Ink jet box regenerating method

A technology for ink cartridges and inkjet printers, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of achieving design capacity, environmental pollution, and difficulty in ink injection, and ensure integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

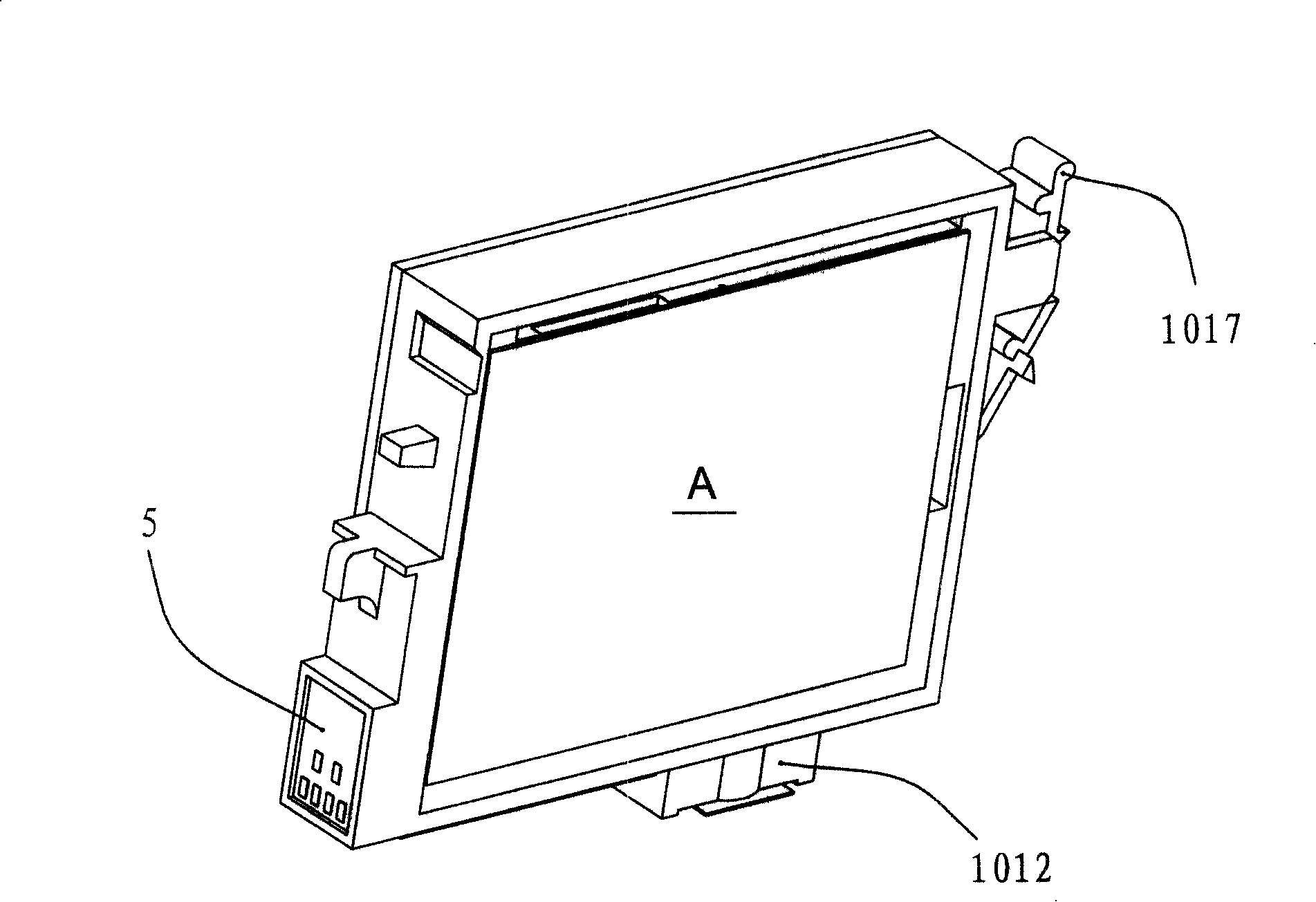

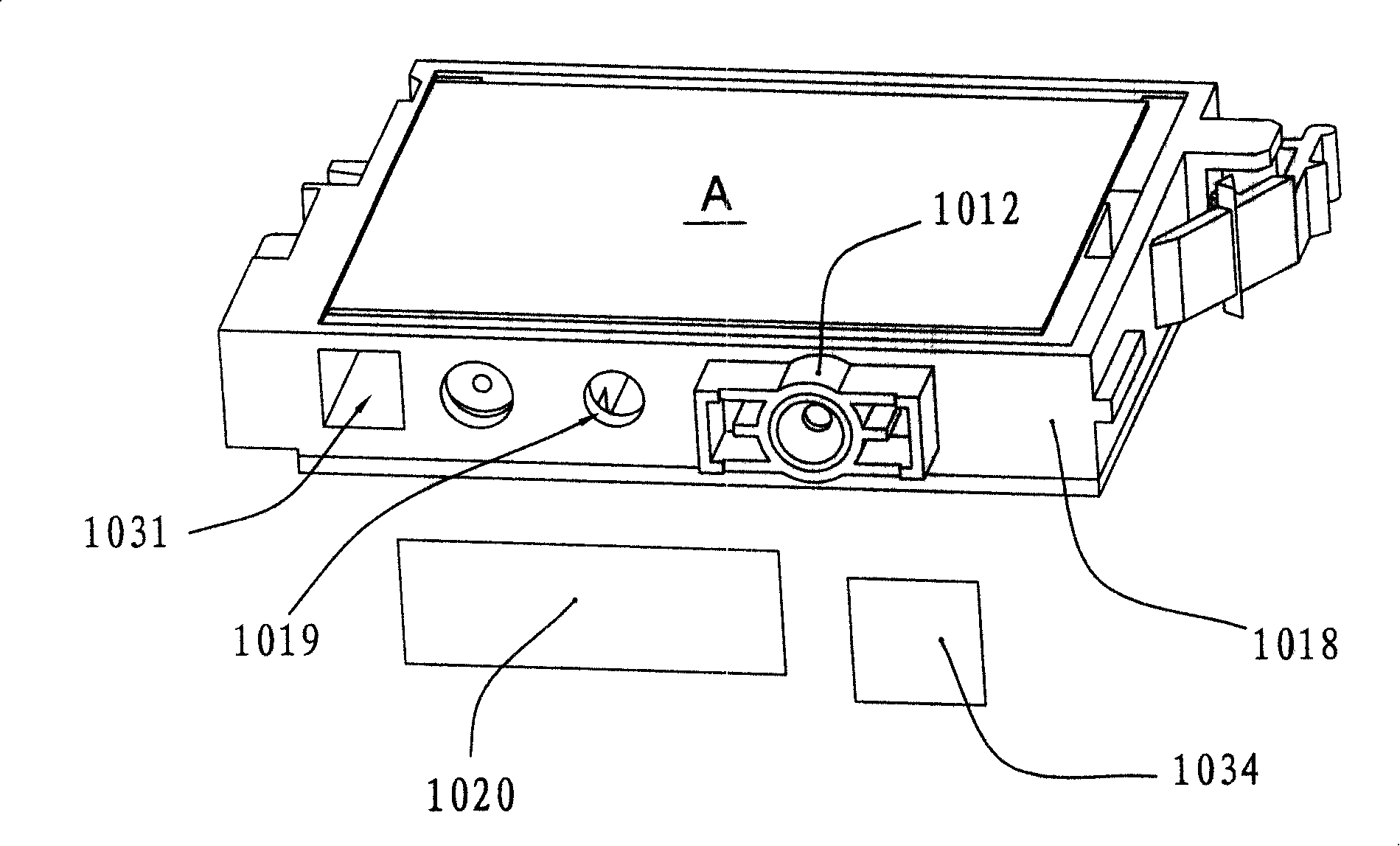

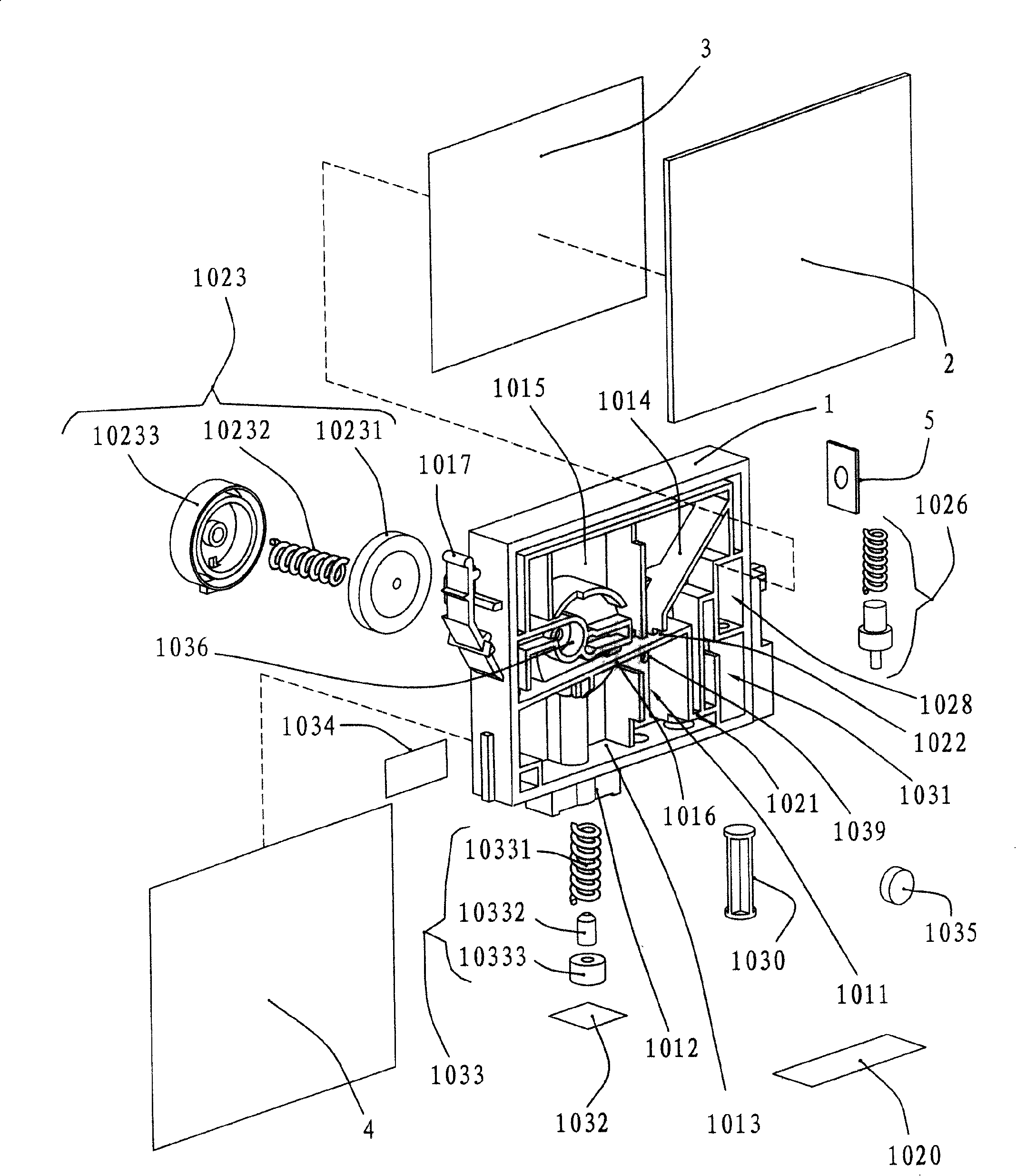

[0034] see figure 1 , 2 , 3, 4, 5, the ink-jet printer ink box structure that regeneration method of the present invention is suitable for. image 3 , 4 In 5, the placement posture of the ink cartridge is the same as that in the working state, and the ink outlets for receiving the ink supply needles of the inkjet printer are all pointing vertically downward.

