Method for producing low basis weight newsprint by 100 percent deinking waste pulp added with retention and drainage agent

A retention and drainage aid, low quantitative technology, applied in the direction of adding non-fiber pulp, processing waste paper, paper, etc., to achieve the effects of shortening drying time, saving production costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Table 1 Net size test data

[0025] sample number

PCD

Zate

#1 White Water Concentration %

#2 White Water Concentration%

Net size concentration%

reserve%

Example 1

-201

-25.1

0.37

0.39

0.95

59.58

Example 2

-175

-18.6

0.37

0.38

0.96

60.73

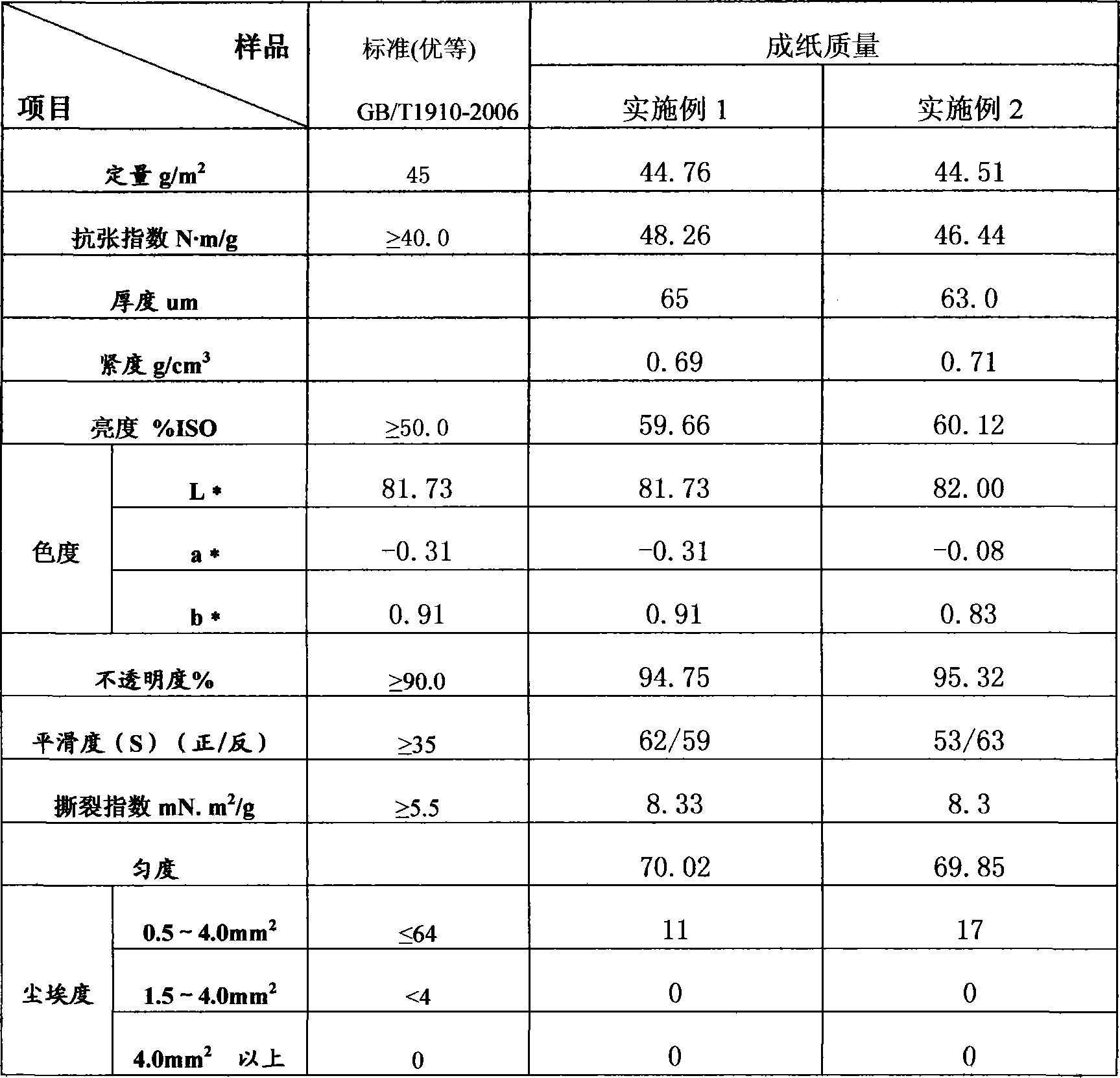

[0026] Table 2 The various quality indexes of finished paper

[0027]

