Loading planning type retaining wall block

A retaining wall, stowage technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of high transportation cost, difficulty, increase project cost, etc., and achieve simple and lightweight construction of walls. Light and easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

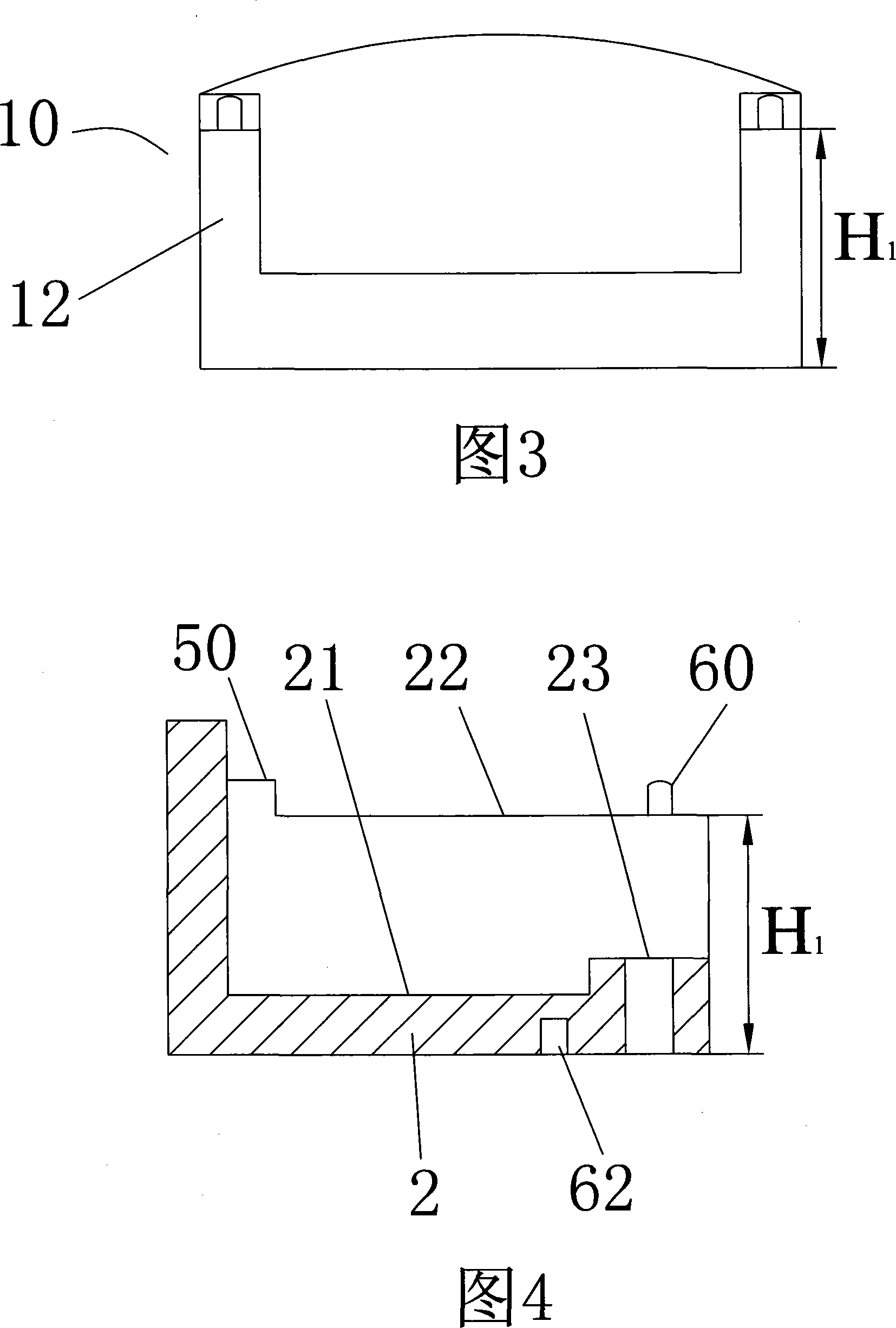

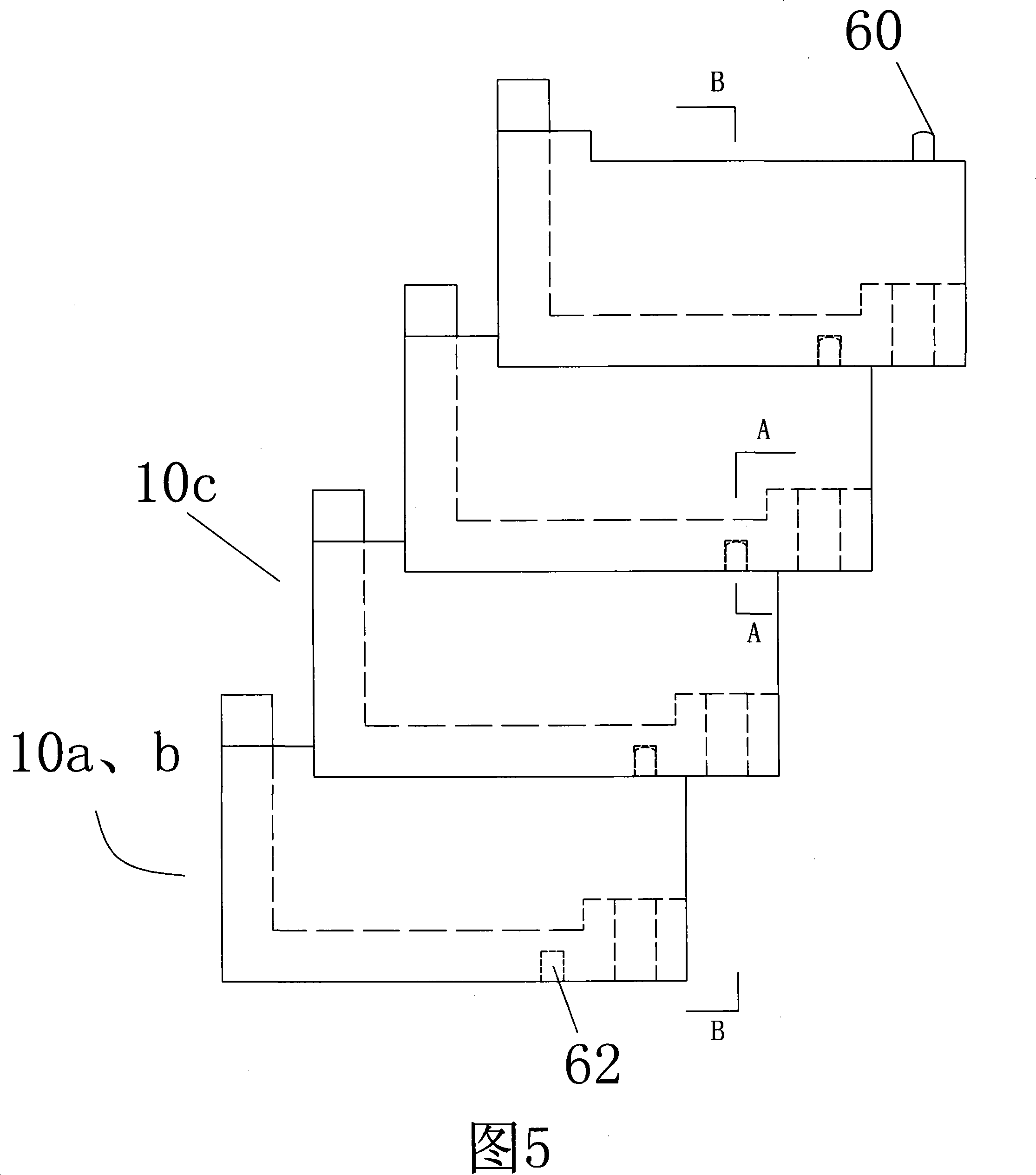

[0025] As shown in FIGS. 1 to 4 , the stowage retaining wall block 10 includes a face wall 1 , a bottom plate 2 , and left and right side walls 3 , 4 . The stowage retaining wall block 10 is made of a suitable polymer material, such as polyethylene that is easy to mold. Width W of stowage retaining wall block 10 1 (Fig. 2) is the distance between the outer surfaces of sidewall 3 and sidewall 4; height H 1 (Fig. 3, 4) is the distance between the bottom surface 21 of base plate 2 and the side wall top surface 22; Length L 1 ( FIG. 2 ) is the distance between the front surface 11 of the face wall 1 and the rear surface 12 of the side walls 3 , 4 . The face wall 1, the bottom plate 2, and the side walls 3 and 4 enclose a backfill cavity 5 (Fig. 2), which can be backfilled with solid backfill such as various soil bodies and construction waste during wall construction. The length, width and depth of the backfill cavity 5 are respectively the block length, width and height minus t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com