Light source module and backlight unit

A light source module and light-emitting element technology, which is applied in the direction of light source, electric light source, optical element, etc., can solve the problems of light-emitting wavelength shift, light-emitting diode light-emitting efficiency reduction, and affect the display quality of liquid crystal display, etc., to achieve good heat dissipation efficiency and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

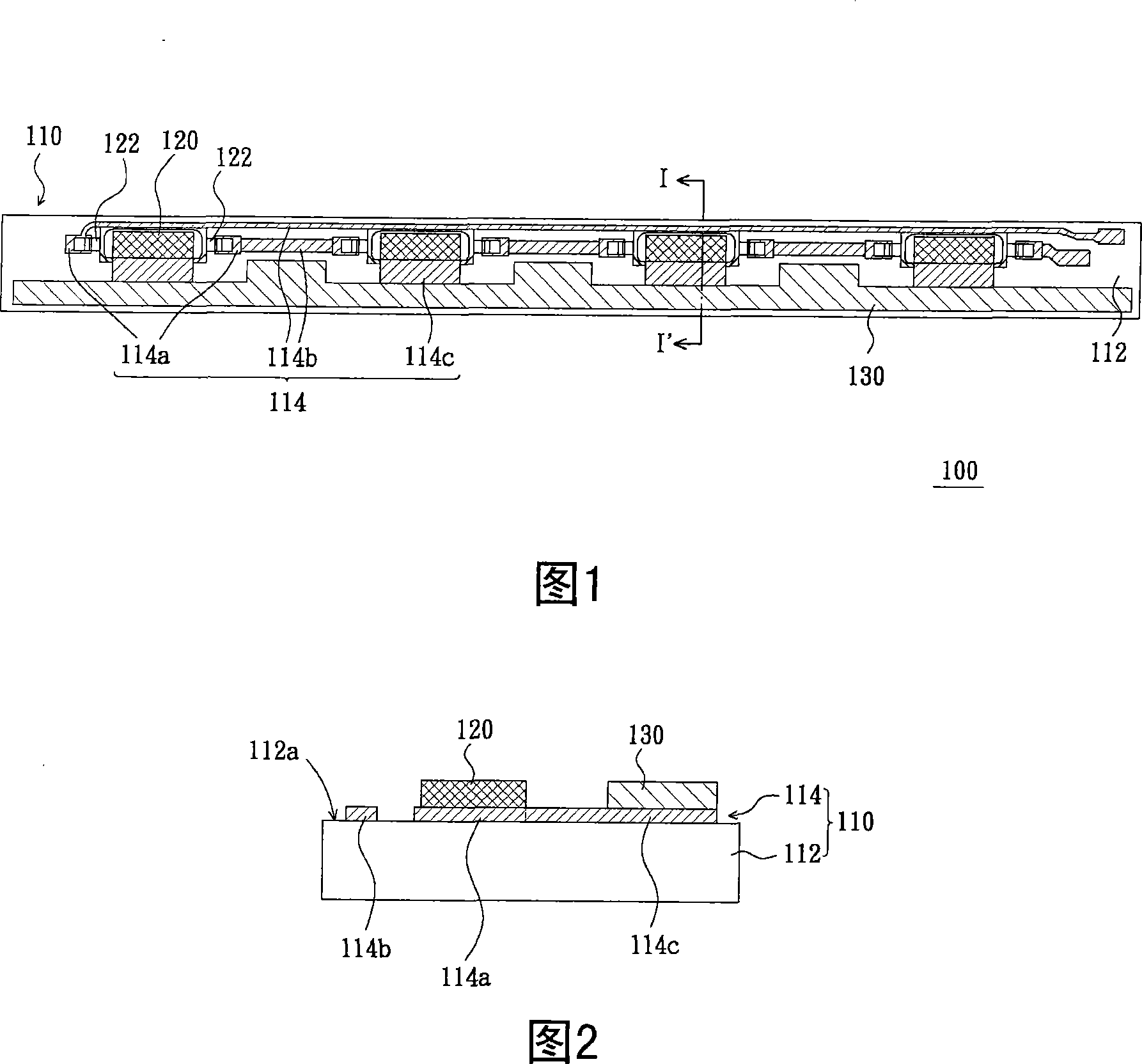

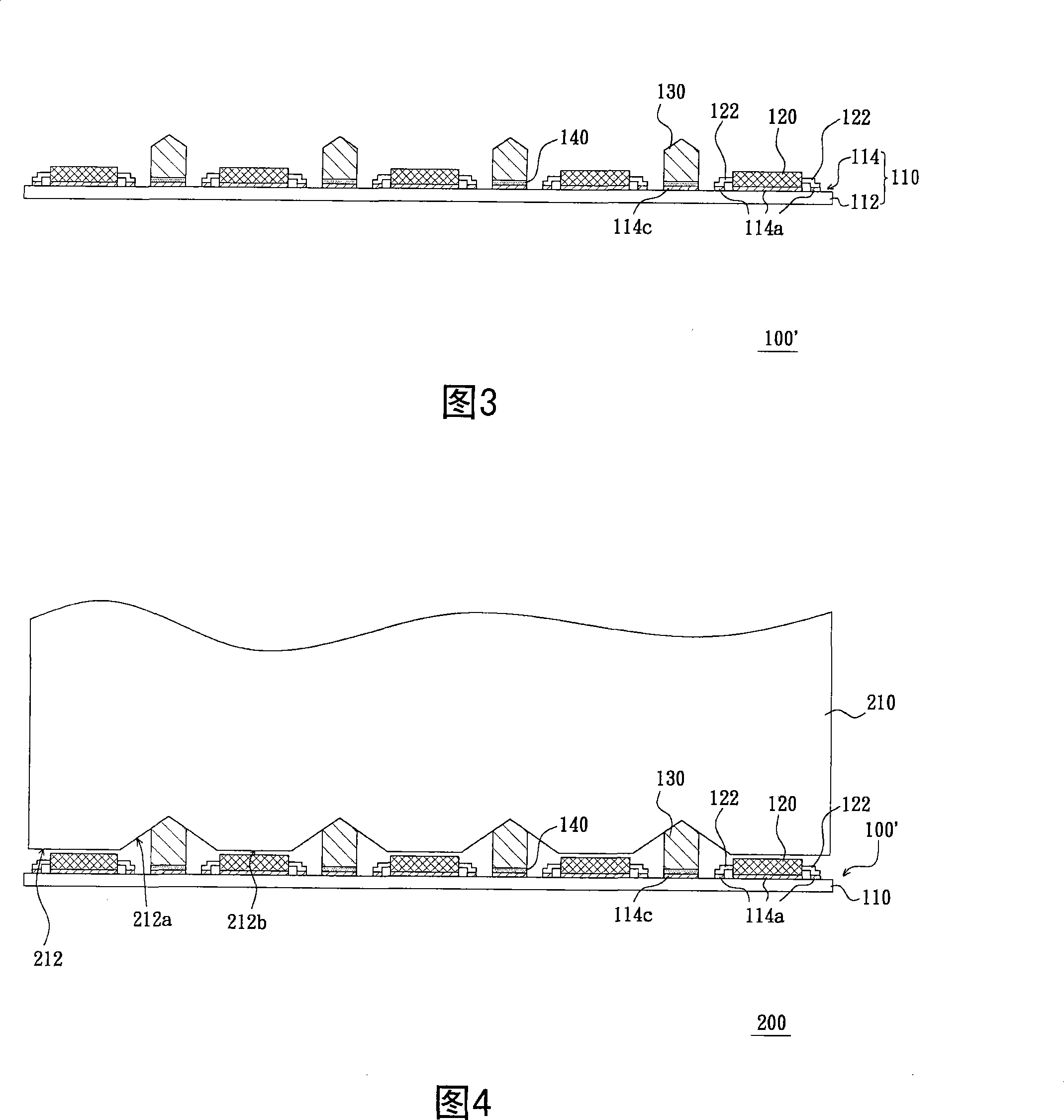

[0042] Fig. 1 is a top view of a light source module according to an embodiment of the present invention, and Fig. 2 is a schematic cross-sectional view along line I-I' of Fig. 1 . Referring to FIG. 1 and FIG. 2 , the light source module 100 of this embodiment includes a circuit board 110 , a plurality of light emitting elements 120 and a heat dissipation element 130 . The circuit board 110 has a patterned metal layer 114. Furthermore, in this embodiment, the circuit board 110 includes a substrate 112, and the substrate 112 has a bearing surface 112a, and the patterned metal layer 114 is disposed on the bearing surface 112a. The patterned metal layer 114 includes a plurality of connection portions 114a and pattern lines 114b, and the pattern lines 114b are connected to the connection portions 114a. The light emitting elements 120 are respectively disposed on one of the connecting portions 114a. The heat dissipation element 130 is disposed on the circuit board 110 and contacts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com