[0028] Example 2

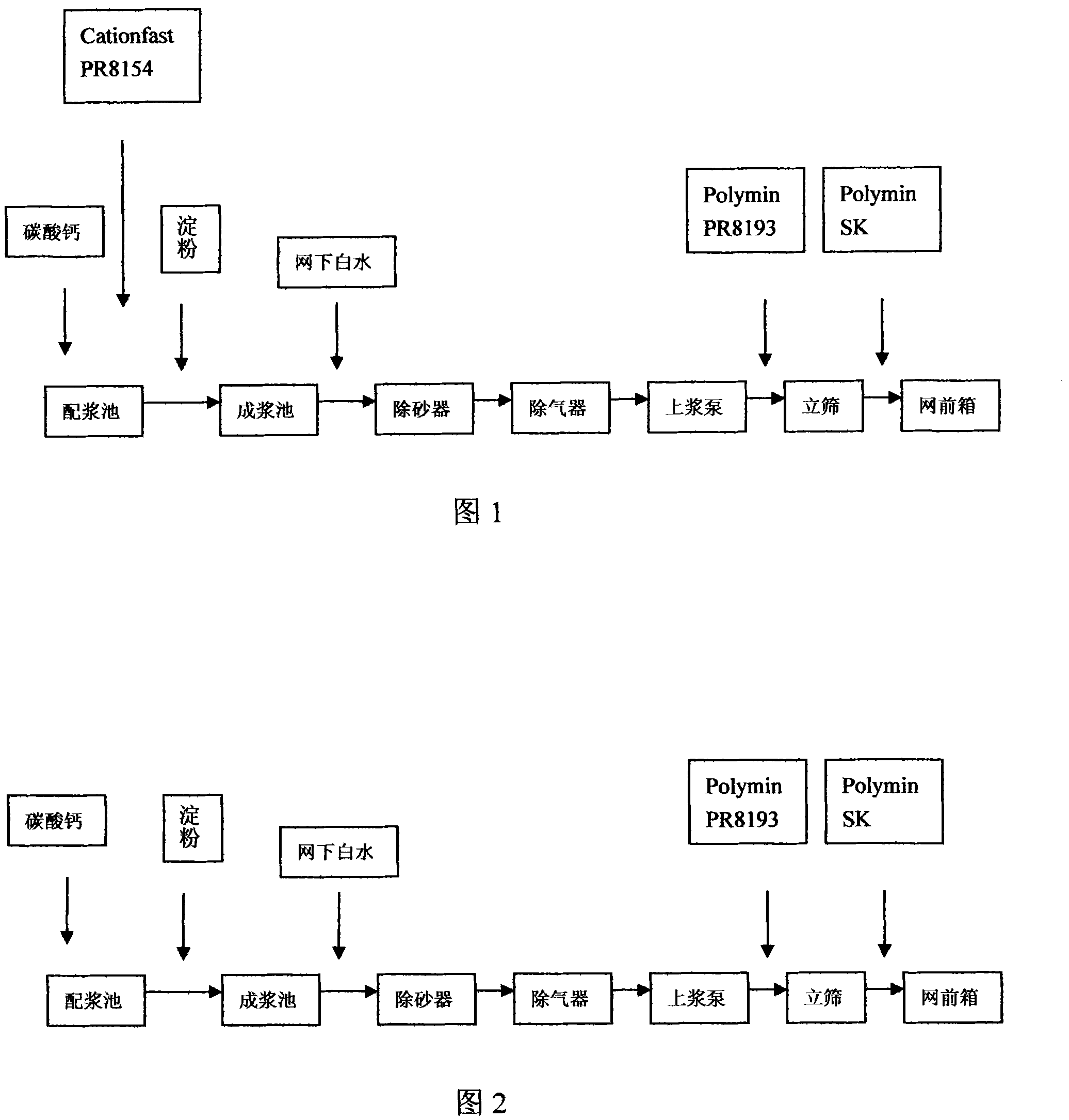

[0029] like figure 1 Shown, the method that adopts 100% deinking waste paper pulp (DIP) to add ternary retention and drainage aid to produce low quantitative newsprint may further comprise the steps:

Embodiment 2

[0031] Table 3 Net size test data

[0032] sample number

PCD

Zate

#1 White Water Concentration %

#2 White Water Concentration%

Net size concentration%

reserve%

1#

-211

-23.2

0.36

0.38

0.98

57.67

2#

-185

-17.3

0.35

0.37

0.97

59.38

[0033] Table 4 Various quality indicators of finished paper

[0034]

[0035] Example 3

