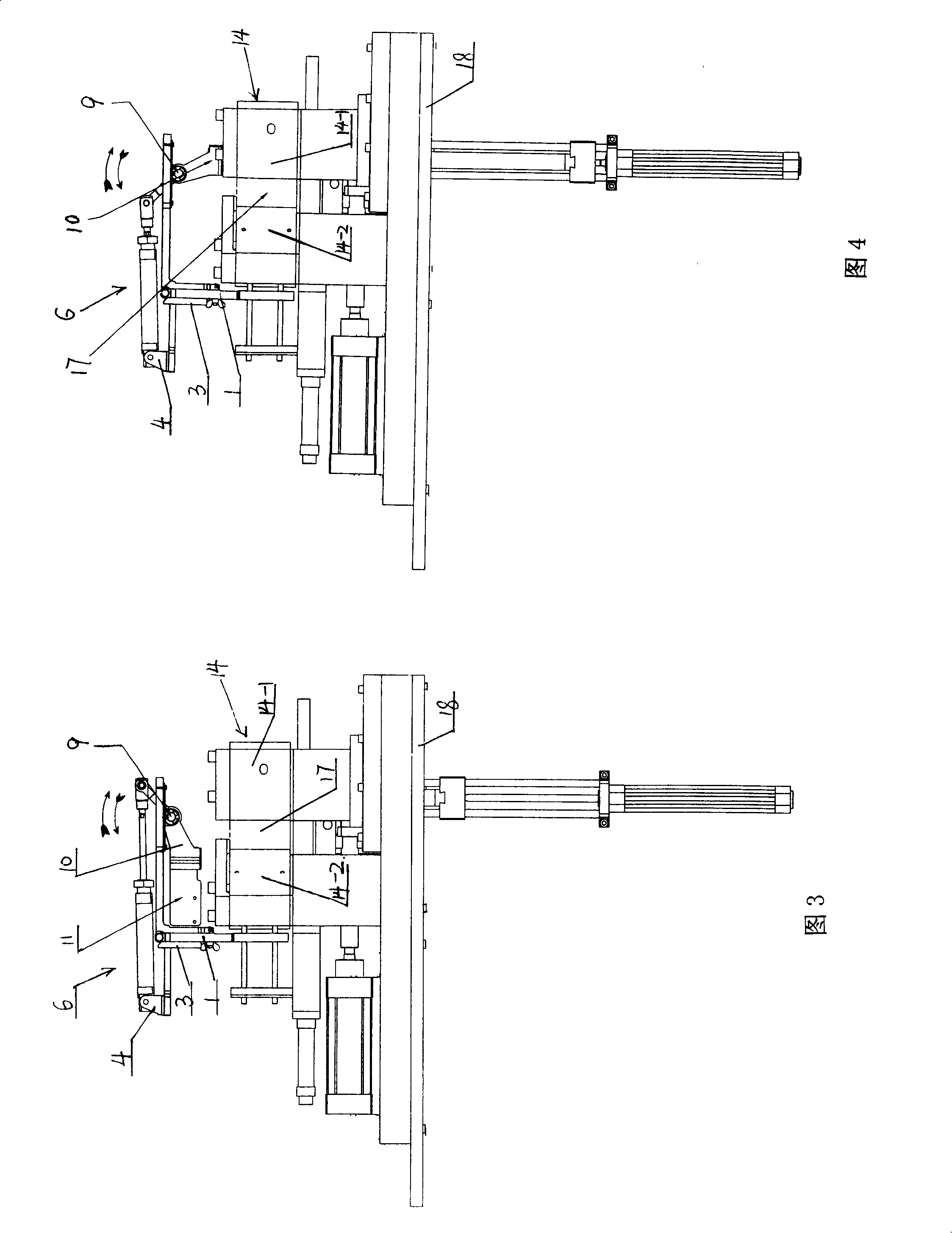

[0024] Embodiment one: if figure 1 and Figure 5 As shown, the door seal corner welding machine with automatic positioning device of the present invention includes a suction fume cover 5, a positioning device bottom plate 1 is provided on the corner welding machine platform 18, and a welding mold 15 includes a left welding mold 15-1 and a right welding mold 15-1. Welding mold 15-2;

[0025] The positioning device base plate 1 is provided with an automatic positioning device, and the automatic positioning device includes a cylinder assembly 6, and the cylinder assembly 6 includes a cylinder block 6-1, a piston 6-2, a piston rod 6-3, and a cylinder seat 3, The cylinder assembly 6 is provided with a forward air hole 6-4, a rear air inlet 6-5, and the front part of the piston rod 6-3 is provided with a connecting block 7, and the connecting block 7 is provided with a rotary shaft 8;

[0026] The suction fume hood 5 is provided with a positioning block rotating bracket 10, the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com