Method for processing gas port of engine cylinder cover

A technology of engine cylinder head and processing method, which is applied in the direction of engine components, machines/engines, cylinder heads, etc., can solve problems affecting airflow organization, engine intake volume, airflow organization and intake efficiency, etc., and achieve high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

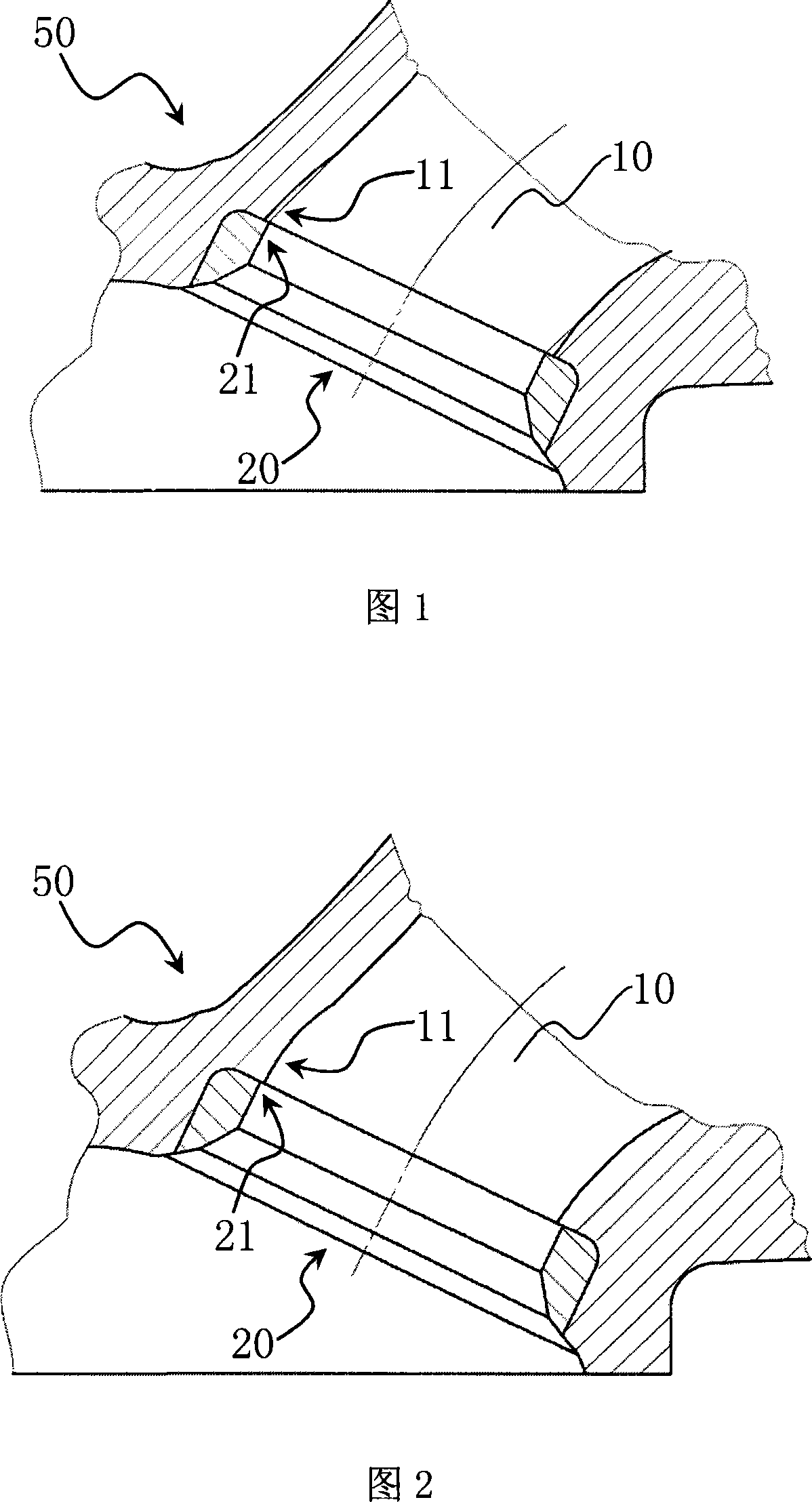

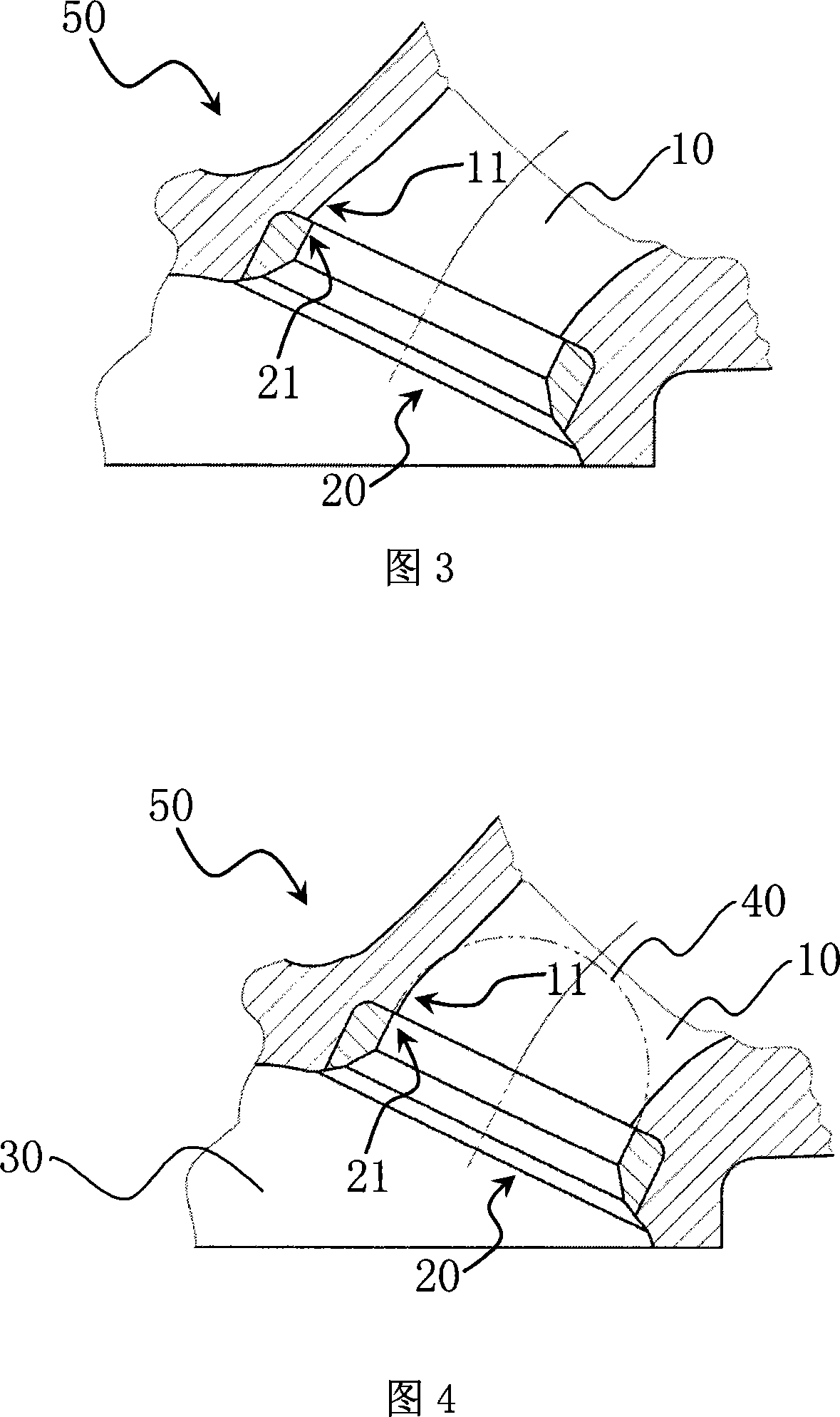

[0013] As shown in Figure 4, the processed cylinder head is fixed on the processing equipment, and the valve seat is placed at the opening of the air channel leading to the combustion chamber and installed in place. The wall surface of the air channel away from the opening is cast, and then Use cutting tools to precisely process the throat at the connection between the air passage and the top opening of the valve seat, and make the radius of gyration of the cutting trajectory of the tool equal to the inner diameter of the opening at the top of the valve seat, and the cutting trajectory intersects with the air passage A smooth curved surface can be obtained, that is, a smooth transition between the top opening of the processed valve seat and the throat of the airway.

[0014] As a preferred solution of the present invention, the cutting tool is extended from the combustion chamber into the throat where the airway port communicates with the top opening of the valve seat and is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com