Method for controlling a moveable tool, apparatus and mechanical tool

A technology for moving tools and mechanical tools, applied in manufacturing tools, general control systems, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

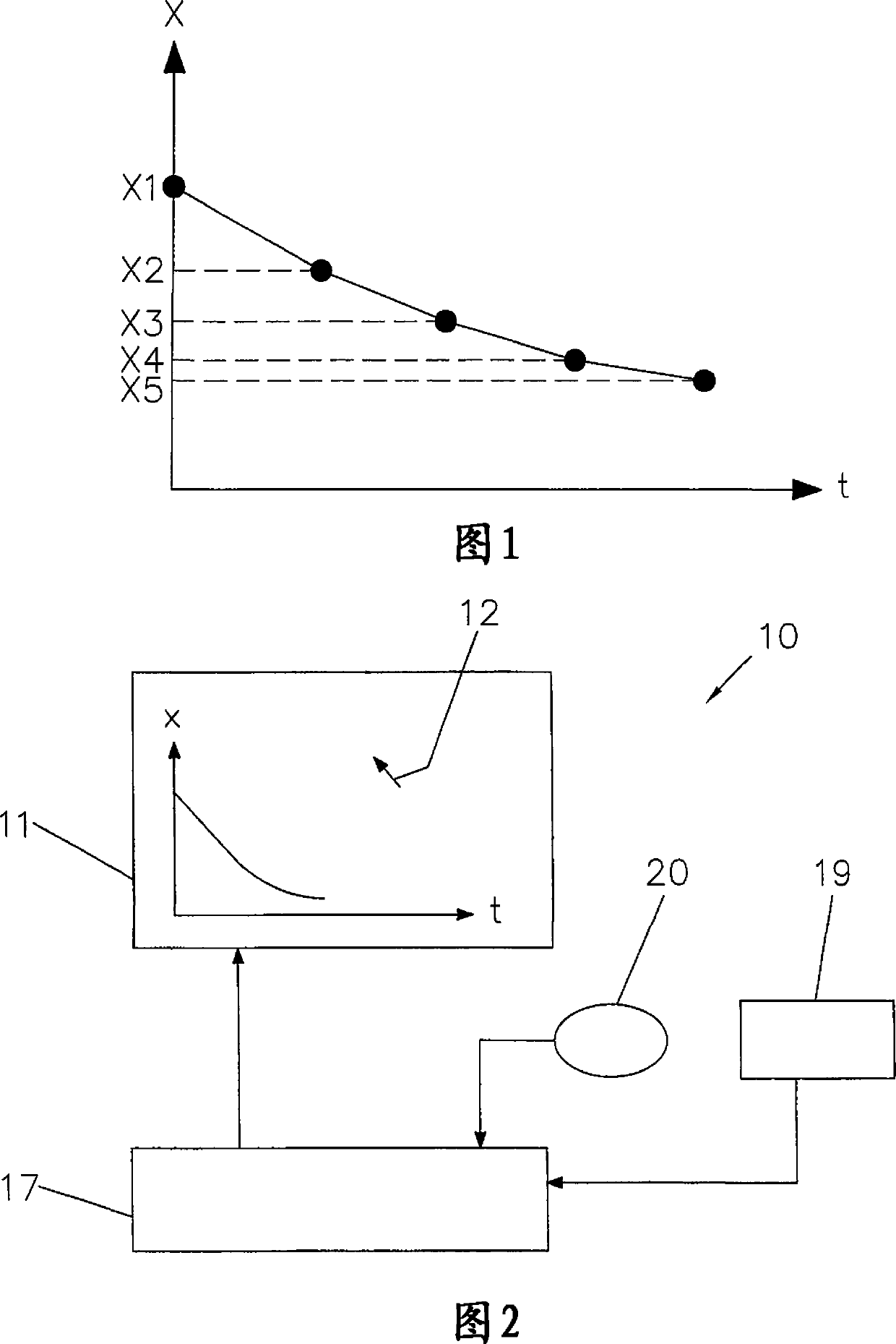

[0020] Figure 1 shows a graph of a known type of feed function. The abscissa t corresponds to the time axis, and the ordinate x specifies the position of the tool on the x-axis.

[0021] In order to determine the feed function, for the positions X1, X2, X3, X4, X5 of the tool and between the positions of the tool, i.e. between X1 and X2, between X2 and X3, between X3 and X4 and between X4 and X5 Each travel speed V1, V2, V3, V4 of the inter-movement specifies a value respectively. If the tool is e.g. a grinding wheel, X1 corresponds to the contact position, e.g. where the tool hits the workpiece surface, X2 corresponds to the first transition position from which material is removed by roughing, X3 corresponds to the second transition position, where material is removed from this second transfer position by semi-finishing, X4 corresponds to a third transfer position from which fine-finishing begins, and X5 corresponds to the final position of the tool to obtain finished dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com