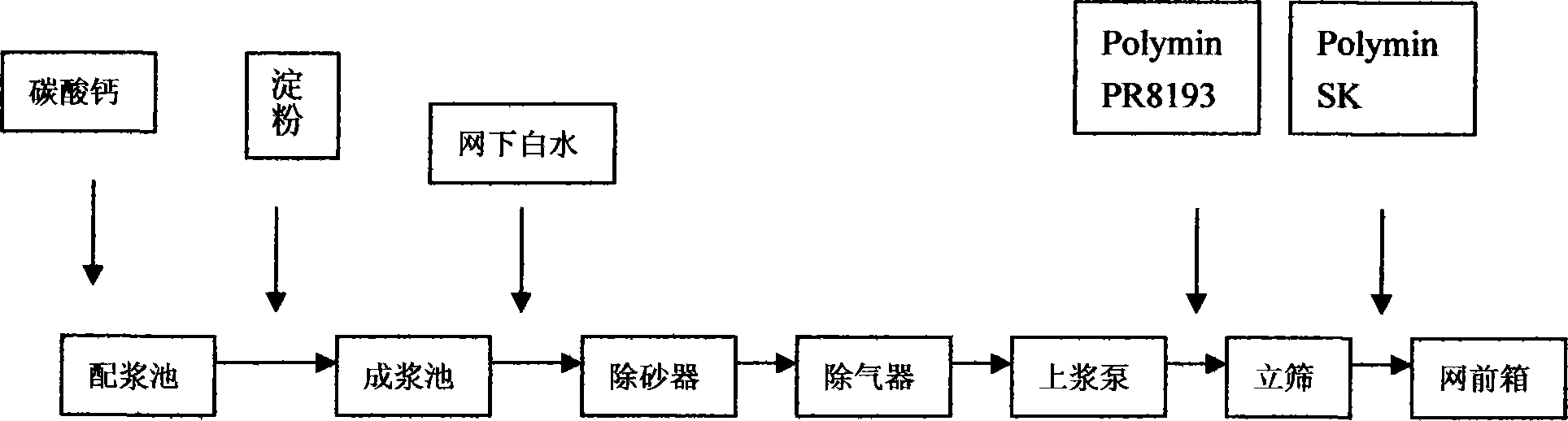

[0036] like figure 2 Shown, adopt 100% deinking waste paper pulp (DIP) to add the method for binary retention and drainage aid to produce low quantitative newsprint, comprise the steps:

Embodiment 3

[0038] The above-mentioned embodiment is a preferred embodiment of the present invention, but the embodiment of the present invention is not limited by the above-mentioned embodiment, and any other changes, modifications, substitutions, combinations, Simplifications should be equivalent replacement methods, and all are included in the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com