Movable joint screw-threaded shaft lifting shifting apparatus

A translation mechanism, threaded shaft technology, applied in conveyors, lifting devices, mechanical conveyors, etc., can solve the problems of complex structure or operation process of the embodiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

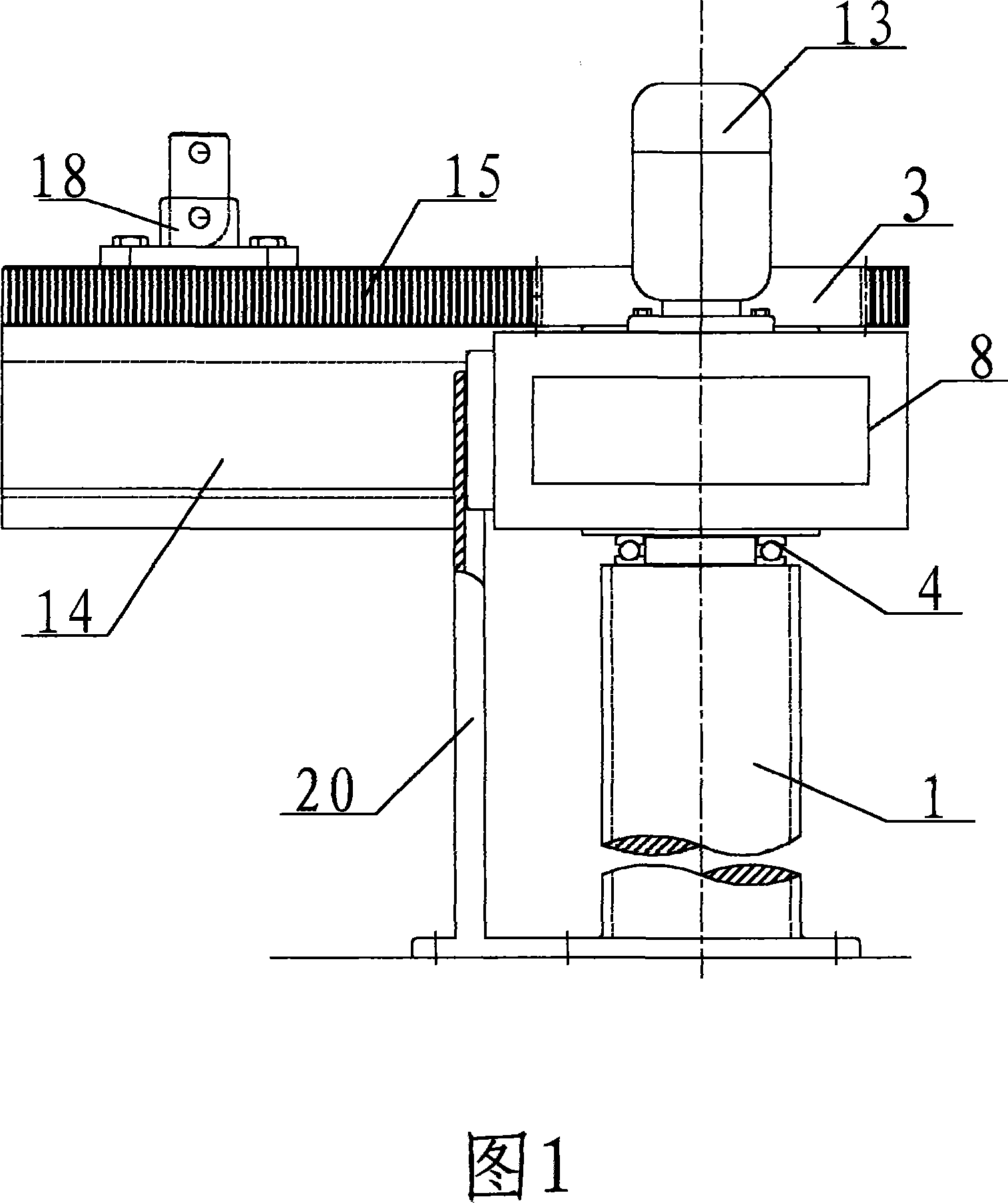

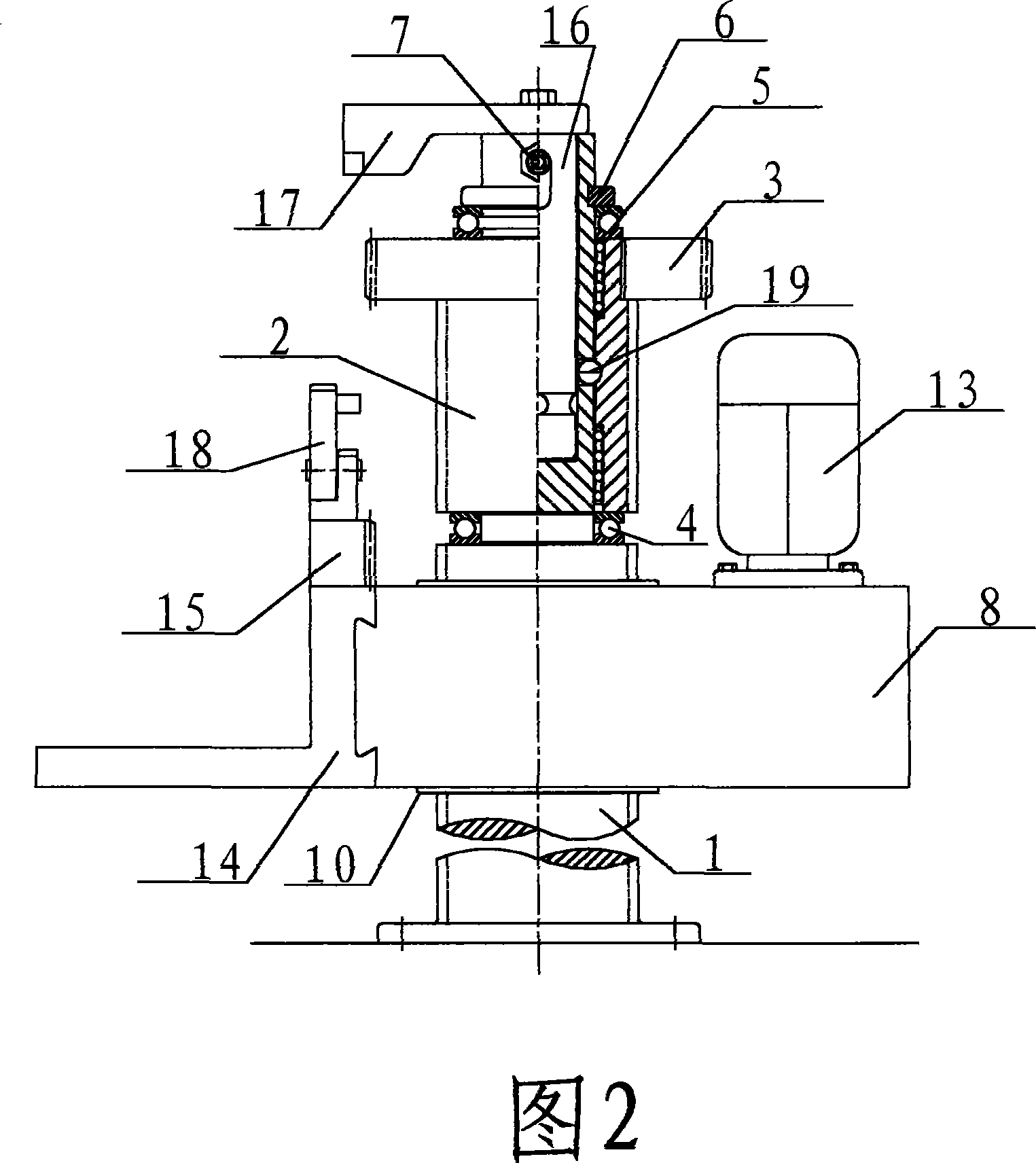

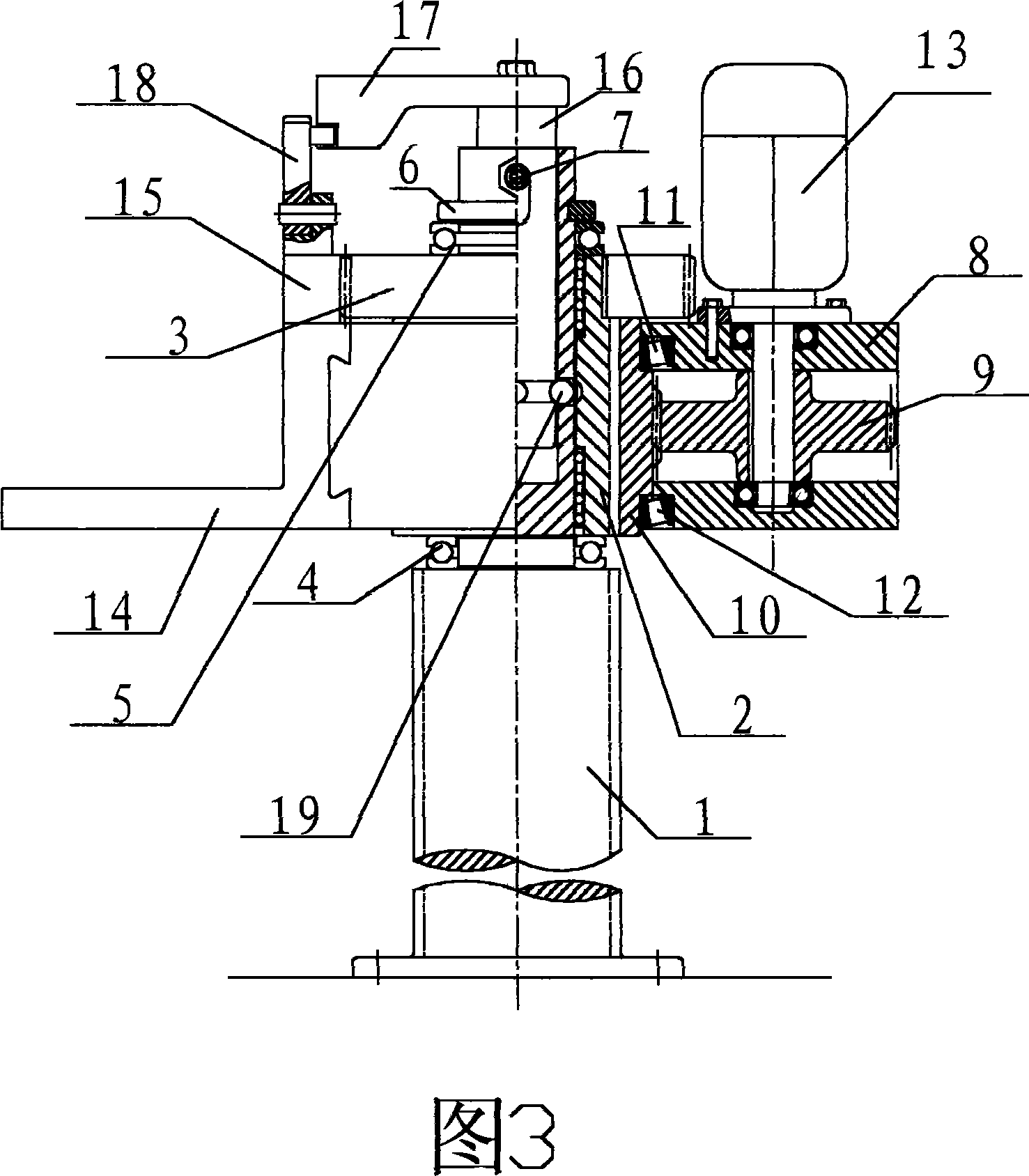

[0038] Embodiment 1: The lifting and translation mechanism of the joint screw shaft, including: the joint screw assembly, the moving box, the bearing platform, the control system, and the vertical guide groove.

[0039]The above-mentioned joint threaded shaft assembly is composed of a fixed threaded shaft 1, a joint threaded sleeve 2, an internal spline gear 3, a lower thrust bearing 4, an upper thrust bearing 5, a snap ring 6, and a magnetic spring bolt 7. The threaded lower end of the fixed threaded shaft 1 is provided with a fixing flange, the upper section is provided as an optical axis section, and the shaft center is provided with a deep hole. The upper ring of the optical axis section is equally divided to form 4 through holes, a circular flat-bottomed groove, and a threaded through hole. Joint threaded sleeve 2, the lower part of the outer circle is set as a thread, and the upper end is set as an external spline. The circle diameter is 0.2±0.1 mm larger than the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com