Zoom lens

A zoom lens and lens technology, applied in the field of zoom lenses, can solve the problems of high production cost, large relative aperture, and difficulty in achieving zoom lenses, and achieve good zoom effects, improved aberrations, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

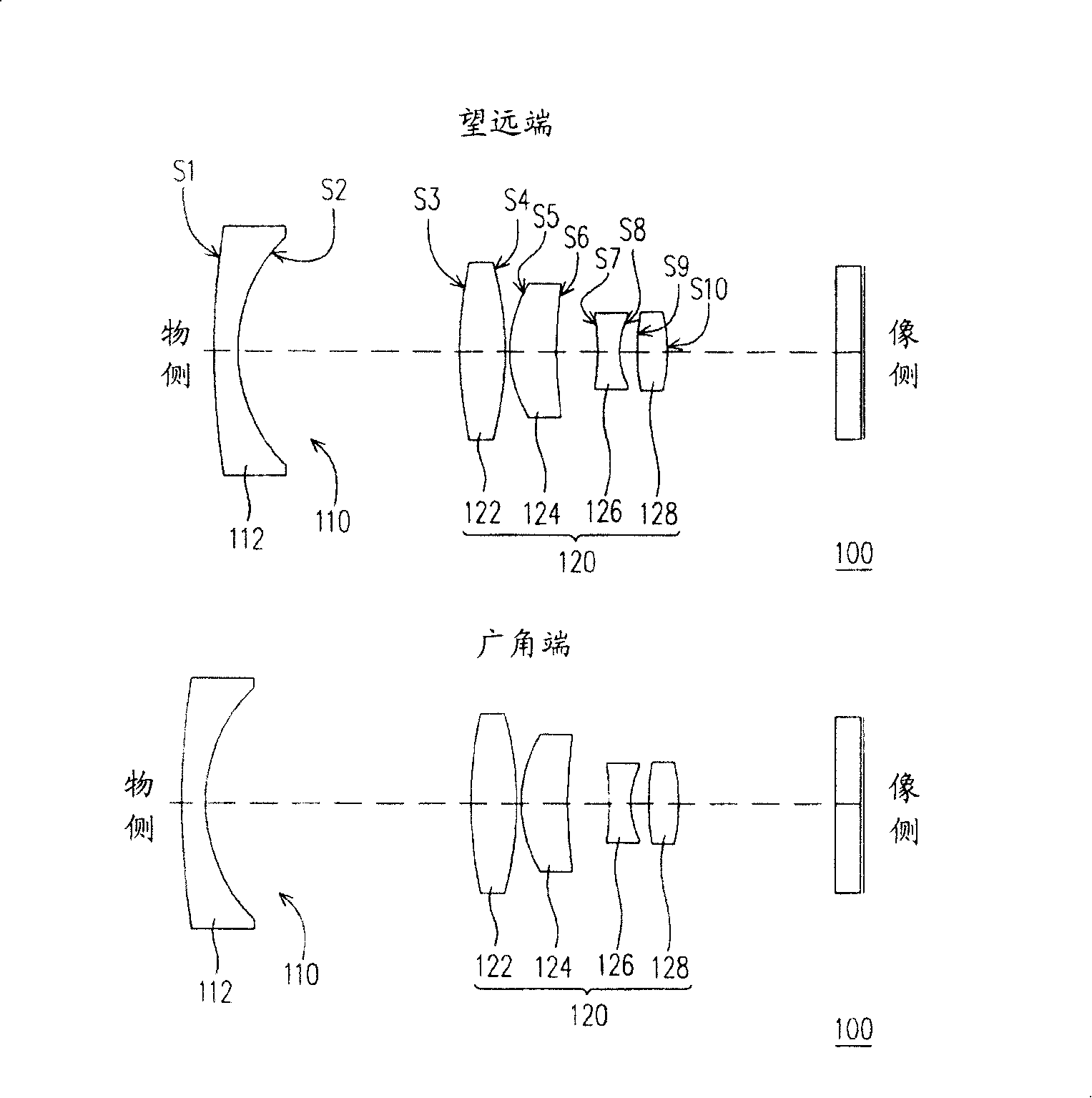

[0021] figure 1 It is a schematic diagram of a zoom lens in an embodiment of the present invention at the wide-end (wide-end) and the tele-end (tele-end), wherein figure 1 The upper part is a schematic diagram of the zoom lens at the telephoto end, while figure 1 The bottom half is a schematic diagram of the zoom lens at the wide-angle end. Please refer to figure 1 , the zoom lens 100 of this embodiment includes a first lens group 110 with negative diopter and a second lens group 120 with positive diopter, wherein the second lens group 120 is disposed between the first lens group 110 and an image side between. In addition, the first lens group includes a first lens 112 with a negative diopter, and the first lens 112 is a meniscus lens with a convex surface facing the object side, and its Abbe number is greater than 50. In addition, the zoom lens 100 satisfies the following conditions: (1) -0.6<F / F1<-0.2; (2) 0.7<R2 / F<1.8, wherein F is the focal length of the zoom lens 100,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com