Method for removing byproduct propyl propionate during preparation process of n-propanol by hydrogenation of propionaldehyde

A technology of propyl propionate and n-propanol, which is applied in the field of removing by-product propyl propionate in the process of preparing n-propanol by hydrogenation of propionaldehyde, can solve the problems of no large-scale n-propanol production device and the like, and can achieve energy efficiency. Low consumption, simple process, and the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

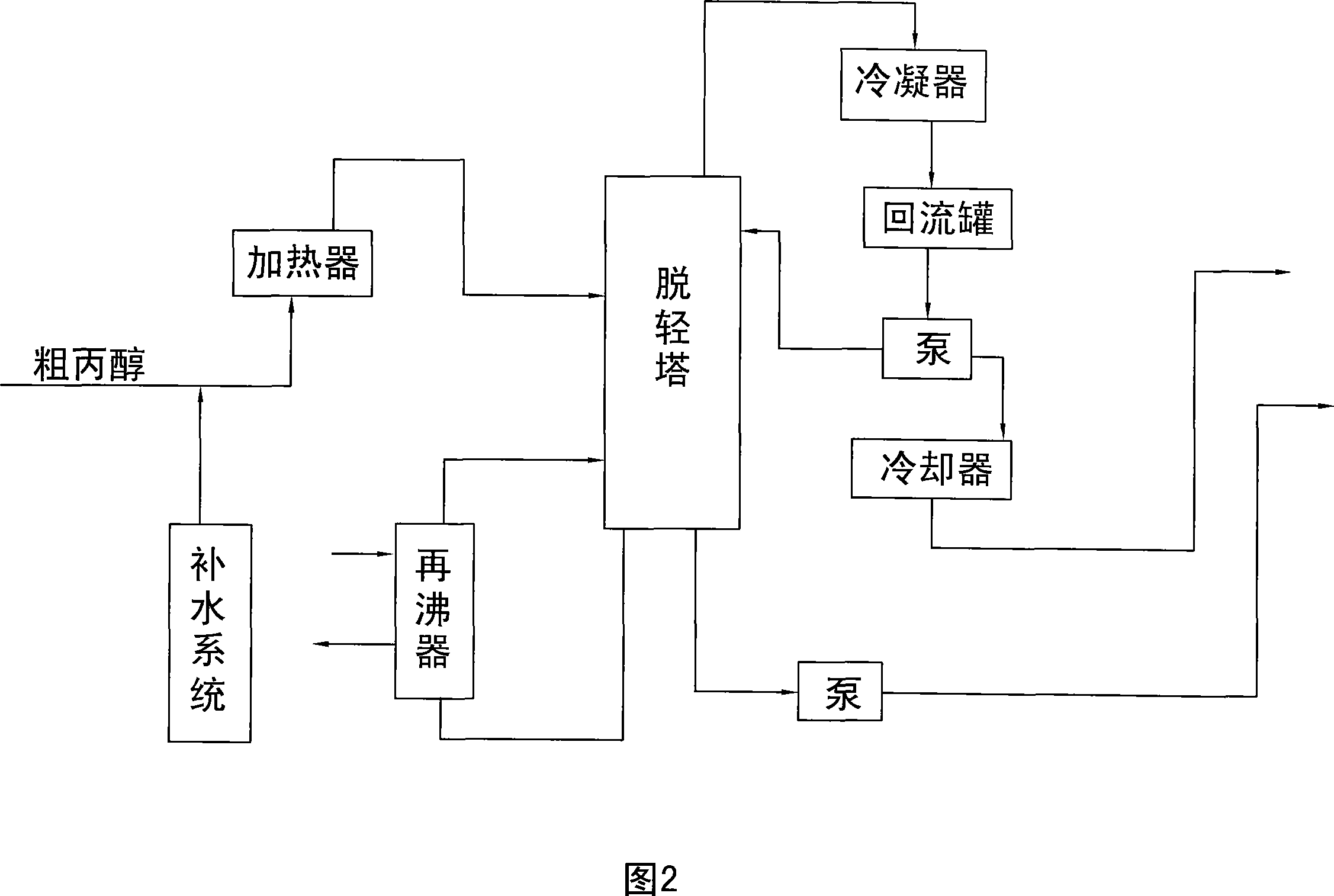

Embodiment 1

[0021] The content of propyl propionate in the crude propanol is 0.3%, and the amount of supplemented water is such that the water content in the crude propanol is 10%. The temperature at the bottom of the light removal tower is controlled at 90°C, and the temperature at the top of the tower is controlled at 75°C. The content of propyl propionate in the final product n-propanol is 0.07%, and the purity of n-propanol is 99.9%.

Embodiment 2

[0023] The content of propyl propionate in the crude propanol is 1%, and the amount of replenishing water makes the water content in the crude propanol 15%. The temperature at the bottom of the light removal tower is controlled at 94°C, and the temperature at the top of the tower is controlled at 80°C. The content of propyl propionate in the final product n-propanol is 0.1%, and the purity of n-propanol is 99.86%.

Embodiment 3

[0025] The content of propyl propionate in the crude propanol is 1.5%, and the amount of supplemented water is such that the water content in the crude propanol is 20%. The temperature at the bottom of the light removal tower is controlled at 96°C, and the temperature at the top of the tower is controlled at 83°C. The content of propyl propionate in the final product n-propanol is 0.11%, and the purity of n-propanol is 99.83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com