[0035] The components of the ink cartridge A mainly include: a box body 1, a cover 2, two films 3, 4 and a micro-integrated circuit chip 5 for storing ink information.

[0036] The box body 1 is in the shape of a flat rectangular box, and its longest and widest side wall is removed to be in an open state, forming an opening 1011 . Its interior is separated by several partitions, and the end faces of these partitions facing the opening 1011 are basically on the same plane. An elastic lever 1017 extending obliquely upward is provided near the end of the outer surface of the widest and shortest side wall of the box body...

Embodiment 2

[0060] For the inkjet printer ink cartridge with the above structure, another method can also be used for recycling. The method employs the following sequence of process steps:

[0061] First, on the side wall 1037 whose direction is parallel to the ink flow direction in the ink outlet 102 and whose position is between the ink outlet 1012 and the first one-way valve 1023, open the first ink storage chamber 1013 and communicate with it. Through hole 1038 for external atmosphere (see Figure 4 , 5 ).

[0062] Secondly, remove the residual ink in the inner cavity of the ink cartridge A. The specific measure is to keep the end of the through hole 1038 facing the external environment in a downward facing posture, put the ink cartridge A into a sealed container, and extract the air in the sealed container to the negative pressure inside it. When the value reaches -720mmHg~-750mmHg, keep the pressure for 1 minute to 3 minutes and restore the pressure of the sealed container to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com